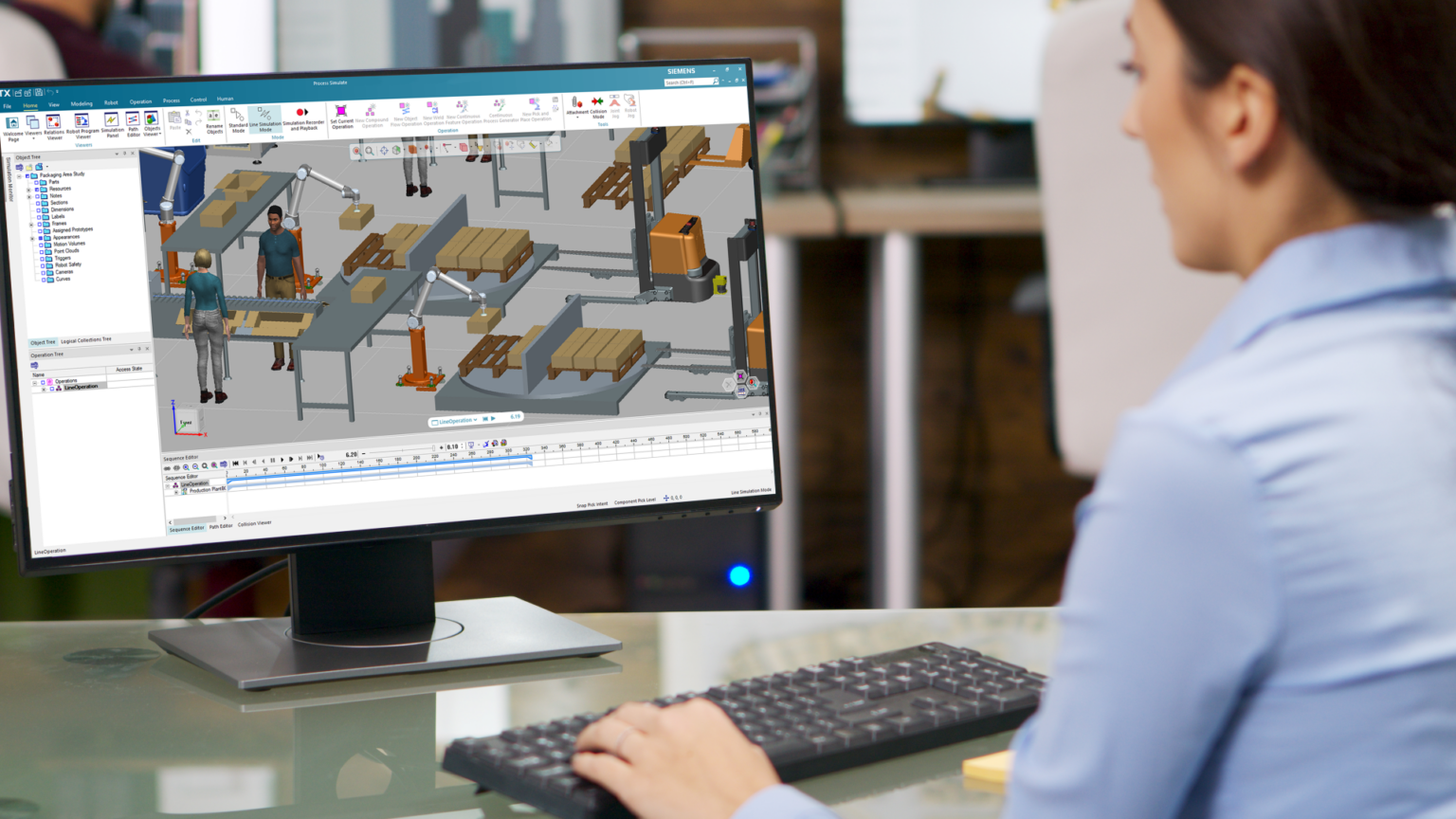

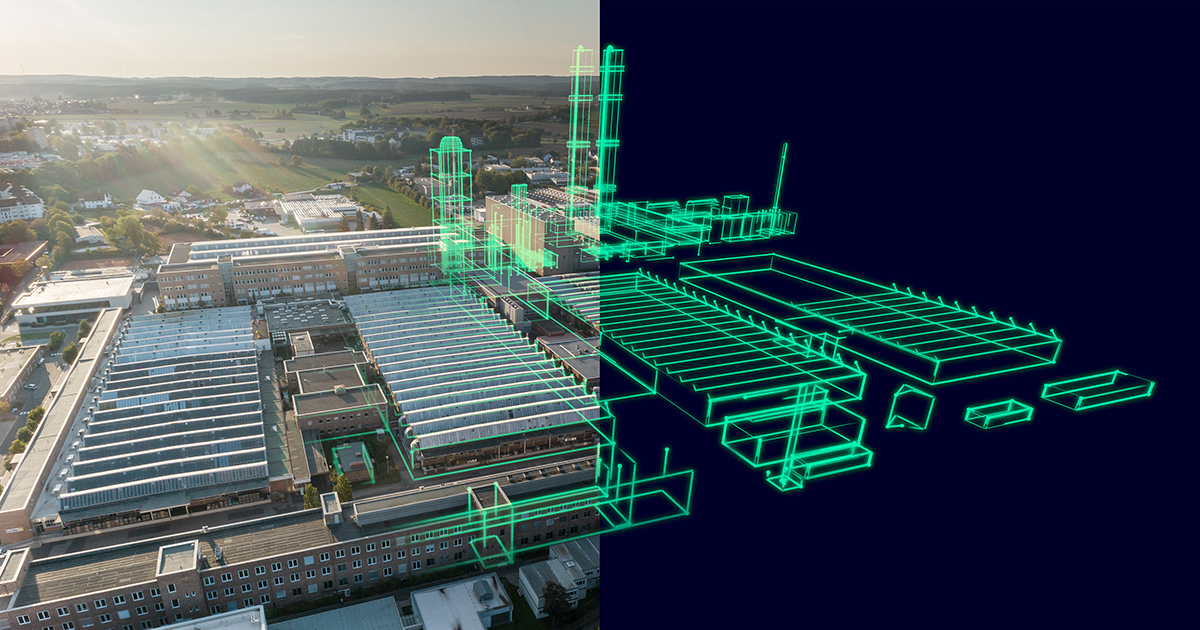

Siemens Process Simulate X enhances the planning, simulation, and validation of robotic processes with integrated support for Stäubli robots. Built on cloud technology, Process Simulate X enables seamless validation of robotics, human tasks, and automation across the entire product development lifecycle, from concept and engineering to commissioning, production, and continuous improvement.

Stäubli Robotics portfolio includes industrial robots, collaborative robots (cobots), and application-specific systems designed to handle complex operations with exceptional precision and efficiency.

/ASML-Logo-White.png)

/DAF-Logo-White.png)

/Kornelis-Logo-White.png)

/Mr.Mallo-Logo-White.png)

/P%26G-Logo-White.png)

/UPS-Logo-White.png)