News & Blogs

Stay updated with the latest news, insights, and expert blogs from Emixa. Explore industry trends, digital innovations, and company updates all in one place.

- Tecnomatix

Identifying Bottlenecks: Gaining Insights into the Production Process

Remaining competitive in a dynamic market, where customers demand fast, flexible responses at a competitive price, poses challenges for all manufacturing companies in the Netherlands. But the key to meeting these challenges lies in having insights into your production process, enabling you to rapidly adapt to new requirements. This raises the crucial question of pinpointing potential bottlenecks within your production. Manufacturing companies face a tough road ahead. The industry is fraught with uncertainty, both in the supply chain and with customers. Internal pressure on costs is increasing, partly due to global competition. As a result, companies are increasingly tailoring their production strategy to consumer demand. Yet, given the rapid shifts in demand, production must be able to respond very quickly. With a growing need for product variation, companies are compelled to significantly reduce the time it takes to introduce a new variant. Clear insights The trends outlined here present a significant challenge for production companies. In practice, the recurring issue boils down to a lack of insight—understanding how existing lines and layouts operate and their potential for flexible use or adaptation to meet the demand for a new product variant. This insight also emphasises the importance of visualisation. The demand for visual work, such as using 3D data, arises not only from the company itself to facilitate internal collaborations but also from customers and chain partners. The visual aspect has become a crucial element in communication and coordination between manufacturers and customers. Despite the inherent complexity, production companies must maintain flexibility to stay competitive in the market. Meeting customer demand faster and cheaper has become imperative. However, it's evident that classic tools like Excel or Visio are no longer sufficient for providing clear insight and overview. Production processes have evolved beyond their capabilities, with too many variables involved. These traditional tools have a significant drawback—they are built on basic assumptions due to technical limitations. Spreadsheets struggle to incorporate dynamic conditions like machine downtime and operator availability without high programming language skills. Meanwhile, management requires more detailed information than ever about the throughput of the new system. Virtual validation So, where does the solution lie? In one of our previous blogs, we highlighted the crucial role of seamless data exchange between engineering and production. Expanding on that concept, we are convinced that companies need to integrate digital tools into an increasing number of processes to effectively meet the demand for more product variations. These digital tools provide the capability to virtually validate production before implementing any changes. Many companies lack precise awareness of the issues within their current processes. We employ a step-by-step plan to thoroughly assess the current situation. This approach enables us to quickly pinpoint areas for potential improvements in existing lines. Whether it's for new investments in AGVs, an additional machine, or a new production line, we prefer to be involved as early as possible in the process. This proactive engagement not only contributes to achieving the most optimal and efficient production but also prevents misguided investments. Get in touch Interested in understanding how we would streamline the production process in your organisation? Contact us, and we'll be happy to share more with you.

