News & Blogs

Stay updated with the latest news, insights, and expert blogs from Emixa. Explore industry trends, digital innovations, and company updates all in one place.

- PLM

The Digital Machine Shop: The Road to Shorter Production Times

The Digital Machine Shop helps companies stay competitive, design the right products, and find the best way to manufacture them. This data-driven environment transforms production and the business by seamlessly connecting all elements of your operations, such as processes, machines, robots, and people. This model includes a fully digitised, faster production process - ranging from preparation to the final manufacturing of products or components. A model that can be used in all industries including aerospace, medical devices, and industrial machinery manufacturing. The Digital Machine Shop includes two processes: the manufacturing process and the inspection process. A component model designed in CAD software is the starting point for executing these processes. In the first step of the manufacturing process, preparations are made to turn the component model into a milled product. This involves looking at positioning, material use, and the steps to be performed. This is the preparatory phase for step two: programming the milling paths. In this step, a milling programme is created by CAM software through different operations. This NC programming provides the basis for controlling the machine. To prevent errors and to set up the milling process in an optimal way, the milling paths are simulated. A 3D simulation sets the machine in motion virtually to predict the milling process and detect and resolve errors early. At the same time as implementing the Digital Machine Shop method, the measurement process starts. In this stage, a virtual measurement takes place, which can be performed using CMM software that controls the automated measuring machine. A measurement plan is created with the help of PMI data to formulate the necessary measurement values. The probe path of this measurement plan is then programmed as the next phase in the process. To check the feasibility of this probe path, it is virtually set in motion by 3D simulation and adjusted where necessary. Benefits of the Digital Machine Shop: Increased machine utilisation Reduced machine cycle time Faster set-up Precision Machining Improved quality inspections Enables more complex products Innovative technologies New business models In the Digital Machine Shop, Siemens software ensures seamless information flow throughout the entire production process, eliminating the need for transitions between different software systems. Any changes made at the start of the process can easily and quickly be implemented in the final step. Using the same model for the production process ensures faster and more effective operations. If you have a machine shop, you know production time is crucial. Digital automation of production achieves first-time-right to shorten throughput time and accelerate time-to-market. If you aim to optimise and accelerate your production process, the Digital Machine Shop is your ideal starting point! Would you like to learn more on this topic? Download the eBook on the roadmap to a Digital Machine Shop or watch our webinar on getting more out of your current machinery!

