Start your free Tecnomatix Process Simulate trial

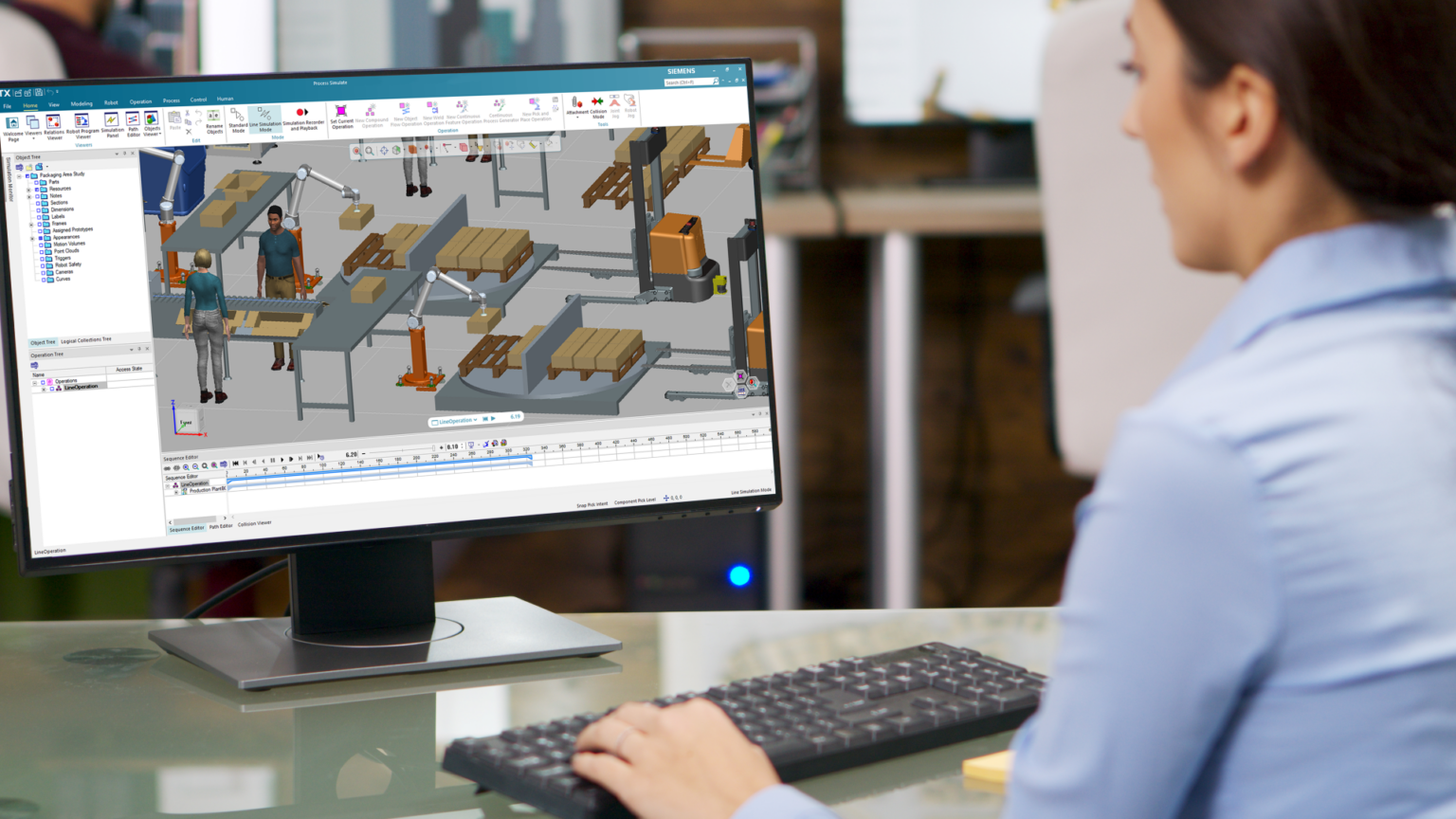

Plan, simulate & validate entire manufacturing operations before the physical environment is created.

