Get Started with NX CAM Today.

RATED THE #1 CAM Software

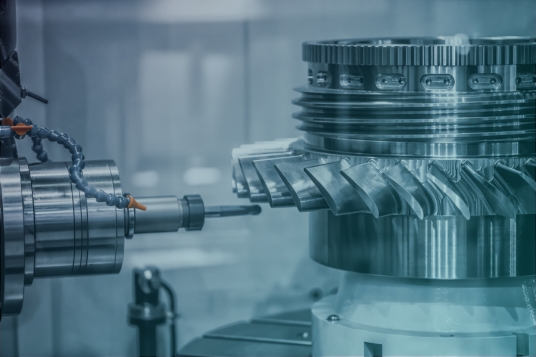

Siemens NX CAM is the world leading integrated NC programming solution providing all your programming requirements within a single solution. From 2.5-axis wire frame to complex simultaneous 5-axis milling or advances multi spindle mill/turn, NX CAM has the toolpaths and functionality to get the job done.

/Monier-Group-Logo-White.svg.png)

/Cerca-Magnetics-Logo-White.png)

/Sunseeker-Logo-White.png)

/JCB-Logo-White.png)

/RML-Group-Logo-White.png)

/XTRAC-Logo-White.png)

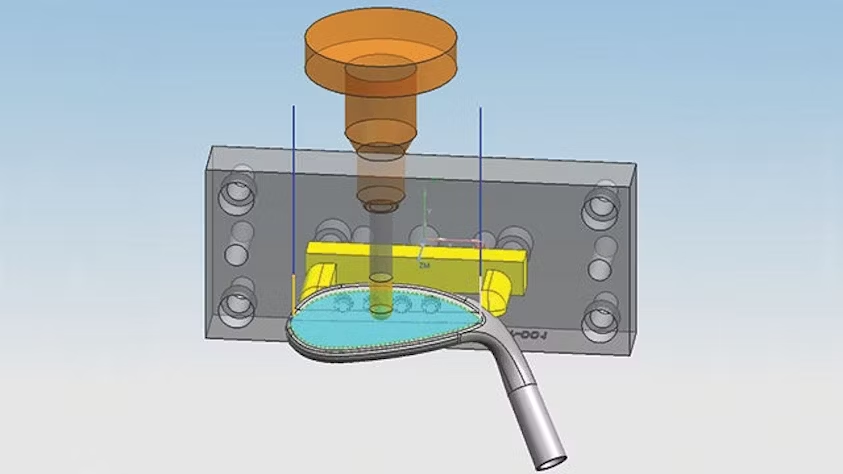

NX CAM enables you to efficiently generate toolpaths, simulate machining processes, and produce ready-to-run CNC programs for a wide range of machines. With built-in CAD capabilities, seamlessly prepare part models and define machine setups in one environment.

Key features include automated programming, advanced machining strategies, a cloud-connected tool library, integrated simulation, cloud-based postprocessing, and full integration with Siemens’ digital manufacturing solutions. Accelerate production, improve precision, and streamline the entire workflow, making it one of the most powerful and flexible CAM solutions available.

Programme, model, and link various production processes, such as CNC machining, robots, 3D printing, and quality control procedures. NX X Manufacturing is a cloud-powered software-as-a-service (SaaS) solution that will empower your workforce.

The Copilot function for NX X leverages generative AI to provide intelligent manufacturing suggestions, intuitive software guidance, and expert domain insights. It streamlines navigation and boosts productivity by quickly delivering answers.

NX CAM offers a single, integrated solution that tackles issues of designing, optimising and constructing metal and plastic components utilising the most recent additive manufacturing techniques.

Back in 2005, LimaCorporate took a bold step by exploring 3D printing for mass production of orthopaedic implants—despite the financial risks. That forward-thinking mindset has helped LimaCorporate become a pioneer in cementless implants, with Siemens Software playing a key role in their innovation journey.