- PLM

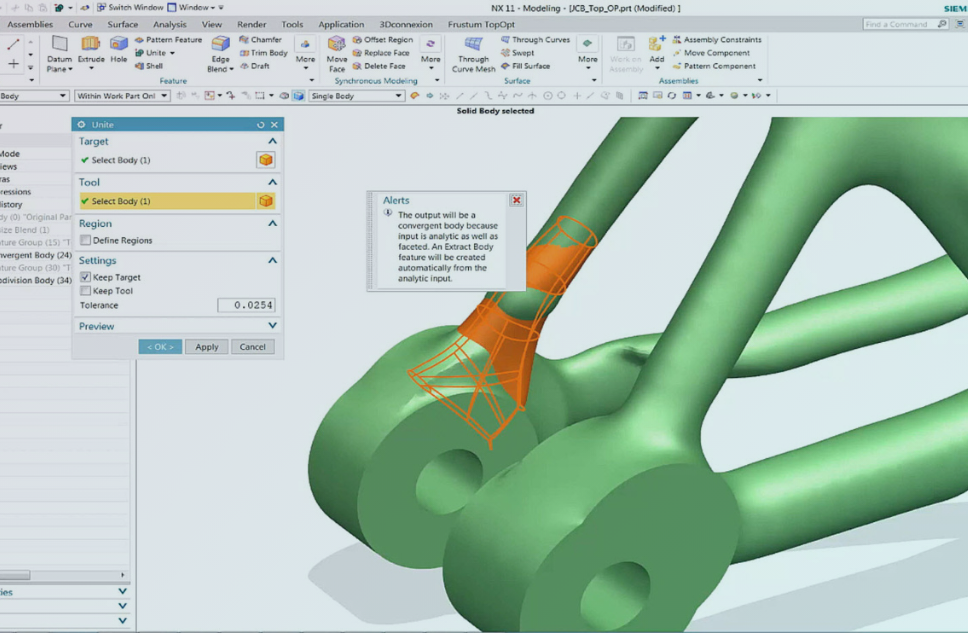

Reap all the Benefits of Additive Manufacturing

Companies are challenged every day by their customers with requests for more complex products, in smaller batches, with shorter lead times and at lower prices. An almost impossible ask, but if your competitor can deliver, you can't fall behind. Innovative technologies like Additive Manufacturing (AM) can improve and streamline your processes. When used correctly, AM offers numerous advantages over conventional production technologies. It brings about a revolutionary shift in the way we manufacture parts across various industries, catering not only to big businesses but also to small and medium enterprises. Additive Manufacturing in the product lifecycle Additive Manufacturing, also called 3D printing, has existed for over 35 years. But considering we've used conventional tech like subtractive and forming processes for thousands of years, you could say we've only just begun tapping into AM's potential. Starting in the '80s as a rapid prototyping tech, it's now increasingly used across the product lifecycle. Diverse applications need different materials and processes. Luckily nowadays there are printers that easily switch materials, vastly expanding possibilities. With professional, affordable desktop 3D printers you can print most of your prototyping and tooling applications quickly, cheaply and in-house. For some applications, it's even possible to print end-use parts or spares. Prototype 3D print your visual and functional prototypes to detect issues earlier, test new features and cut down time-to-market. Tooling Through the printing of production tooling, the ability to craft custom tools becomes a faster, more cost-effective, and in-house possibility. But the real value lies in the impact these custom tools can have on your processes, making them more efficient, rapid and safe. Production part Using 3D printing as a production technology to manufacture end-use parts makes it possible to create components that would be impossible with conventional manufacturing methods. Spare parts By 3D printing your spare parts on-demand, you can reduce inventory, storage space, and waste. Combining this with on-site printing also lowers transportation and packaging costs. Benefits of Siemens NX™ Additive Manufacturing Greater design freedom Customisation, enabling lot size 1 Utilisation of only essential materials Part consolidation and function integration Enhanced performance Metamaterials Print "on-demand" and "on-location" Industrial Additive Manufacturing For advanced applications, industrial 3D printers are sometimes the best solution due to specific material needs, build volume, capacity or resolution. An increasing number of companies successfully print a wide range of apps across sectors. But AM isn't a standalone process - upstream and downstream procedures must be considered too. Design for Additive Manufacturing (DFAM) Every production process has design rules and tools. As "Additive" is the very opposite of conventional "subtractive" manufacturing, traditional design tools don't always give the needed results. You don't remove material from a block, only adding it where necessary. That's why Siemens NX developers have added new design capabilities in recent years, helping designers fully harness AM's potential. AM Build Preparation & Simulation In 3D printing, the orientation of a part in the printer plays a crucial role, affecting strength, quality, costs, print times, material usage, and post-processing. Siemens NX's Build Preparation functionality offers orientation guidance, allowing you to save the desired orientation directly in the CAD model, ensuring consistent and repeatable outcomes. CNC Post-Processing Once your metal print is complete, the removal of metal supports is still necessary. Manual removal can be labor-intensive and lacks repeatability. This process can be automated via CNC milling, automatically eliminating supports and ensuring correct dimensions and surface finish. Programming and simulating the milling process can also be done in Siemens NX, preventing collisions and milling issues. Whether you're new or experienced in 3D printing, just exploring its potential or running industrial printers 24/7. We're here to support your business every step of the way to successfully implement Additive Manufacturing.

- Tecnomatix

How to Cope with (Over)full Warehouses?