Tecnomatix Process Simulate unites manufacturing and product engineering to help you plan, simulate, and validate operations before the physical setup exists. Simulate real-world production performance, from assembly lines and robotics to logistics and human interaction.

/Mr.Mallo-Logo-White.png)

/BD-Logo-White.png)

/P%26G-Logo-White.png)

/DAF-Logo-White.png)

Manufacturers face growing challenges that demand a rethink of traditional methods. Multi-site operations, supply chain issues & rising demand for customised, sustainable products can strain capacity.

Effective planning and advanced production optimisation are key to staying ahead. We present two modern solutions:

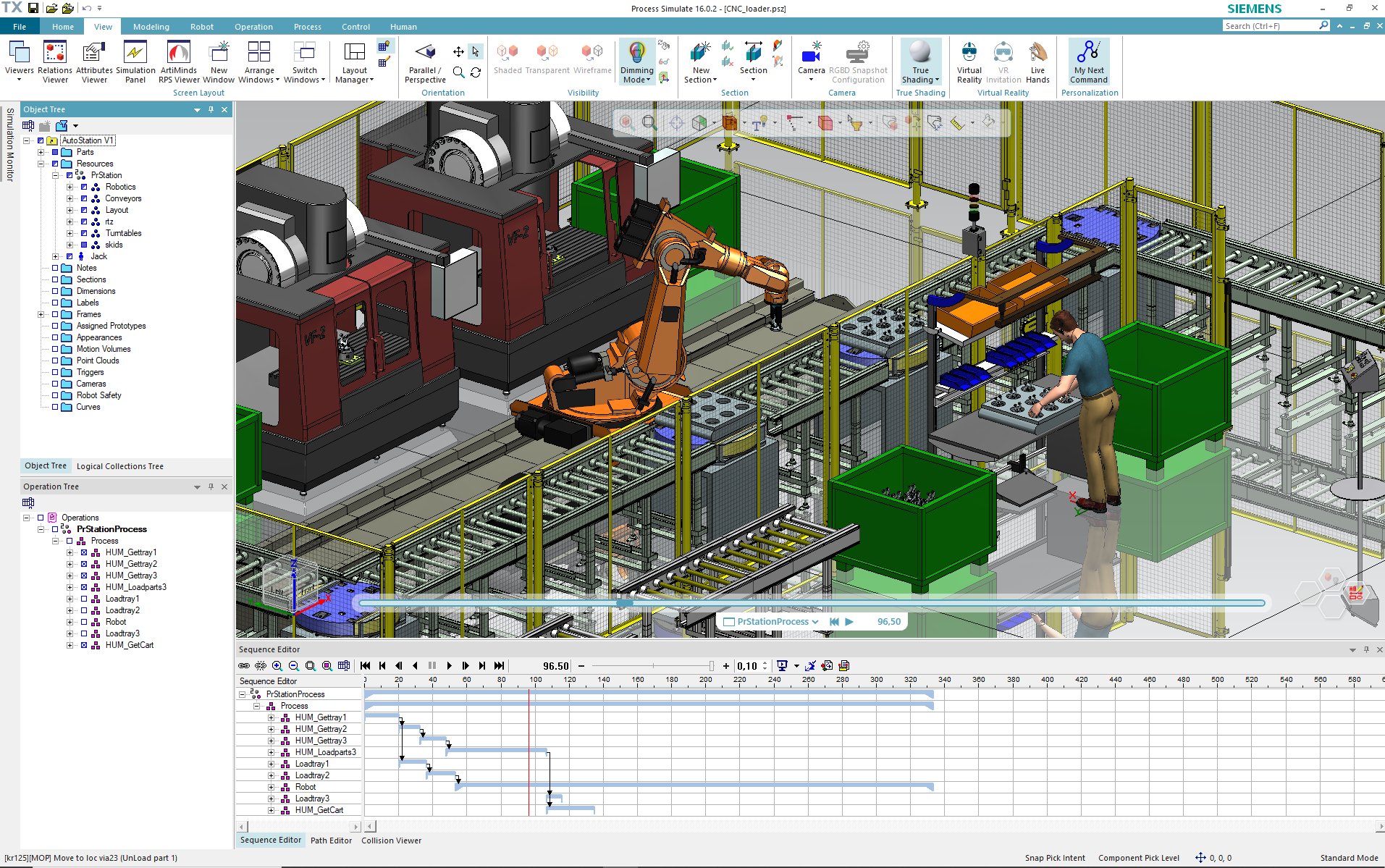

Process Simulate X is a powerful cloud-based SaaS solution for digital manufacturing, enabling you to plan, simulate, and validate human tasks, robotic operations, and automation in a dynamic 3D environment. With the added advantages of cloud flexibility, enterprise-grade security, and scalable performance, it supports faster, smarter production planning and optimisation.

Core capabilities include discrete and continuous manufacturing, 3D factory design, assembly simulation, and more, empowering manufacturers to streamline processes and accelerate time to market.

Engage in secure collaboration with Teamcenter Share for Process Simulate, a cloud-based application. It offers a centralised data repository, ensuring access to the correct versions and facilitating effective task management. Leverage this robust tool to enhance the quality of manufacturing planning and the development of production systems.

Discover how Tecnomatix Process Simulate Virtual Reality empowers manufacturers to gain a competitive advantage by streamlining the product introduction process. By transforming planning and minimizing the reliance on physical prototypes, this innovative tool greatly enhances operational efficiency.

The capabilities encompass the design, analysis, and optimisation of intricate human operations by scaling virtual human figures to represent any worker population for task simulations. The necessity for physical validations is significantly decreased as VR technology enables users to engage deeply with the 3D plan, facilitating real-time problem-solving within the virtual realm.

Plan, simulate & validate entire manufacturing operations before the physical environment is created.