- Data Analytics

Engineering and Manufacturing Demand a Central Data Platform

Consumers increasingly demand new product variations. To meet this demand, machine builders and high-tech suppliers must dramatically accelerate innovation and production. Designing, building and testing new machines – or modifying existing ones – can happen much faster when all company departments interlink data. Or better yet – centralise all data. Does your firm have a shared data repository? It will come as no surprise that consumer demand directly impacts suppliers. The growing consumer demand for new product variations results in shorter product life cycles. This means that new products, and consequently machines, need to come to market faster. To stay ahead of the competition, manufacturing companies must be able to cope with this increasing pressure on time-to-market. And that’s not all. Customers not only expect faster delivery of new machines, but also demand simultaneous improvements in quality and reductions in cost compared to previous versions. This pressures machine builders to enhance flexibility and efficiency across design, testing, and production. Only by optimising these critical processes can they stay competitive. Data in silos Digitisation is key here. The presence of a 360° view throughout the entire product lifecycle – from design to production and after-sales service – ensures optimal collaboration across all departments for effective product development. The end goal is staying ahead of the competition. Now, let's shift to the practical scenario. Business departments still often operate in silos, each equipped with its own systems and data. Once the product design is completed, engineering colleagues metaphorically toss the design over the dividing wall to the production department, which operates with its unique set of systems or, at times, relies on traditional tools like Excel, pen, and paper. There is no automatic flow of data between the departments. Drawing from personal experience, I've observed that engineering is frequently advanced in terms of digitalisation. However, a brief visit to the production department reveals a different story: paper-based work instructions, scattered emails, and Excel sheets dominate the landscape. The considerable investment in engineering digitisation doesn't reach its full potential unless production similarly embraces digital integration. Brakes on efficiency The lack of digital alignment between engineering and production can significantly impede the efficiency and flexibility that the company so desperately needs. Non-integrated, paper-based workflows make it challenging to provide feedback from production to engineering. Connecting with ERP systems proves difficult, requiring manual transcriptions of paper slips and bringing the risk of errors. Plus, there's no clear view of the production run status, delivered quality, errors, interruptions, and the like. Without exaggeration, engineers in such environments can dedicate up to 50% of their time to data collection and validation. When production alterations are required, the disjointed data systems often lead to unnecessary hours spent syncing updates. The lack of digital data flow also limits visual operations in production due to the absence of a link with engineering's 3D data. All these factors contribute to extended lead times. Shared data platform A company aiming to streamline engineering and production can achieve this by initially establishing a shared data platform. Goodbye to silos! Once the data is centrally available, the departments can collaborate more seamlessly. This leads to a quicker time-to-market, fewer issues related to production quality, and reduced recalls. In my opinion, digitalisation in this context begins with a unified repository for documents and bill of materials, alongside all mechanical, electronic, software, and simulation data. This single source of truth provides a solid foundation to optimise collaboration between departments, addressing the efficiency and flexibility of your Product Lifecycle Management strategically. Get in touch Curious about our advice on streamlining your Product Lifecycle Management? Contact us, and we’ll provide you with all the details.

- PLM

- Teamcenter

Teamcenter - Next Level Documentation Management

Would you rather your engineers just focus on technical work, or have them spend needless time searching through folders to locate documents? If you do not work in a PLM (Product Lifecycle Management) environment, it’s difficult to capture these documents and stick to the required formats. The PLM environment oversees the entire lifecycle of a product, from concept and design to production and product launch. This product life cycle includes different types of documentation such as: CAD drawings, test procedures, reports, marketing material, or user manuals. Product documentation is an essential component. It therefore must be: consistent with the product design and configuration, available on time, and in accordance with the company's documentation guidelines. The Teamcenter® document management solution can help you with this. Document management is much more than storing and sharing documents! Teamcenter® enables document management capabilities that operate within the PLM environment. This solution makes the standardisation and management of documents and processes easier. This, in turn, increases productivity and reduces cycle times. The advantages of Siemens Teamcenter® Document Management Accelerate time-to-market Increase productivity Improve product launch Reduce document confusion Unlike previous, standalone document management systems, documents that are managed in Teamcenter® link to all relevant parts, products, as well as other documents. In the event of any changes that are made, the impact on your document can quickly be identified. It is crucial that the correct version is used. This way you never miss important information and documents are always up to date! Teamcenter® incorporates document management capabilities throughout your product development environment: Working with templates Teamcenter predefines templates for different document types. For example, when creating a new document, Teamcenter will always select the correct template. This guarantees that the correct format will be used throughout the organisation. Synchronised data It is also possible to synchronise information contained in articles, or parts lists, for example, between all documents stored in Teamcenter. If the information in the document or in Teamcenter is changed, it will automatically be updated. This allows you to manage the information in one place and use it in multiple locations automatically, preventing costly errors in the process. Automatic PDF Another advantage of Teamcenter is the ability to view files in neutral formats. Any file type can be automatically opened in PDF to add comments, share with customers or associates, and verify authenticity using a digital signature without disclosing intellectual property rights. Secured documents Teamcenter provides the ideal all-in-one solution you need for securing access, modifying, and removing documents. The checkin and checkout option prevents multiple employees from overwriting the document at the same time. Integration with Office 365 allows different colleagues to work on the same document. Finally, the rights of access to documents can be set for each role, group or project. Are you looking to improve document management in your product development process? Contact us and request a free live demo with one of our consultants.