Effectively managing (over)full warehouses poses a significant operational challenge. Warehousing inherently involves complexities, and the current trend, particularly in areas like the hinterland of the port of Rotterdam and other strategic logistics hubs, is the accumulation of goods leading to warehouses reaching maximum capacities. This makes it harder to work efficiently and comes with its own set of problems. That raises the question: ‘how to cope with (over)full warehouses?’ This development is partly a consequence of the aftermath of the COVID-19 crisis. During the lockdowns, dining out and in-person shopping were restricted, but online ordering of goods was unrestricted. This resulted in a high demand for various products, causing the logistical system to struggle to meet the demand. Businesses and retailers procured their merchandise well in advance, resulting in the saturation of all distribution centres in the hinterland of major ports and, more recently, inland terminals, with goods ordered ahead of schedule. If current demand and buying confidence were still as robust as during the pandemic, this might not be a major concern. However, the combination of inflation and soaring energy prices has made people more cautious about their spending. As a result, goods are staying in warehouses longer than usual, causing efficiency and optimisation challenges in warehouse management. While companies have limited control over macroeconomic factors, they can secure a competitive edge by concentrating on optimisations in their warehouse layout and/or operational methods, enhancing the flow of goods within their warehouses. Read on to find out how to cope with (over)full warehouses and the role Emixa can play in improving processes in warehouses. Practical problems in coping with (over)full warehouses The accumulation of goods confronts warehouses with various practical problems. Many warehouses do not actually earn their money through storage itself, but above all by repacking, labelling and distributing goods. As a result, any lack of turnover and the steady accumulation of products in the warehouse threatens their business model and profitability. Moreover, there are negative consequences for daily operations within the workplace. For example, warehouse utilisation of 90 to 98 percent means that warehouse teams are less efficient. Forklifts are required to lift goods to greater heights, and numerous products are positioned in challenging or harder-to-reach spots outside the racks. The result is that pickers and forklift operators need to cover more distance, resulting in less efficient routing and delays, further prolonging the storage of goods. Locating and gathering the correct items also becomes more challenging, contributing to delays in deliveries. Ultimately, there's a risk at the end of the chain where retailers may need to discard products that have been sitting on the shelves for too long. The aforementioned issues not only compromise efficiency but also have negative effects on employees. They find themselves working overtime more frequently and with less enjoyment. The likelihood of fatigue and overburdening increases, resulting in additional costs and staff shortages. Finding sufficient personnel is already challenging in the current tight labour market. In summary, no one benefits from an excessively high fill rate in the warehouse. The digital twin Evaluating potential solutions to enhance operational efficiency in a warehouse carries inherent risks. The proposed idea may succeed, fail, or require multiple attempts before achieving the desired outcome. Regardless of the result, these attempts consume valuable time. Utilising advanced simulation software mitigates these risks. A realistic, interactive digital twin of your warehouse allows for the virtual testing of ideas and scenarios in a digital replica. This well-established technology, initially used for virtualising production lines and entire factory setups, has been extended to optimise warehouses due to the close connection between production and logistics. Years ago, we applied this expertise to enhance warehouse efficiency. Altering walking or driving routes to improve the efficiency of pickers and expedite order completion? Changing the warehouse layout and pathways to facilitate easy access for forklifts to pallets and boxes? Optimising the existing space? With plant simulation, you can virtually experiment and compare multiple options, scenarios, and warehouse layouts. This way, you can quickly determine the most efficient working method. How Emixa can help Emixa can assist companies with warehouse management and optimisation. “Using the ‘digital twin’, true-to-life, complex simulations are possible. This enables our clients to maximise efficiency from their warehouse capacity,” explains Nick Peeters, PlantSim Expert at Emixa. “The expertise of Emixa in both the manufacturing and logistics/warehousing sectors, combined with our in-depth knowledge of the Mendix platform for developing specialist low-code applications for logistics and warehousing, make Emixa Industry Solutions and Emixa Applications Solutions a very valuable partner for our clients,” says Ruben van der Leer, Account Executive at Emixa Applications Solutions. “Thanks to low-code and integration, you can achieve a level of efficiency that would not have been possible a few years ago.” Most warehouses work with automation from various suppliers and a wide variety of partners within the logistics chain. The solutions and knowledge of Emixa Industry Solutions ensure that all those different cogs are represented in one system. In this way, they produce a dynamic layout of your logistics system, providing insight into the entire system. Because many logistics companies need to allow for growth in capacity, maintaining oversight is the most important thing. By tuning the performance of subsystems to one another, you avoid suppliers and partners sending you from pillar to post. One of Emixa Industry Solutions’ specialities is simulating warehouses and the systems they use. By simulating systems, potential improvements and different scenarios and solutions over time, your organisation can instruct employees and partners in detail to implement the necessary optimisations. Want to learn more about managing (over)full warehouses? For a smooth flow of goods, warehouses are partially reliant on economic factors beyond their control. Nevertheless, a well-designed, modern, and flexible simulation and optimisation system provides more opportunities to maintain service levels, control fill rates, and streamline warehouse processes efficiently. But it all begins with insight. Curious how Siemens & Mendix solutions, combined with our expertise, can support you in this matter? Please feel free to contact us for more information and expert advice.