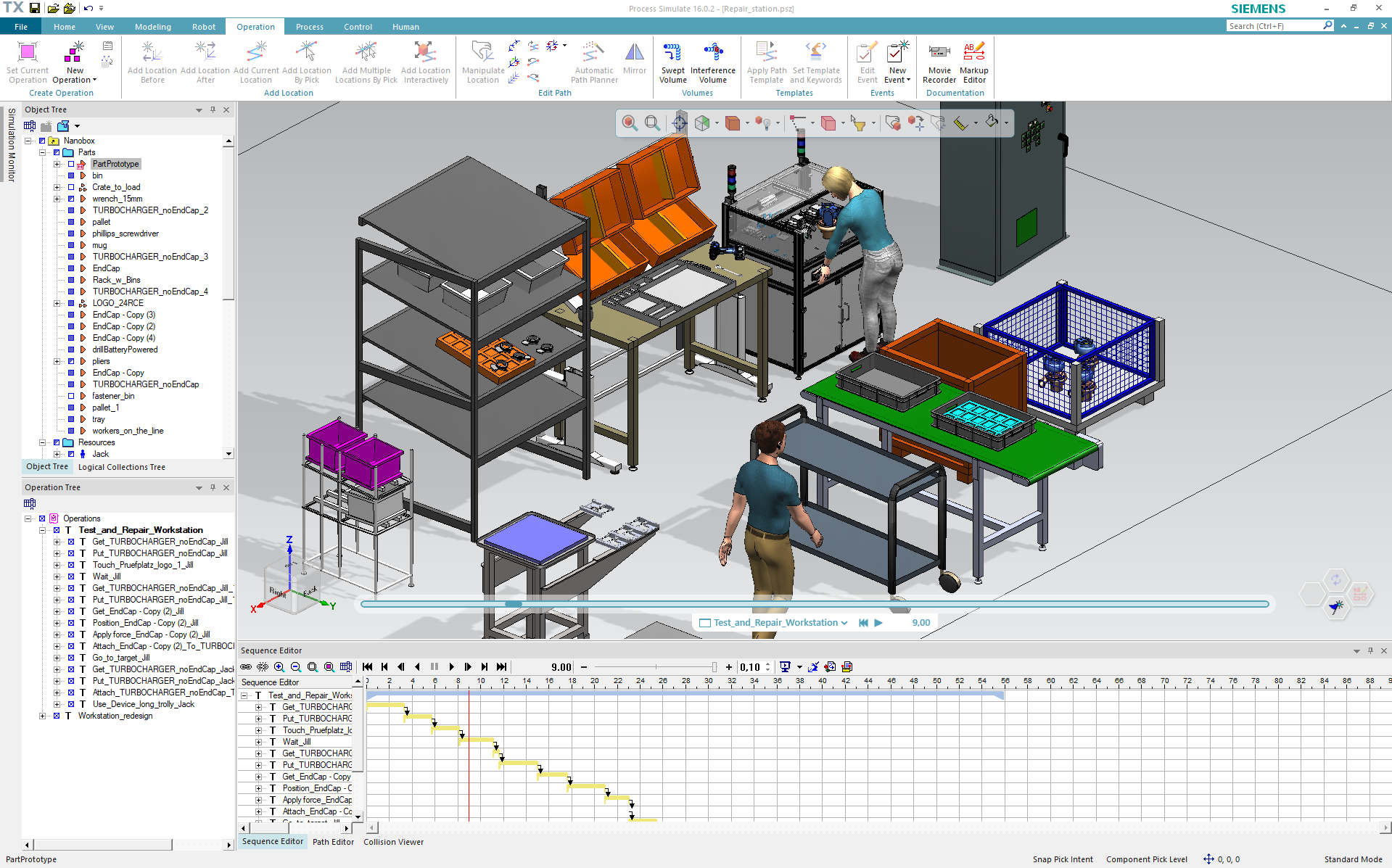

Create, evaluate, and confirm product assembly and disassembly procedures to identify the fastest, most effective, and collision-free sequence.

To model, create and simulate dynamic assembly and disassembly pathways and operation sequences, identify collisions and evaluate clearance, and perform 2D and 3D sectioning and measurement studies, use Process Simulate. Choose the best tool for the job, do virtual clearance tests and collision analyses, and model the entire product and tool process together.