- PLM

The True Impact of Siemens Teamcenter Implementation

One of our customers, AAE is an advanced high-tech manufacturer that designs and produces solutions in Production Automation and Advanced Systems. AAE pushes the boundaries of technology, so their customers can be the most competitive player in their market. Their advanced solutions enable organisations to create smarter, faster, more stable and cost-saving production methods. AAE supplies a wide range of markets in various industries including the medical, automotive, semicon, food and drink, toys and games, office supplies, photovoltaic, analytical and the life sciences industry. As an organisation, they contribute to products and solutions that benefit society in so many ways, making us smarter, more innovative, conscientious, sustainable and safe, and, of course, more fun. In recent years, AAE has grown rapidly, both in terms of revenue and workforce. Whereas previously the lines of communication between the business operations and the shop floor were short and informal, the growth AAE is experiencing means that the organisation has had to formalise their technical management structure. The key being to create consistency with regard data integrity, i.e. a "Single Source of Truth". As a result, AAE needed to make further improvements in how they manage their technical documentation. Siemens Teamcenter provides the solution for this. Implementing Siemens Teamcenter has a huge impact within a company, especially within a high-tech organisation where the technical documentation forms the basis of the products that are delivered to customers. Data integrity is essential within a high-tech company like AAE, in order to deliver quality to their customers efficiently. Working with the so-called "Master Model" principle ensures that the data is managed in one place and that the entire organisation can rely blindly on the validity of the data, and use it without any issues. By integrating the various CAD applications and ERP within Teamcenter, the need to carry out manual transfers of technical data is reduced to a minimum. Advantages such as speed, reliability and a reduction in workload are the main drivers behind AAE choosing Teamcenter. The implementation of Teamcenter within AAE is divided into two phases. The first phase is focused on internal IP data, in which AAE is fully responsible for the management of this data. In the second phase, the focus is on securing external data, IP data managed by the customer. The introduction of Teamcenter impacts everyone at AAE from the engineers to production workers, to order intake and financial administration. "We were extremely pleased with the input from our colleagues at AAE. Often, these types of transitions are met with doubt or scepticism. If we’re going to do it then we do it properly, which is why the new system was viewed critically in the early stages. By informing everyone as much as possible about the possibilities the Teamcenter implementation offers, and communicating clearly the journey undertaken by the project group (and AAE as a whole), it has worked out well. `{`..`}` Based on the use of Emixa, we provided high-quality training to all employees, with plenty of time and space for dialogue, explanation, with mutual understanding and respect. As a project team, we made sure it was clear that we are always open to constructive criticism and feedback regarding the solutions that have been implemented.” Rob Hendriks, Project Manager PDM at AAE. In the early stages already, AAE chose for an active integration between Teamcenter and the ERP system (ISAH), so the entire organisation and business operations could benefit from the advantages Teamcenter offers. The system is based multi-cad integration with Siemens Teamcenter, Siemens NX, SolidWorks and EPLAN to safeguard the Engineering Bill of Materials (EBOM). A Manufacturing Bill of Materials (MBOM) can then be determined for production, with the help of Teamcenter, which is communicated with ERP. “AAE has found the use of Emixa to be particularly beneficial. There has always been, and still is, open and respectful communication between us. That’s not to say there weren’t some teething problems when discussing topics like, say, substantive solutions, planning or budgeting. After all, ‘no pain no gain’, as the saying goes.” - Rob Hendriks, Project Manager PDM at AAE. The first phase has been completed, in which the emphasis was on setting up the system and data model for internal IP data. The focus now shifts to setting up external IP data in Teamcenter. Aspects that are of particular interest to AAE include automated import and comparing external data in Teamcenter. Implementing a uniform formal change policy, supported by Teamcenter, will bring AAE a step closer to its overarching objective: continuing to push technological boundaries and providing its customers with the best possible advanced high-tech solutions available. Are you curious about whether integration with Teamcenter could benefit your company? Contact us to find out more.