- Industry 4.0

Is your Company Making a Difference with Model-Based Definition?

Digitisation is progressing rapidly everywhere. Manufacturing companies also face this challenge now more than ever. To be digital, or not to be. In the shift to digital, traditional 2D drawings are giving way to Model-Based Definition (MBD). Has your company made the essential move towards Industry 4.0?

- Plant Simulation

Transforming from Static Blueprints to a Dynamic Digital Factory

Van Wijnen is a Dutch company in the construction sector, committed to environmentally friendly building for the next generation. Operating from 25 locations across The Netherlands, Van Wijnen is involved in the development, construction, management, and maintenance of buildings and homes. With the high demand for housing in The Netherlands and a shortage of affordable homes, Van Wijnen recognises the need for a different approach to construction. The scarcity of skilled workers in the industry further intensifies the challenges in housing construction. To address these issues, Van Wijnen is increasingly focusing on industrialised construction, aiming for faster, more cost-effective, cleaner, and circular building methods. A digital production process To meet the high demand for housing in the coming years, a substantial number of homes need to be built. Van Wijnen's goal is to realise 4,000 homes per year in the upcoming years. To achieve this, Van Wijnen has invested in a dynamic (or in other words: digital) design, development, and production process. This digital production process takes shape in a greenfield housing factory. In this future factory, there are large steel tables on which a mould is built using a robot. By using a high degree of robotisation, the problem of skilled worker shortages in construction is also partially solved. The tables with moulds move like a carousel through the factory. At each point where the table stops, value is added, such as reinforcement steel, electrical boxes, window frames and structural lifting and coupling facilities. After adding all the components, concrete is poured, and elements like walls, facades, or floors are prepared. These elements are then put in a controlled environment to cure, all part of an automated process. On-site teams later assemble these components, maintaining a rapid pace, completing one home or two flats each day. This automated process, with its scale and variety, ranging from ground-based homes to flats and gallery flats, all produced in a single housing factory, stands out as unique in the construction industry, not just in the Netherlands but beyond. The added value of simulation Simulation serves a crucial role in assessing the viability of an automated process designed to manufacture prefabricated elements for 4,000 homes per year. By transforming the initial static layout drawing into a dynamic scale model, different scenarios can be evaluated. Siemens Tecnomatix Plant Simulation allows Van Wijnen to analyse the manufacturing facility's capability to produce a significant number of components within the desired timeframe. This simulation involves replicating the plant, production floor, machinery, and personnel to examine and validate production changeover times. With various machines assigned different tasks, aligning them seamlessly becomes essential. This software empowers Van Wijnen to optimise machine configurations successfully, ensuring the achievement of the goal to manufacture 4,000 homes each year. "Through our simulations, we gained early insights into the optimal machinery layout. The dynamic factory simulation helps uncover potential errors, allowing for early identification and resolution of bottlenecks. This not only instils confidence but also offers the flexibility to test optimisations cost-effectively." - André Klouwen, Deputy Director of Technology at Van Wijnen Components Save costs and maintain oversight An increasing number of companies establishing a greenfield production facility opt to simulate a dynamic version of the future factory or production hall before its physical construction. The ability to foresee and test the flow of your factory in advance, ensuring that your machinery and desired production can be realised. Knowing the required number of operators to achieve the projected and determined production levels. Despite the complexity of the process, Siemens Tecnomatix Plant Simulation can preserve clarity and save costs. We are very proud to be part of the future of living! While prefabricated homes have been around for some time, they haven't been produced at this volume. Tecnomatix Plant Simulation is the solution for intricate processes, transitioning from static drawings to a dynamic, digital version of your factory! Would you like to get started with a simulation of your production environment? Contact us directly.