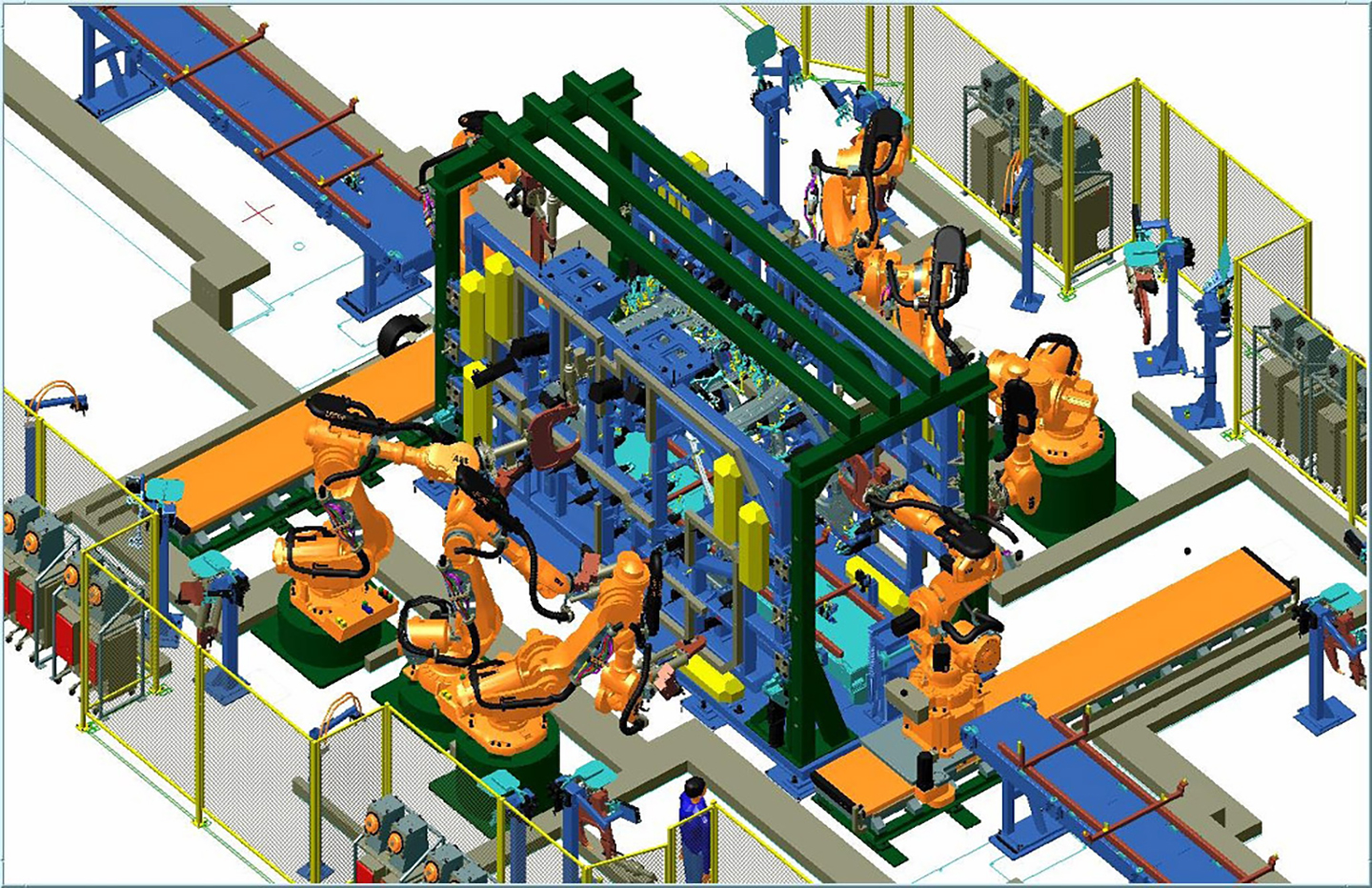

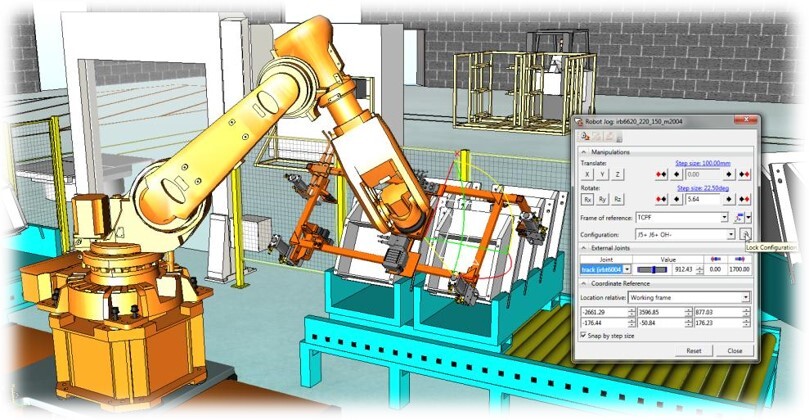

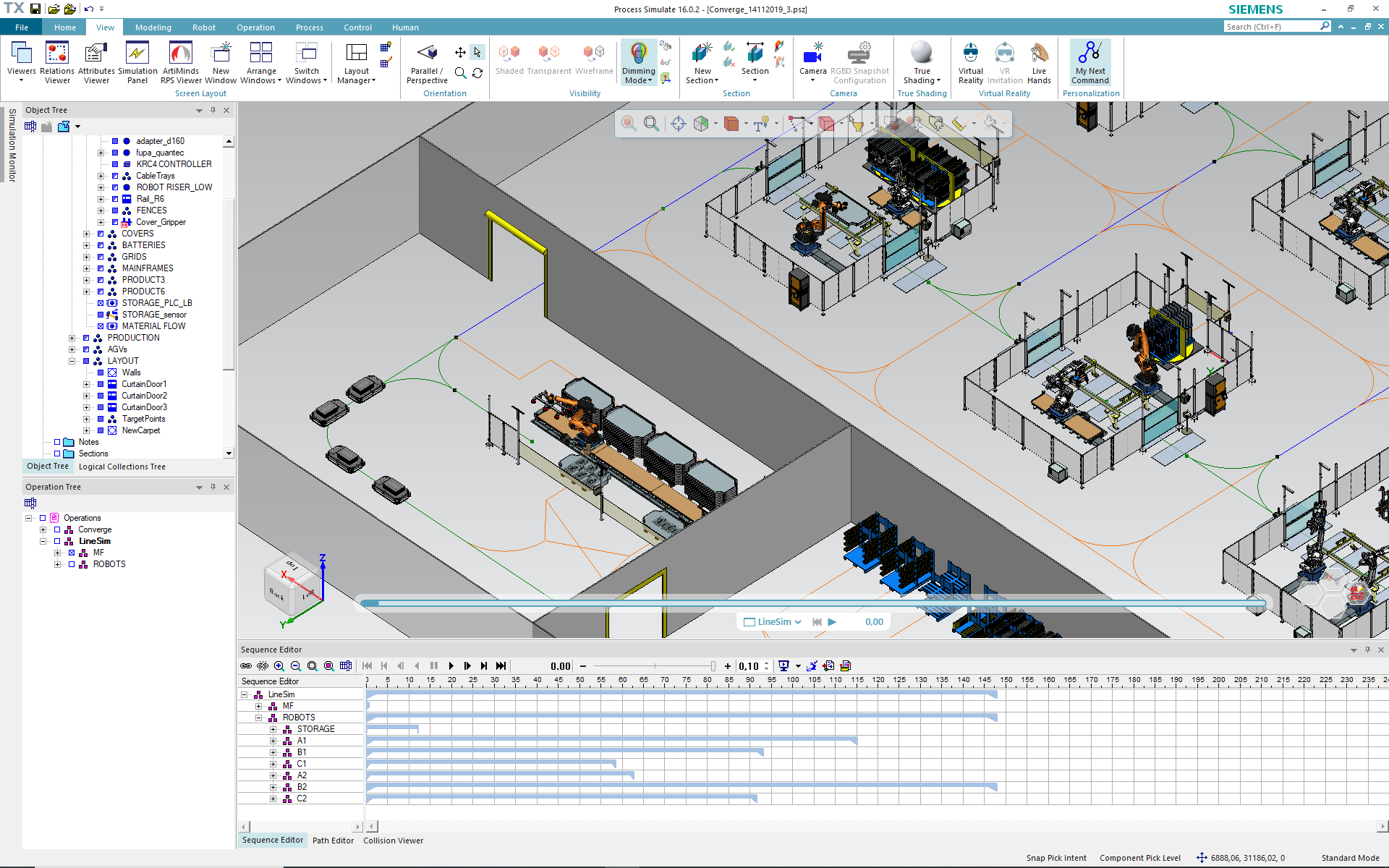

Engage in virtual development, simulation, and commissioning of robotic and automated manufacturing systems, encompassing highly automated facilities with diverse production mixes. Utilize Process Simulate robotics to enable collision-free planning of robot motion paths and simulations, facilitate automatic robot placement and reach testing, and optimise robotic operation cycle times and energy consumption.

