Start your 30-Day Simcenter 3D Free Trial Today

World’s Leading Engineering Simulation Platform

Simcenter Free Trial – Access in 60 seconds. Enter your details & click Get Started Now ➤➤➤

Millions of Engineers use Simcenter, good choice!

Siemens Simcenter CAE Software: An advanced & powerful CAE environment – simulation & analysis is fast & easy. Unlock geometry editing capabilities, associative simulation modeling & multi-discipline solutions.

/John-Deere-Logo-White.png)

/Collins-%20Aerospace-%20Logo-White.png)

/COX-Marine-Logo-White.png)

/Cercacor-Logo-White.png)

/Brabant%20Engineering-Logo-White.png)

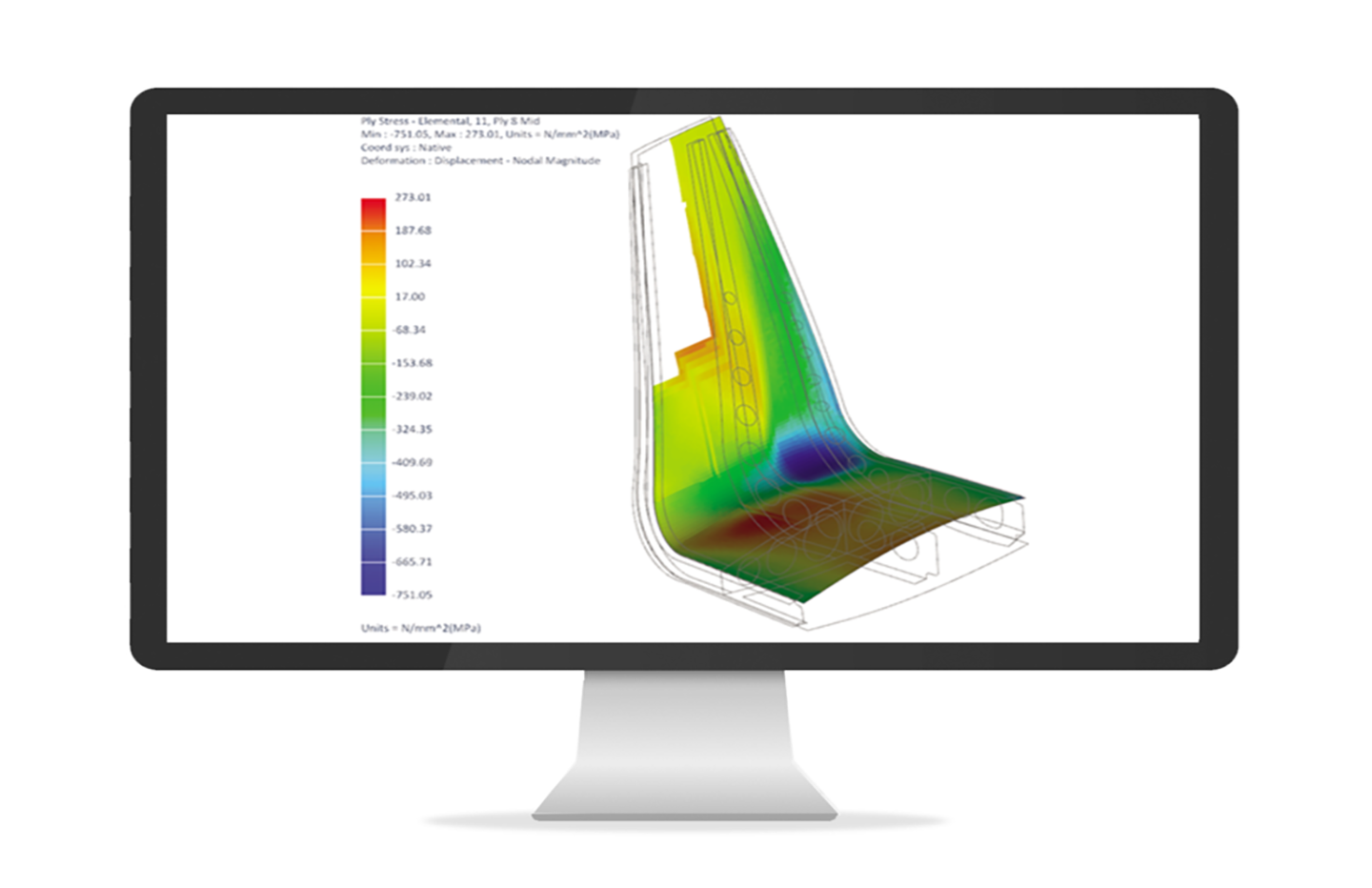

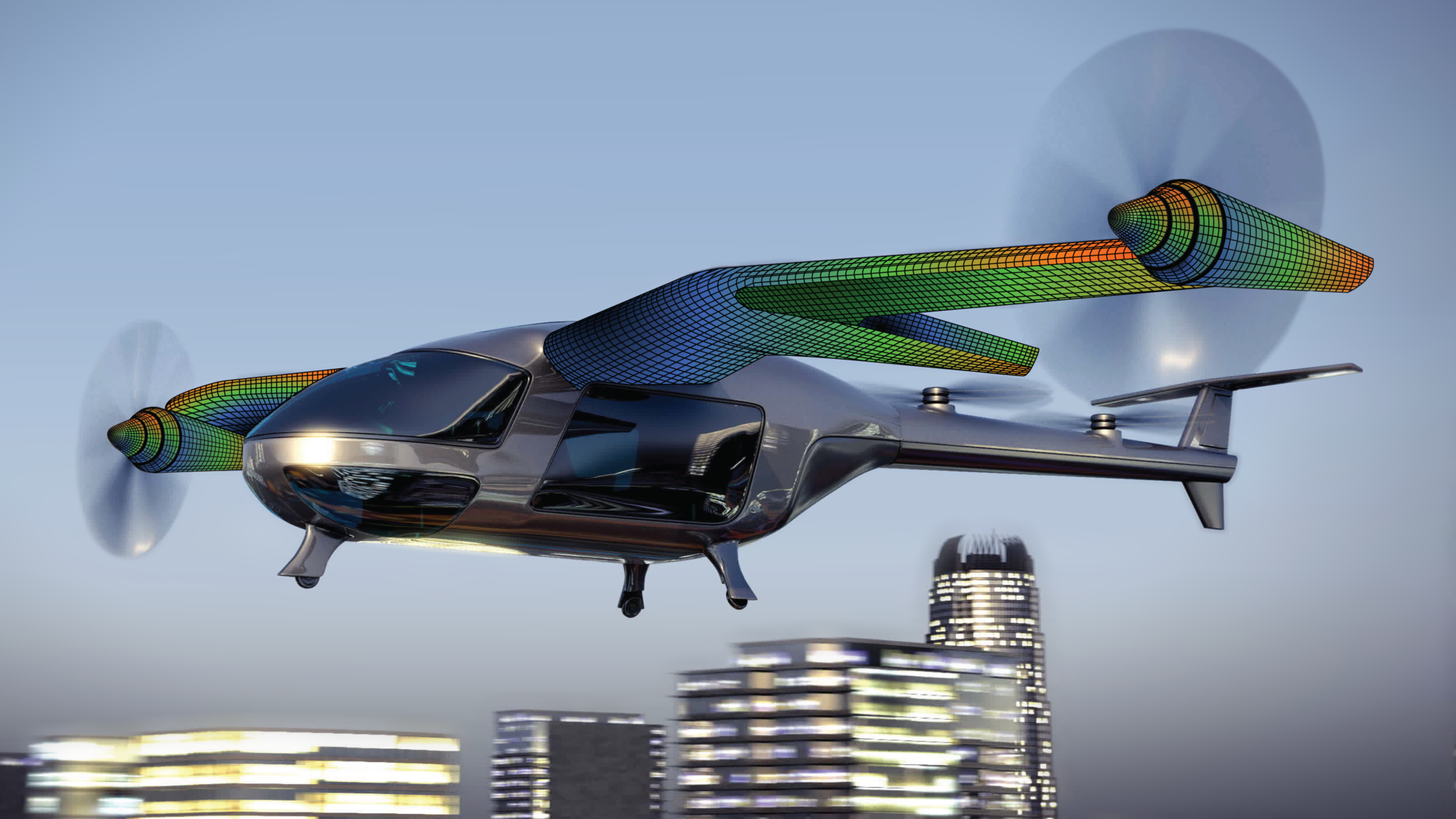

Simcenter 3D includes dedicated tools for efficient modeling of laminar composite structures, using zone-based (on the mesh) and ply-based (on faces and/or 2D elements) modeling techniques, or a combination of both.

You can keep your model up-to-date with the latest design through associativity with the geometric model. Simcenter 3D can communicate with the Fibersim portfolio of software for composites engineering, facilitating a tight collaboration between analysis teams and composite designers.