- Manufacturing

How to Achieve Collaboration in the Supply Chain

The days when machine builders had to invent, develop and build everything themselves are long gone. Most modern companies have their own suppliers or are part of the supply chain of an OEM. This cooperation between Dutch manufacturing companies is of course very nice, but it also brings major challenges to the table. One of the most important ones? Finding out how to deal with the crucial data exchange that fosters seamless collaboration throughout the supply chain. Every manufacturing company, regardless of its core business and the industry to which it belongs, feels the increasing pressure of competition, decreasing margins, rising costs and staff shortages. To bring products to market quickly and without error, manufacturing companies can no longer afford to lose time on cumbersome, error-prone and manually-driven data exchange processes. The need for automation and smarter processes rises with increasing product complexity and creates a growing number of challenges. First of all, companies must deal with more and more complex data. Assemblies are getting bigger, whilst the number of electronic components, specifications and quality controls is on the rise. In addition, each company applies its own, often unique working methods and uses different tools and modes of operation when it comes to storing, supplying and structuring data. Standardisation is lacking, since companies usually do not have access to each other's systems. So how do you ensure data exchange between supply chain partners without being exposed to a cyber attack?

- Digital Twin

Digital Twin & Thread: From Complexity to Competitive Advantage

The complexity of contemporary product and production processes is increasing explosively. Companies have to deal with customised products, quality, cost reduction, flexibility, sustainability and so on. Complexity is the central theme for all these topics, but how can you turn this complexity into a competitive advantage? Most manufacturing companies know that they need to continuously evaluate and improve the product development process to keep up with the competition. To this end, incremental investments are constantly being made that consciously or unconsciously contribute to a total digital transformation. In previous blogs we have discussed various separate topics in the field of digitisation that are relevant for manufacturers. We have talked about: Breaking down the silos between engineering and production Gaining insight into production processes via simulation models The virtual commissioning of a line or machine The transition from 2D drawings to Model Based Definition Data exchange within the supply chain For all the topics above, they contribute to digitisation within manufacturing. Of course, there are many other important technologies or solutions besides these topics that we will explain in future blogs. This time, our focus is on the overarching theme that ties all these topics together: 'Digital Twins' and the 'Digital Thread.' As we engage with companies about these concepts, we observe a significant increase in manufacturing knowledge over recent years. While only a few years ago, these terms were relatively unfamiliar, it's now apparent that almost everyone has developed their own understanding of them. However, given the varied definitions we frequently encounter, this blog aims to articulate our perspective on these two terms. Digital Twin When we talk about digital twins, we often talk about different variants. For example, you can have a digital twin of your product, but also of your production process. In short, a digital twin for me is the digital counterpart of reality, where all relevant up-to-date information is connected. So when we talk about a digital twin of the product, we don't just mean the 3D CAD file. Although this is of course an important part of the digital twin, that file does not contain all the information. Think of all the requirements and specifications that determine the product, or the performance of the product itself. In our view, a complete digital twin of the product contains simulation models that predict, for example, the rigidity of a product or the air resistance. Of course, the same applies to the digital twin of production. This also includes all the tools, resources, actions, quality controls, programming, etc. required for actual production. Again, simulation models are included that can predict output, guarantee safety and ergonomics on the floor and prevent bottlenecks or collisions with robots and AGVs. The added value of these digital twins includes the fact that everything can be validated and prepared in a virtual environment before a physical product or process is set up. This helps companies bring better products to market faster and at lower cost. Even after the physical products and production processes have been set up, the digital twins offer added value. Most products and processes now contain numerous sensors that collect data on performance. This real-time data can flow back into the digital twins to provide additional insights and implement a process of continuous improvement. However, it is a prerequisite for this that the various applications and departments within companies are well-connected to each other. This brings me to the second term. Digital Thread When we talk about the 'Digital Thread' we mean one integrated stream of data across the different phases of the product development cycle. This means both a connection between the different departments within a company, such as sales, engineering, production and service, but also between the different applications within a company, such as CPQ, PLM, ERP, MES, etc. By connecting all the information, you create a digital thread. This creates traceability in the process. This traceability is becoming increasingly important. Consider the aviation or medical industry, for example. Because traceability ensures that the impact of a change is immediately transparent, and thus prevents mistakes from being made. Does a customer change a requirement halfway through the process? It is then immediately clear which functions and components need to be changed as a result, where they currently are in the process and who is working on them. Thanks to their predictability and traceability, the Digital Twin and Digital Thread can help companies turn increasing complexity into a competitive advantage. Up for a brainstorm? Curious about the other benefits of digital twins and the digital thread? Want to know what digitisation can mean for your business and how we can help you with that? Reach out to us, and we'll gladly provide you with more information.