Enhance your NX X Manufacturing system with Value Based Licensing and 20+ add-ons tailored to your project needs, from part preparation and productivity to specialised machining, simulation, postprocessors, and machine kits.

We're always adding new features to expand your capabilities. Value Based Licensing makes these add-ons easily accessible by adding new modules to the token pool.

RATED THE #1 CAM Software

Teamcenter Share for NX CAM simplifies collaboration with a connected, cloud-based platform. It offers secure file sharing, task management, desktop sync, and browser access, ensuring teams work from a single source of truth.

With design markups, version control, and smooth updates to machining, it accelerates development and improves quality. It’s a powerful tool for enabling seamless, flexible collaboration and driving digital transformation.

"Great examples, great trainer. Would highly recommend to anyone interested in learning NX CAM."

"Learned a lot completing the course and would recommend to anyone looking to learn NX CAM."

With a broad range of in-house expertise, Armo stands out as a trusted partner for solving complex challenges and delivering reliable, efficient solutions.

"Siemens Digital Industries Software lets us design at a much more precise level, which helps us communicate that precision with our suppliers more accurately."

Together we build the foundation of your business growth using Siemens NX CAM.

NX CAM is a sophisticated computer-aided manufacturing (CAM) software created by Siemens. It provides advanced functionalities for programming CNC machines, facilitating the efficient and precise production of intricate components. By seamlessly integrating design and manufacturing operations, NX CAM contributes to reduced production times, fewer errors, and improved overall productivity.

NX CAM accommodates a broad array of machining operations, including milling, turning, drilling, and multi-axis machining. This flexibility empowers manufacturers to manage various tasks within one cohesive platform, streamlining operations and eliminating the need for multiple software solutions.

Indeed, NX CAM is engineered to be compatible with various CNC machines. It produces machine-specific G-code through its post-processing capabilities, ensuring accurate execution of machining tasks across diverse equipment.

Yes, NX CAM features simulation tools that allow users to visualize and validate machining processes before implementation on the shop floor. This functionality aids in identifying potential challenges, minimizing errors, and optimizing tool paths, resulting in more efficient and reliable production cycles.

Certainly, NX CAM includes features for both high-speed machining and multi-axis machining. These capabilities facilitate the effective production of complex geometries and enhance surface finishes, meeting the requirements of contemporary manufacturing sectors.

You can buy NX CAM by reaching out to us directly, either through filling out the form on this page, emailing us or calling us. We are here to support you in exploring licensing options, arranging a personalised demonstration, or accessing a trial version, allowing your team to engage with NX CAM directly. Additionally, we provide training and support to ensure a seamless implementation.

NX CAM is a sophisticated computer-aided manufacturing (CAM) software created by Siemens. It provides advanced functionalities for programming CNC machines, facilitating the efficient and precise production of intricate components. By seamlessly integrating design and manufacturing operations, NX CAM contributes to reduced production times, fewer errors, and improved overall productivity.

NX CAM accommodates a broad array of machining operations, including milling, turning, drilling, and multi-axis machining. This flexibility empowers manufacturers to manage various tasks within one cohesive platform, streamlining operations and eliminating the need for multiple software solutions.

Indeed, NX CAM is engineered to be compatible with various CNC machines. It produces machine-specific G-code through its post-processing capabilities, ensuring accurate execution of machining tasks across diverse equipment.

Yes, NX CAM features simulation tools that allow users to visualize and validate machining processes before implementation on the shop floor. This functionality aids in identifying potential challenges, minimizing errors, and optimizing tool paths, resulting in more efficient and reliable production cycles.

Certainly, NX CAM includes features for both high-speed machining and multi-axis machining. These capabilities facilitate the effective production of complex geometries and enhance surface finishes, meeting the requirements of contemporary manufacturing sectors.

You can buy NX CAM by reaching out to us directly, either through filling out the form on this page, emailing us or calling us. We are here to support you in exploring licensing options, arranging a personalised demonstration, or accessing a trial version, allowing your team to engage with NX CAM directly. Additionally, we provide training and support to ensure a seamless implementation.