Simulation results and data can be shared and transferred to other Simcenter 3D applications. This provides an open and flexible environment and a complete overview of the product. Simcenter 3D takes into consideration a vast range of risks and challenges that may harm the effectiveness and validity of a product, giving the engineer complete confidence in their work.

Simcenter 3D helps you work faster by instantly updating simulation results when design changes are made. Its powerful tools simplify geometry editing, mesh creation, and model setup, making it easy to go from CAD to full analysis. With automated processes and support for multiple solvers, you save time and speed up development.

World’s Leading Engineering Simulation Platform

Simcenter Free Trial – Access in 60 seconds. Enter your details & click Get Started Now ➤➤➤

Millions of Engineers use Simcenter, good choice!

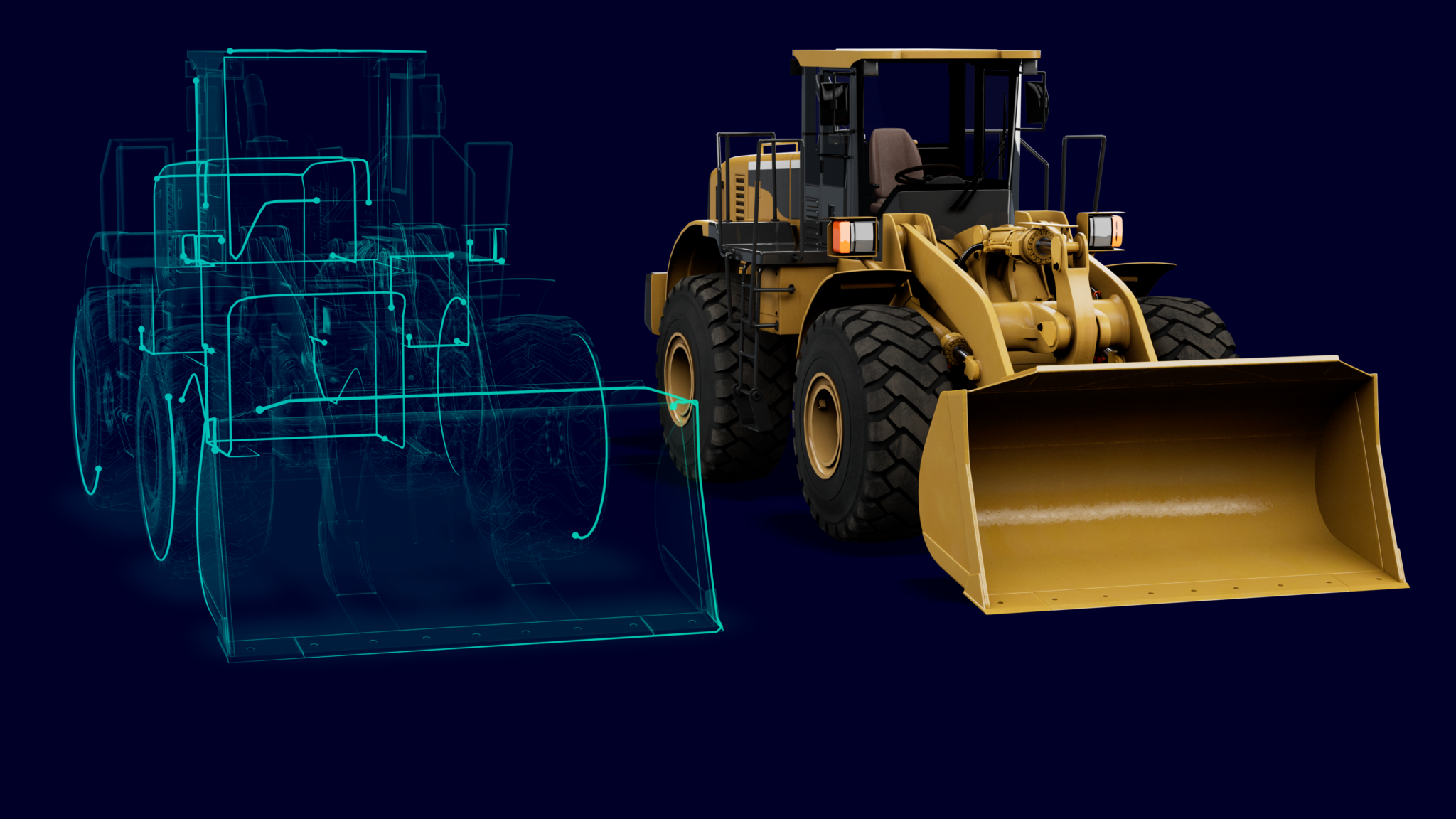

Integrate mechanical, electrical, and software systems, use new materials and methods, and shorten design cycles—all at once.A Digital Twin approach enables a more predictive, systems-driven development process.