- PLM

Collaborating in the Supply Chain: How do you do that?

Gone are the days when machine builders exclusively handled in-house development and construction. In the contemporary landscape, most companies either possess their own supply chain with various suppliers or operate as integral components within an Original Equipment Manufacturer's (OEM) supply chain. While this collaboration within Dutch manufacturing companies offers substantial benefits, it also presents significant challenges. How does one manage the critical exchange of data in this intricate web of partnerships? Every manufacturing entity, irrespective of its industry, feels the increasing pressure of competition, shrinking margins, rising costs and staff shortages. To bring products quickly and seamlessly to market, manufacturers can no longer afford the luxury of time-consuming data exchange, fraught with manual checks susceptible to errors. With increasing product complexity, this problem is only getting bigger and causes more and more challenges. Firstly, companies have to deal with more and more complex data: assemblies become larger, the number of electronic components increases, there are more specifications and quality checks. In addition, each company has its own way of working and provides data in a different structure. There is a lack of standards. Companies often also lack access to each other's systems. So, how do you ensure data is exchanged securely without exposing yourself to a cyberattack? Continuous stream of modifications The challenge often extends beyond a one-time data transfer. During the product development process, continuous modifications arise that need to be implemented properly. Keeping oversight and carefully recording all changes is a time-consuming task that usually has to be carried out by expensive engineers, who should actually be spending their time on completely different tasks. I still hear too often in the market that this leads to mistakes that only become visible late in the process - and therefore cost a lot of money. This might involve ordering the wrong products, older revisions going into production, increasing lead times with possible penalties from the OEM and a loss of trust in the supplier. Now what? We believe that a large part of this problem can be solved by automating and digitising current processes. No more reliance on email and Excel for manual back-and-forth data exchanges! Intelligent data importation is key, where the system can automatically compare data and process changes. The way you can do this largely depends on the data source. Is your customer's or supplier's data organized in folder structures, and does it arrive consistently at your end? Or do one or both parties have a Product Data Management (PDM) or Product Lifecycle Management (PLM) system where data is securely managed? In the latter case, there are possibilities to use an intermediate portal where data can safely flow from one system to the other. Regardless of the situation, achieving this necessitates gaining a comprehensive understanding of internal workflows and the modification rules (Change Management). By aligning your customer's or supplier's workflows, you can document this knowledge in templates or rules within a system. Only then can you start to automate. Get in touch Information exchange throughout the supply chain is a complex topic. Tackling this issue isn't straightforward, and there can be multiple ways to approach it. Curious about how we can assist you with this? Contact us, and we'll provide you with more details.