- PLM

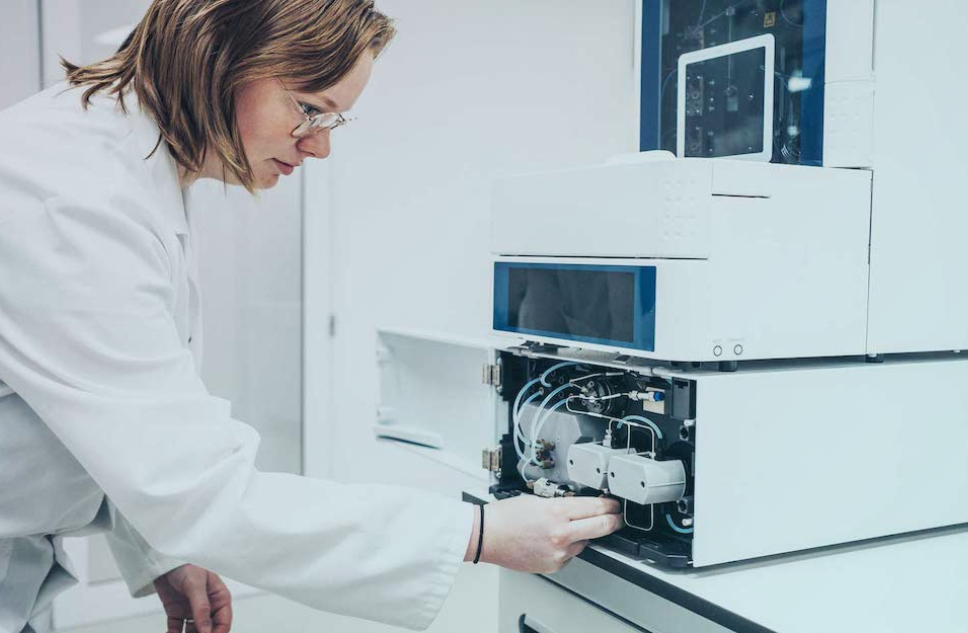

Coherent Project Documentation with Polarion

Spark Holland is a supplier of innovative sample introduction, extraction, and separation technology for analytical systems such as HPLC, MS, GC, and NMR. Spark gathers user feedback and seeks to understand typical issues in the analytical laboratory, focusing on product development towards simplicity and reliability. To create products that prioritise simplicity and reliability, it's essential to use a user-friendly, open, and easily understandable tool for requirement management. Shifting away from disjointed documents and spreadsheets, which previously formed the foundation of requirements management, became a challenge as projects grew more complex, making traceability nearly impossible. In a proof of concept, Polarion not only addressed the traceability issue immediately but also led the team to reevaluate the development process, resulting in a simplification step. Polarion Application Lifecycle Management enables teams to collaborate easily and securely on shared documentation. You can define who can see what, who can make changes, and when, through detailed permissions and robust configurable workflow automation. Additionally, Polarion has an FDA-approved electronic signature process. "Emixa Industry Solutions has consistently demonstrated expertise and reliability in addressing our Product Lifecycle Management needs over the years. Including them in our shortlist of vendors was a logical choice due to their knowledge and ability to meet customer requirements precisely. Their extensive partner network enables them to address any gaps in demand." - Nils Reuvers, IT Manager at Spark Holland B.V. The implementation of Polarion has resulted in more streamlined, improved, and cohesive project documentation with comprehensive, readily accessible traceability, all while minimising administrative overhead. Polarion has facilitated easier compliance with legal standards and regulations, creating clarity and improving the working process within product development. Want to learn more about this? Contact us.