This software also streamlines the synchronisation process for multi-robot workstations and operational zones. It’s designed to support various engineering disciplines in planning and validating manufacturing systems, from individual workstations to comprehensive production lines.

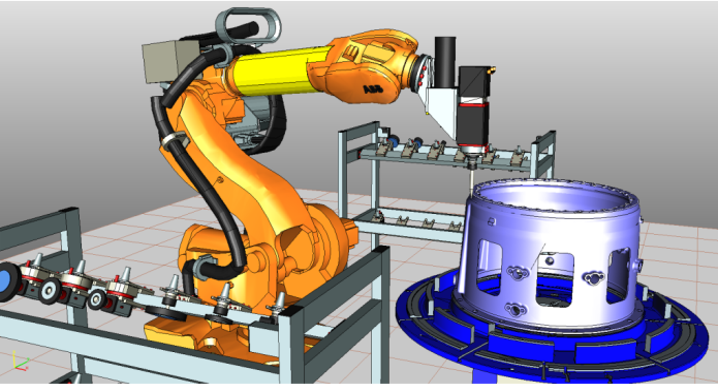

Enhance and fine-tune robotic operations in a dynamic 3D virtual environment, ensuring that ongoing production remains uninterrupted. Employ Process Simulate offline programming to establish and modify robot-specific target locations, orientations, configurations, motion paths, and interference zones.

Conduct cycle time optimisation, create and edit configurable motions and OLP commands, perform robot calibration, and manage complete robot programme downloads and uploads using the robot teach pendant interface and controller for all leading robot brands.

Execute virtual commissioning using offline Process Simulate models, which includes creating layouts, defining kinematics, and conducting simulations and analyses. Utilise Process Simulate commissioning to validate and optimize the construction, installation, and commissioning (both mechanical and electrical) of manufacturing zones or cells that incorporate robots and other automation devices.

Simulate actual programmable logic controller (PLC) code alongside the hardware using Siemens TIA Portal and PLCSIM Advanced software, as well as OPC UA software and genuine robot programs, to create the most realistic virtual commissioning environment.

Design, analyse, and optimize intricate human operations by adjusting virtual human figures to accommodate any worker population for various task simulations. Implement Process Simulate human simulation to validate workstation designs, ensuring accessibility for product parts during assembly and maintenance.

Analyse and improve cycle times and ergonomics of human operations and workstations, guaranteeing a safe process in alignment with industry and corporate standards.

Create robotic manufacturing processes utilising tools for weld seam development and continuous path generation for gluing, sealing, and spraying operations, along with comprehensive robot motion path simulation and optimization regarding robot placement, reach, and cycle time.

Leverage Process Simulate continuous manufacturing to import weld seams and machining toolpaths, generate weld seams and continuous motion paths based on curve and geometry recognition, align path locations according to surface-normal conditions, and simulate paint and spray coverage and thickness.

Using its world-class knowledge in motion, industry-leading quality and expertise in manufacturing and cost control, Estun provides customers with the competitive advantage to succeed.

Serving industries such as automotive, aerospace, electronics and industrial manufacturing, the firm has built a reputation for delivering high-performance robotic systems tailored to complex production challenges. Their latest innovation, Wirebot, is transforming the complex process of wire harness assembly for electrical cabinets.

BenThor Automation’s core competencies include automation solutions for machines and production facilities. Its main focus is the automotive industry. The services provided by BenThor Automation include a complete process chain ranging from consulting, technical solutions, hardware planning and software development to device deployment and after-sales service.

Together we build the foundation of your business growth using Tecnomatix

Tecnomatix Process Simulate is an innovative digital manufacturing solution created by Siemens, enabling you to model, simulate, and validate manufacturing processes within a 3D environment. By generating virtual representations of your production systems, you can detect and address potential issues early on, optimise workflows, and minimise the necessity for physical prototypes, ultimately resulting in cost savings and enhanced efficiency.

