- PLM

Reap all the Benefits of Additive Manufacturing

Companies are challenged every day by their customers with requests for more complex products, in smaller batches, with shorter lead times and at lower prices. An almost impossible ask, but if your competitor can deliver, you can't fall behind.

Innovative technologies like Additive Manufacturing (AM) can improve and streamline your processes. When used correctly, AM offers numerous advantages over conventional production technologies. It brings about a revolutionary shift in the way we manufacture parts across various industries, catering not only to big businesses but also to small and medium enterprises.

Additive Manufacturing in the product lifecycle

Additive Manufacturing, also called 3D printing, has existed for over 35 years. But considering we've used conventional tech like subtractive and forming processes for thousands of years, you could say we've only just begun tapping into AM's potential. Starting in the '80s as a rapid prototyping tech, it's now increasingly used across the product lifecycle.

Diverse applications need different materials and processes. Luckily nowadays there are printers that easily switch materials, vastly expanding possibilities. With professional, affordable desktop 3D printers you can print most of your prototyping and tooling applications quickly, cheaply and in-house. For some applications, it's even possible to print end-use parts or spares.

Prototype

3D print your visual and functional prototypes to detect issues earlier, test new features and cut down time-to-market.

Tooling

Through the printing of production tooling, the ability to craft custom tools becomes a faster, more cost-effective, and in-house possibility. But the real value lies in the impact these custom tools can have on your processes, making them more efficient, rapid and safe.

Production part

Using 3D printing as a production technology to manufacture end-use parts makes it possible to create components that would be impossible with conventional manufacturing methods.

Spare parts

By 3D printing your spare parts on-demand, you can reduce inventory, storage space, and waste. Combining this with on-site printing also lowers transportation and packaging costs.

Benefits of Siemens NX™ Additive Manufacturing

- Greater design freedom

- Customisation, enabling lot size 1

- Utilisation of only essential materials

- Part consolidation and function integration

- Enhanced performance

- Metamaterials

- Print "on-demand" and "on-location"

Industrial Additive Manufacturing

For advanced applications, industrial 3D printers are sometimes the best solution due to specific material needs, build volume, capacity or resolution. An increasing number of companies successfully print a wide range of apps across sectors. But AM isn't a standalone process - upstream and downstream procedures must be considered too.

Design for Additive Manufacturing (DFAM)

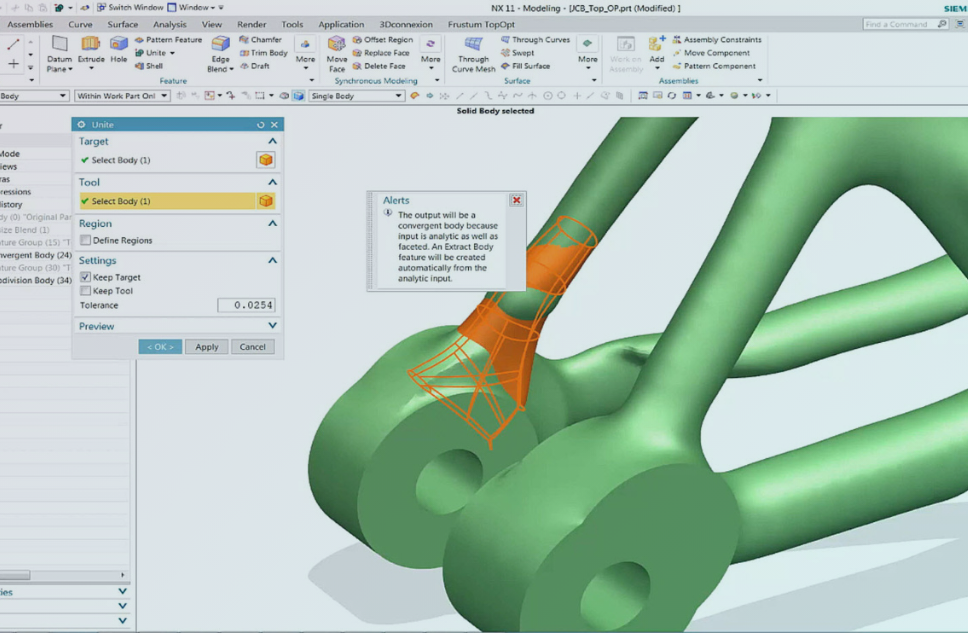

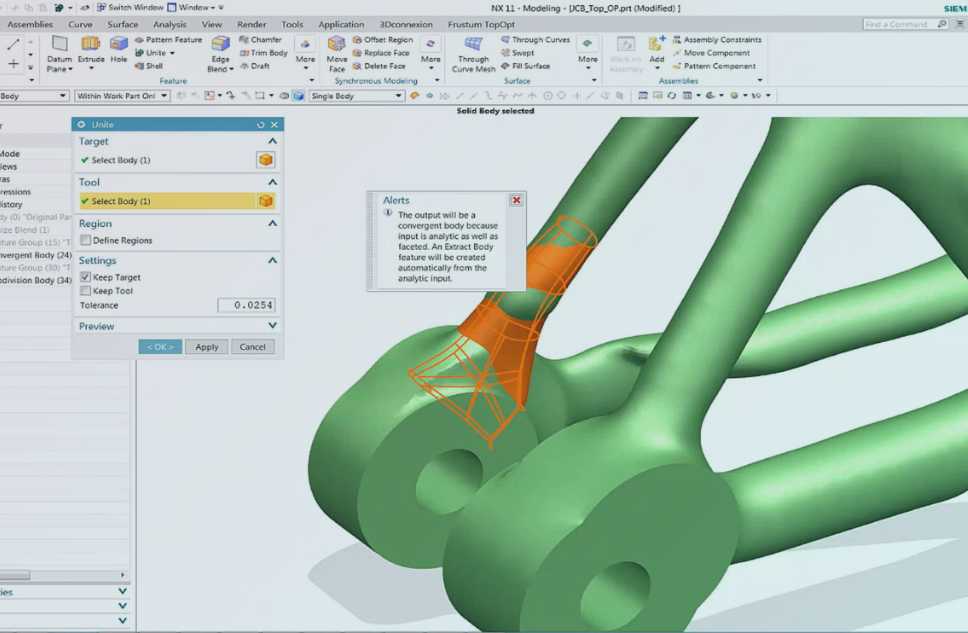

Every production process has design rules and tools. As "Additive" is the very opposite of conventional "subtractive" manufacturing, traditional design tools don't always give the needed results. You don't remove material from a block, only adding it where necessary. That's why Siemens NX developers have added new design capabilities in recent years, helping designers fully harness AM's potential.

AM Build Preparation & Simulation

In 3D printing, the orientation of a part in the printer plays a crucial role, affecting strength, quality, costs, print times, material usage, and post-processing. Siemens NX's Build Preparation functionality offers orientation guidance, allowing you to save the desired orientation directly in the CAD model, ensuring consistent and repeatable outcomes.

CNC Post-Processing

Once your metal print is complete, the removal of metal supports is still necessary. Manual removal can be labor-intensive and lacks repeatability. This process can be automated via CNC milling, automatically eliminating supports and ensuring correct dimensions and surface finish. Programming and simulating the milling process can also be done in Siemens NX, preventing collisions and milling issues.

Whether you're new or experienced in 3D printing, just exploring its potential or running industrial printers 24/7. We're here to support your business every step of the way to successfully implement Additive Manufacturing.

Author: Bart Stuve

Published date: August 26, 2025

Explore our Technology. Access our downloads center.

Access NowStart your Digital Transformation with Emixa

We help businesses transform their digital future with cutting-edge technology and strategic products & services