- Tecnomatix

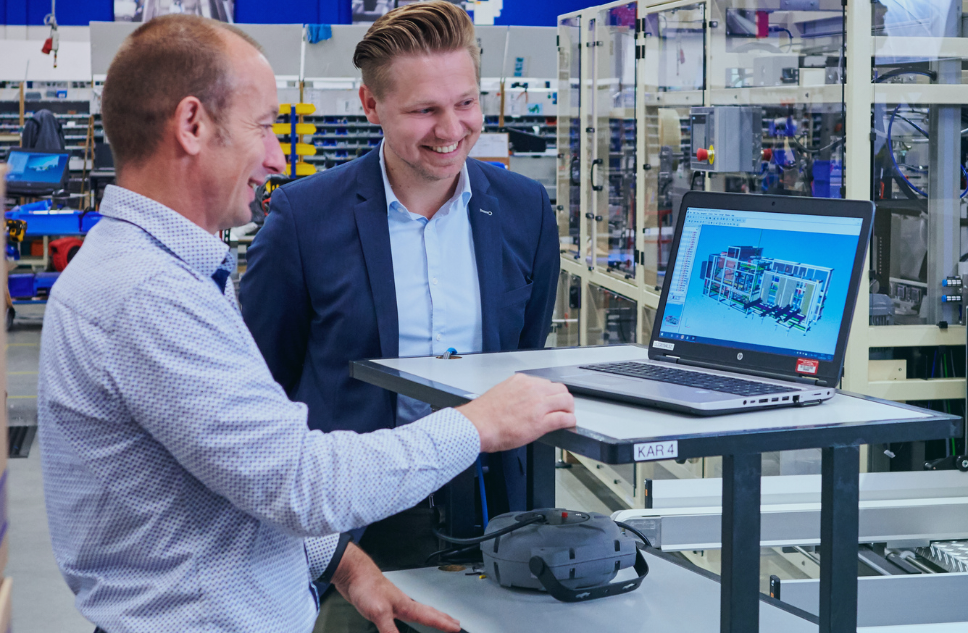

The Benefits of Virtual Commissioning of Machines

As market demands for new products intensify, production companies face the challenge of adapting existing lines and commissioning new machines faster. Digital models offer a solution by allowing testing and validation even before the physical systems are installed. The key focus here is time savings, a critical factor in the highly competitive manufacturing landscape. The market's increasing demand for new products and variations shortens product life cycles, emphasising the need for reduced time-to-market. This time pressure extends to machine or line builders and high-tech suppliers, requiring fast delivery of new machines and adapted production lines. To meet these demands, companies are implementing complex systems and automation, leading to a growing presence of electronic components and control code. Before adding a new automation system to your manufacturing process, it's crucial to thoroughly check and test it. This ensures that the mechanical and electronic components in the control system work together seamlessly. Errors show up too late Discovering errors too late is a common challenge in the traditional commissioning process. The preparation for commissioning, involving checks and tests, is typically a physical procedure conducted on the actual machines. Consequently, commissioning occurs at the end of the development cycle, post-engineering and production completion. When errors surface at this stage, rectifying them often demands a substantial amount of time and financial resources. Identifying these problems earlier in the process could have led to quicker and more cost-effective solutions. And that's not to mention the extra pressure imposed by the client when the project is delayed. The client then cannot start production as planned and inevitably loses a lot of money. Another scenario involves adapting an existing production line, which requires a halt to make necessary component adjustments and conduct a test run. This interruption has considerable effects, causing production delays and significant time losses during testing. In practice, we see that many companies still follow this conventional approach, conducting machine or line commissioning on-site. This leads to considerable time loss compared to competitors who conduct digital commissioning tests. With a digital model, a digital twin of the production line or machine, companies can virtually simulate line adjustments or the integration of a new machine. Virtual commissioning In virtual commissioning, the written PLC code is linked to the virtual model instead of the physical one. This allows the validation of the entire line or machine operation at an early stage, with engineers visually observing the machine's performance. This visual aspect proves crucial in identifying minor errors or problems that might otherwise go unnoticed. If issues arise in the simulation, it is possible to quickly adjust the necessary elements within the digital model. This approach enables checking and adjusting the complete process control virtually before proceeding to the actual on-site construction once everything is in order. Digital models provide advantages for clients as well. They gain insight into the machine's eventual operation at an early stage, ensuring clear communication and refining client requirements early in the process. It also allows clients to train employees worldwide to operate the machine before the physical machine is built. Utilising the digital twin for designing, validating, and commissioning a line or machine has numerous benefits, including: Reduction in the total development time of each project Shorter commissioning period Reduction in total costs Importantly, this method not only results in significant time and money savings but also allows the existing line to continue production during the adaptation phase. It also ensures better scheduling and execution of the actual, physical adaptation of the line, minimising the impact on production staff. Get in touch Shifting to virtual testing and setup is a big move. At Emixa, we take a practical step-by-step approach. Curious to learn more? Contact us, and we'll provide further details.

