- PLM

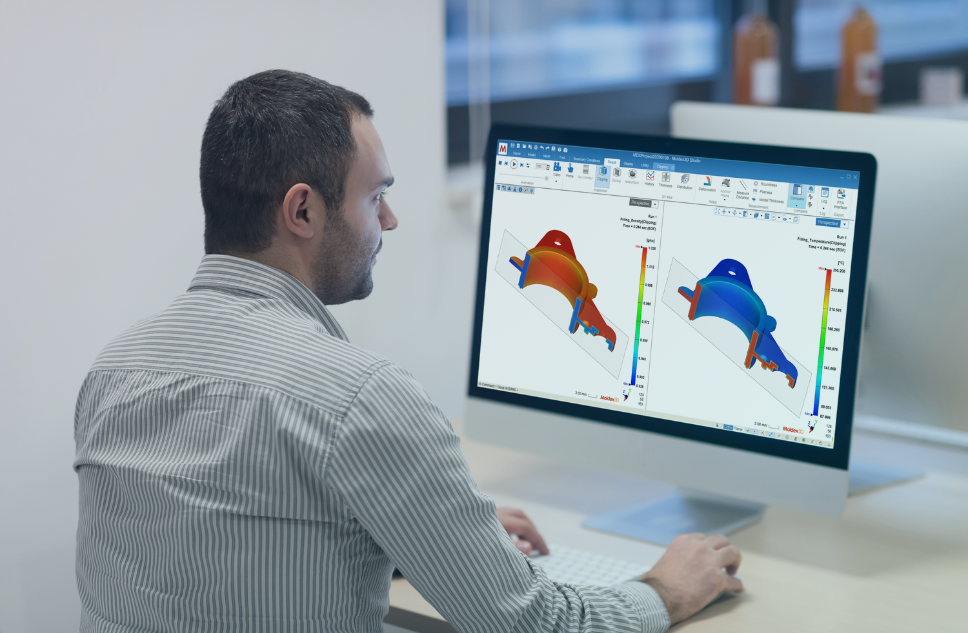

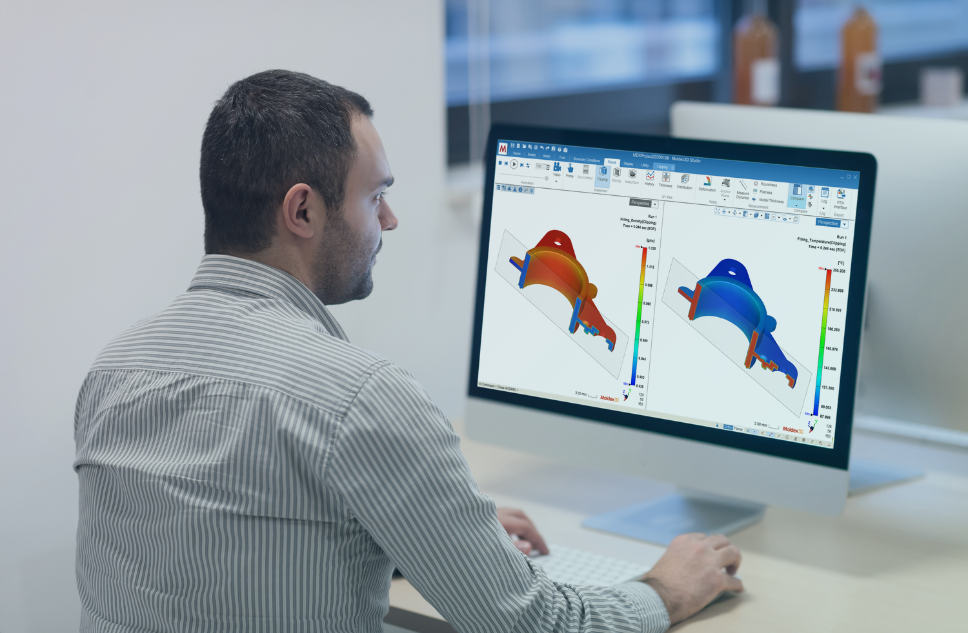

The Added Value of Moldex3D and Injection Moulding Analysis

Moldex3D is a software program developed to carry out accurate analyses and simulations of advanced plastic injection molding processes. This software enables you to optimise mold design, increase producibility and accelerate the time-to-market.

This software helps you to predict and remedy challenges, by analysing and identifying any potential problems in the injection molding process, including temperature, pressure or shrinkage. 85% of common production problems that occur can be predicted and solved in advance.

Injection molding simulation provides valuable insights into the design process, and future results in terms of production. This type of software offers major advantages in that it allows you to assess and qualify designs early, as well as being able to predict and remedy any risks in the product development process, prior to production. Most importantly, it saves time and reduces costs.

Identify problems at an early stage

In about 80% of cases, Moldex3D identifies design issues that will go undetected by standard DFM (Design for Manufacturability) software solutions. Not only does Moldex3D identify issues surrounding manufacturability, it also determines problems that may arise during production, such as: surface defects, distortion and other potential production problems. A minor change in the design of the mold or product can already solve the problem at an early stage. Diagnosing the problem early on saves valuable time and resources.

Injection molding simulation: a virtual mold test

If the correct settings are applied, the results of the simulation offer the same capabilities as an initial test injection, displayed directly on the screen. The software confirms of the design before considering production. That's the power of Moldex3D. Often, the injection molding accounts for a large portion of the investment, not knowing the results in advance delays many projects and can significantly increase development and design costs. The use of Moldex3D helps to eliminate risks and offers insights into the results that can be expected on investment in the project.

Moldex3D optimises production parameters

There are several reasons why the parameters provided by Moldex3D are so valuable. The controls used during the injection molding process are a major factor when it comes to programming production cycle times and output. Moldex3D optimises the cycle time that can be achieved, based on the mold design and the data entered. If the production numbers do not match the expected output, the design or molding can be adjusted. This gives insight into the actual speed of the injection molding prior to production. This information is invaluable for sales, marketing, predicting and planning.

Moldex3D is essentially a time machine that looks ahead, makes a prediction, and reports back on production results. Reduce the inherent risk and uncertainty of your product design and mold building, and start incorporating Moldex3D as a standard tool in your design and simulation process. Would you like to know more about what Moldex3D can do for your organisation? Request the free trial and one of our consultants will help you on your way.

Discover the power of Moldex3D for injection moulding analysis.

Author: Bart Stuve

Published date: August 26, 2025

Explore our Technology. Access our downloads center.

Access NowStart your Digital Transformation with Emixa

We help businesses transform their digital future with cutting-edge technology and strategic products & services