Certainly. Tecnomatix Process Simulate provides comprehensive tools for simulating robotic operations and automated manufacturing systems. It facilitates collision-free robot motion path planning, automatic robot placement, reach testing, and cycle time optimisation, ensuring your robotic processes operate effectively and without conflicts.

Yes, Tecnomatix Process Simulate enables virtual commissioning by allowing you to validate and optimise the assembly, installation, and commissioning of manufacturing cells and lines equipped with robots and other automation devices. This capability aids in identifying and addressing issues before actual commissioning, thereby reducing downtime and costs related to physical commissioning.

Indeed, it does. Tecnomatix Process Simulate Human empowers you to design, analyse, and optimise intricate human operations by scaling virtual human figures to accommodate any worker population for task simulations. This ensures workstations are ergonomically designed, thus promoting worker safety and efficiency.

Tecnomatix Process Simulate is designed to seamlessly integrate with a variety of manufacturing systems and PLM solutions. It supports data interchange with CAD systems and can operate in conjunction with Siemens' Teamcenter, facilitating a cohesive workflow from design to production.

Tecnomatix Process Simulate is adaptable and can be applied across multiple industries, including automotive, aerospace, electronics, consumer goods, industrial machinery and many more. Any sector involved in complex manufacturing processes and aiming to optimise production efficiency can derive significant benefits from utilising this simulation tool.

You can buy Tecnomatix Process Simulate by reaching out to us directly, either through filling out the form on this page, emailing us or calling us. We are here to support you in exploring licensing options, arranging a personalised demonstration, or accessing a trial version, allowing your team to engage with Tecnomatix Process Simulate directly. Additionally, we provide training and support to ensure a seamless implementation.

![Bijlage 2 - Digital Maturity How to Turn Your Digital Strategy into Reality[100].jpg](https://www.emixa.com/hubfs/Bijlage%202%20-%20Digital%20Maturity%20How%20to%20Turn%20Your%20Digital%20Strategy%20into%20Reality%5B100%5D.jpg.png)

Tecnomatix Process Simulate is an innovative digital manufacturing solution created by Siemens, enabling you to model, simulate, and validate manufacturing processes within a 3D environment. By generating virtual representations of your production systems, you can detect and address potential issues early on, optimise workflows, and minimise the necessity for physical prototypes, ultimately resulting in cost savings and enhanced efficiency.

Certainly. Tecnomatix Process Simulate provides comprehensive tools for simulating robotic operations and automated manufacturing systems. It facilitates collision-free robot motion path planning, automatic robot placement, reach testing, and cycle time optimisation, ensuring your robotic processes operate effectively and without conflicts.

Yes, Tecnomatix Process Simulate enables virtual commissioning by allowing you to validate and optimise the assembly, installation, and commissioning of manufacturing cells and lines equipped with robots and other automation devices. This capability aids in identifying and addressing issues before actual commissioning, thereby reducing downtime and costs related to physical commissioning.

Indeed, it does. Tecnomatix Process Simulate Human empowers you to design, analyse, and optimise intricate human operations by scaling virtual human figures to accommodate any worker population for task simulations. This ensures workstations are ergonomically designed, thus promoting worker safety and efficiency.

Tecnomatix Process Simulate is designed to seamlessly integrate with a variety of manufacturing systems and PLM solutions. It supports data interchange with CAD systems and can operate in conjunction with Siemens' Teamcenter, facilitating a cohesive workflow from design to production.

Tecnomatix Process Simulate is adaptable and can be applied across multiple industries, including automotive, aerospace, electronics, consumer goods, industrial machinery and many more. Any sector involved in complex manufacturing processes and aiming to optimise production efficiency can derive significant benefits from utilising this simulation tool.

You can buy Tecnomatix Process Simulate by reaching out to us directly, either through filling out the form on this page, emailing us or calling us. We are here to support you in exploring licensing options, arranging a personalised demonstration, or accessing a trial version, allowing your team to engage with Tecnomatix Process Simulate directly. Additionally, we provide training and support to ensure a seamless implementation.