- Industry 4.0

Do Machine Factories Risk Becoming Redundant?

Blackberry, Blockbuster and Kodak. History is filled with companies that were once leaders in their own industries, but were eventually overtaken by competitors or even ceased to exist entirely. The common thread in their downfall? They failed to adapt to the fundamental shift in expectations from the market and demand from the customer, driven by competitors who made use of the latest technology. Blackberry, a pioneer in mobile phones, confidently optimised the QWERTY keyboard and scroll wheel. Meanwhile, Apple conquered market share with an innovative touchscreen and mobile operating system. Blockbuster, the company where you could rent films in physical stores, did not adapt itself in time to the changing business models and new technological possibilities that Netflix did take advantage of. Kodak, the pioneer of digital photography, hesitated to move away from traditional film activities, allowing competitors like Sony, Nikon, and Canon to seize the opportunity and advance the invention. The mentioned companies faced challenges in the initial years of digitisation, a trend that has now permeated almost all industries, reshaping both products and production processes. Presently, leading organisations are actively refining their digitalisation strategies, considering how products and services are developed, produced, and enhanced. Both large and small manufacturers must adapt The latest wave of technologies, Industry 4.0, gives a new meaning to service, competition and customer expectations across the entire Supply Chain. From small businesses to industry leaders. Industry 4.0 makes it possible to integrate digital technologies into all business processes, creating an 'End-to-End Platform' that seamlessly connects the virtual and physical worlds. Digital twins, virtual representations of products and production processes, are connected via a digital thread: An always available, accessible feed of real-time data. This digital thread is available to everyone at any time and allows product and production engineers to work simultaneously because they have immediate access to the information they need. Industry 4.0 transforms modern machine factories no less than new technologies transformed the mobile phone, film distribution or photography industries. However, recent research suggests that many machine factories are not well prepared for this. Of the machine factories surveyed: Over 50% still rely on standalone CAD and CAM systems Less than 30% manage and control their data Around 75% rely on disjointed CMM systems 61% still use paper documentation Only 37% use 3D printing in production The virtual Supply Chain is about businesses, not technology Too many machine factory owners believe that strategies that helped them in the past will also bring success in the future. Expertise in production was the competitive advantage for many machine factories, but expertise alone is no longer enough these days. As essential parts of an increasingly global supply chain, machine factories must shift their traditional focus to a customer-focused one, producing products faster and better than ever before, where and when the customer wants. A digitisation strategy is not just about showcasing new technologies, although it is often presented that way. Digitisation is about a robust business strategy, aiming to lead a successful production operation. Machine factories that apply Industry 4.0 technologies are better prepared to: Secure orders globally by delivering high-quality products faster, outpacing competitors. Increase margins through investments in new processes rather than tinkering with outdated ones. Enter new markets with a focus on innovation and growth. Embrace new manufacturing technologies such as Additive Manufacturing, advanced robotics and automation, and emerging technologies like Artificial Intelligence and Virtual Reality. It is important to note that Blackberry, Blockbuster and Kodak did not fail because they did not realise how new technologies were transforming their industry, or because they did not adapt. They failed because their response was not aligned with the challenge. An article in the Harvard Business Review, "Why Good Companies Go Bad," explains: "Managers of endangered companies typically identify the threat early, thoroughly analyse its implications for their business, and initiate a flurry of initiatives in response. However, despite these efforts, the companies continue to struggle." “The problem is not an inability to take action, but an inability to take appropriate action.” Incremental technological advancements merely address issues from the past decade, failing to tackle fragmented processes and disconnected data across design, engineering, production, and quality. Explore options step-by-step Machine factory owners often perceive Industry 4.0 as beyond their reach. It is deemed too expensive, time-consuming, and disruptive to ongoing operations. Yet, it's feasible to embark on a gradual journey towards Industry 4.0 transformation. At Cards, we assist companies with a well-crafted strategy and planned implementation that considers immediate ROI and integration with existing business processes while accelerating organizations on the path to digitalisation. Bottom Line Machine factories confront new challenges shaped by evolving market expectations. Customers no longer tolerate errors or delays, and demand responsiveness beyond the capabilities of inefficient production processes. In response, machine factories must adopt an end-to-end solution; failure to do so risks falling behind the competition. Curious about the benefits of the digital machine factory? Reach out to us, and we'll gladly provide you with more information.