Predict performance earlier in the development cycle and across the full product lifecycle with Simcenter’s combination of system simulation, 3D CAE, and physical testing all in one environment.

Optimize designs, reduce risks, and bring innovations to market faster using Simcenter’s blend of physics-based simulation with data-driven insights.

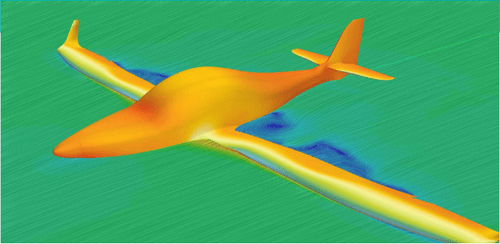

To bring fully electric, FAA-certified aircraft to market, Bye Aerospace turned to Siemens Xcelerator to unify design, simulation, and data management. Using tools like NX, Fibersim, and Simcenter, the team accelerated development cycles, reduced staffing needs by two-thirds, and delivered a low-noise, zero-emission aircraft — proving that electric aviation is not just possible, but practical.

As tractors became faster and more advanced, cab noise at high speeds emerged as a major issue. John Deere partnered with Simcenter Engineering and used advanced acoustic simulation to pinpoint and resolve the root causes early in development. This allowed their teams to design quieter, more comfortable operator environments — enhancing productivity for farmers worldwide.

To engineer a new class of high-performance diesel outboard engines, Cox Marine implemented Siemens’ Teamcenter, NX, and Simcenter software. The result: a cleaner, more fuel-efficient engine built on a digital twin, supported by scalable, integrated systems. By using simulation early, they cut development time by months and positioned themselves to disrupt the global marine market.

Emixa stands at the forefront of digital transformation, offering innovative and comprehensive solutions tailored to the manufacturing sector. Our expertise spans across Siemens PLM, SAP ERP, and Mendix Low Code Applications, enhanced by our strengths in Management Consulting, Integration Solutions, and Data & Analytics.

Simcenter can transform your product simulation process. Get started today.

Simcenter simulation and testing solutions help engineering departments simulate, optimize and verify critical performance aspects of complex products.

Simcenter 3D is available as a stand-alone simulation environment. The solution is fully integrated into NX and provides a seamless CAD/CAE experience.

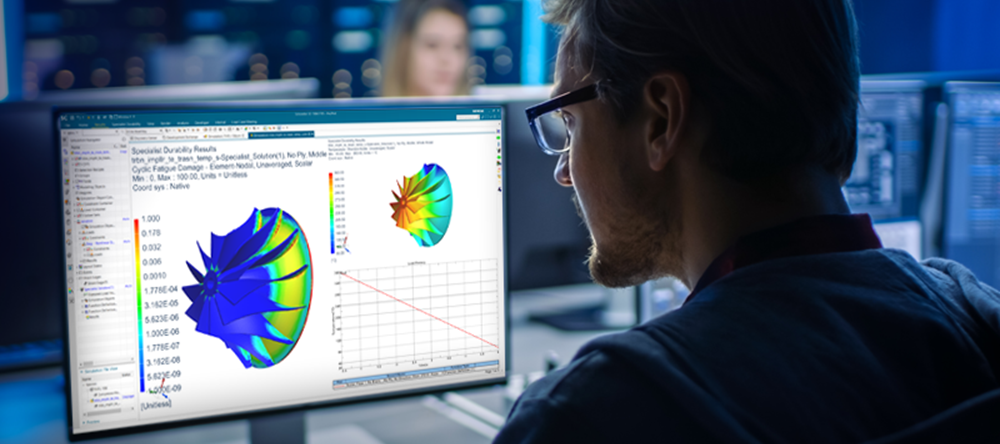

Simcenter 3D Durability can be used to determine rotor base fatigue life in large rotating machines. Medicine Durability and full function is especially important for medical devices. Simcenter 3D Specialist Durability is used to avoid failures of citical systems.

Simcenter simulation and testing solutions help engineering departments simulate, optimize and verify critical performance aspects of complex products.

Simcenter 3D is available as a stand-alone simulation environment. The solution is fully integrated into NX and provides a seamless CAD/CAE experience.

Simcenter 3D Durability can be used to determine rotor base fatigue life in large rotating machines. Medicine Durability and full function is especially important for medical devices. Simcenter 3D Specialist Durability is used to avoid failures of citical systems.