- Teamcenter

Teamcenter X: PLM Access Anywhere with Cloud Software-as-a-Service

Are you looking for future-ready PLM software that ensures access to the right documentation from any location? Companies face ongoing challenges to reduce costs, enhance productivity, and elevate quality. At the same time, these organisations need to adapt to changes in the market. Teamcenter X is a cloud Software-as-a-Service (SaaS) that provides direct access to preconfigured PLM capabilities with a simple user experience. Active Workspace is the primary user interface of Teamcenter X and enables users working from home, the office or anywhere else to securely access product information over the internet and easily collaborate on processes across the entire company. Tailoring to user needs Active Workspace is easy to customise to specific user needs. Teamcenter X can be hosted in the MCAD and ECAD design tool such as Siemens NX for your design teams or a simple web interface for all other users. Future-proof solution This cloud software provides a future-proof, modern cloud PLM solution that eliminates technical barriers. Teamcenter X enables you to work smarter with the latest technology and cloud microservices. Digital Twin Teamcenter X supports the full digital twin: create one parts list across multiple domains by managing, sharing and collaborating across multiple mechanical and electronic design tools. Accelerate product development time by reusing designs, managing changes and reducing lead time. Operating costs vs capital costs The flexible SaaS financial model includes installation, administration, operational management services and upgrades to help you get up and running quickly and cost effectively for a rapid return on your investment. Invest in the predictable use of operational costs of existing IT infrastructure versus capital costs for low ownership costs. External management Emixa industry Solutions manage all operations and maintenance for Teamcenter X, including installation and upgrades to keep you up-to-date with the latest product enhancements. This streamlined approach eliminates the complexities, costs, time investments, and risks associated with performing PLM installation, maintenance, and upgrades. Security and privacy The Siemens managed SaaS environment is built on enterprise-grade cloud infrastructure incorporating security, compliance and support for global organisations. The cloud infrastructure is housed in data centres designed to meet the requirements of the most security-sensitive companies. The cloud infrastructure safeguards privacy and mitigates the risk of data loss. Plug & Play PLM software With built-in configurations and best practices, Teamcenter X can help you get started quickly with managing your product lifecycle: MCAD data management ECAD data management Multi-CAD collaboration BOM management CAD-neutral JT visualisation Manage Microsoft Office documents Manage Adobe PDF files Manage all file types (TXT, GIF, MSG, HTML, etc.) Microsoft Office integration Active workspace Discover the Teamcenter X cloud PLM software today! Request the free 30-day trial and explore the world's most widely used PLM software through a full licence with sample files and guided tutorials. See and experience how your entire organisation can work smarter and faster!