- PLM

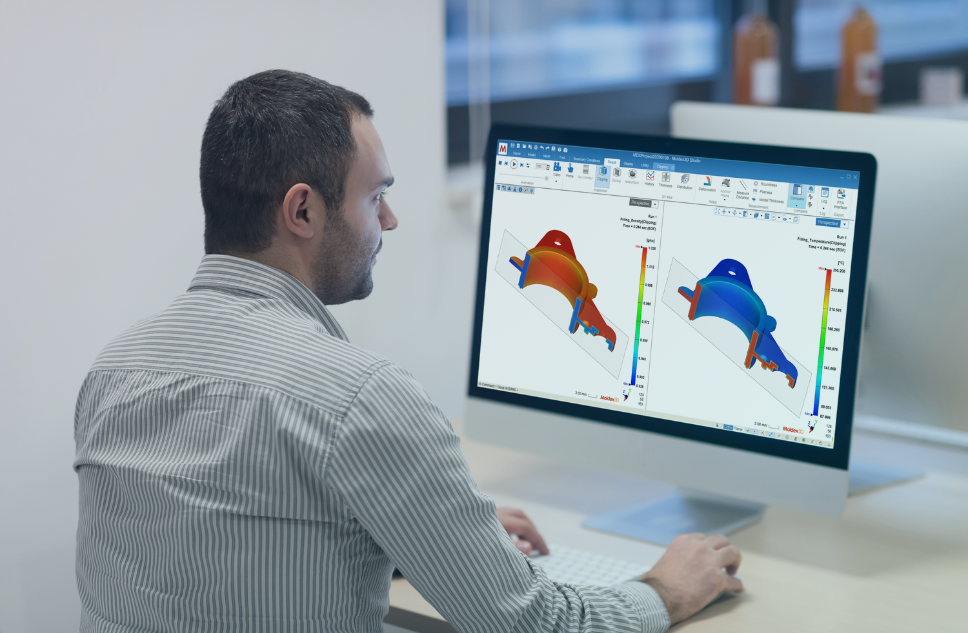

The Added Value of Moldex3D and Injection Moulding Analysis

Moldex3D is a software program developed to carry out accurate analyses and simulations of advanced plastic injection molding processes. This software enables you to optimise mold design, increase producibility and accelerate the time-to-market. This software helps you to predict and remedy challenges, by analysing and identifying any potential problems in the injection molding process, including temperature, pressure or shrinkage. 85% of common production problems that occur can be predicted and solved in advance. Injection molding simulation provides valuable insights into the design process, and future results in terms of production. This type of software offers major advantages in that it allows you to assess and qualify designs early, as well as being able to predict and remedy any risks in the product development process, prior to production. Most importantly, it saves time and reduces costs. Identify problems at an early stage In about 80% of cases, Moldex3D identifies design issues that will go undetected by standard DFM (Design for Manufacturability) software solutions. Not only does Moldex3D identify issues surrounding manufacturability, it also determines problems that may arise during production, such as: surface defects, distortion and other potential production problems. A minor change in the design of the mold or product can already solve the problem at an early stage. Diagnosing the problem early on saves valuable time and resources. Injection molding simulation: a virtual mold test If the correct settings are applied, the results of the simulation offer the same capabilities as an initial test injection, displayed directly on the screen. The software confirms of the design before considering production. That's the power of Moldex3D. Often, the injection molding accounts for a large portion of the investment, not knowing the results in advance delays many projects and can significantly increase development and design costs. The use of Moldex3D helps to eliminate risks and offers insights into the results that can be expected on investment in the project. Moldex3D optimises production parameters There are several reasons why the parameters provided by Moldex3D are so valuable. The controls used during the injection molding process are a major factor when it comes to programming production cycle times and output. Moldex3D optimises the cycle time that can be achieved, based on the mold design and the data entered. If the production numbers do not match the expected output, the design or molding can be adjusted. This gives insight into the actual speed of the injection molding prior to production. This information is invaluable for sales, marketing, predicting and planning. Moldex3D is essentially a time machine that looks ahead, makes a prediction, and reports back on production results. Reduce the inherent risk and uncertainty of your product design and mold building, and start incorporating Moldex3D as a standard tool in your design and simulation process. Would you like to know more about what Moldex3D can do for your organisation? Request the free trial and one of our consultants will help you on your way. Discover the power of Moldex3D for injection moulding analysis.

- PLM

Smoothly Optimise your Production Process with Simulation

IGS GeboJagema is a full-service partner in the healthcare industry, specialising in high-volume moulds. With a strong belief in delivering the highest quality in all their endeavours, the organisation enables healthcare companies supplying products on behalf of a brand supplier to produce top-notch items in large quantities. The moulds are produced with high precision tolerances, which requires high accuracy in engineering, manufacturing and validation. This allows them to offer an end-to-end solution encompassing design, engineering, qualification and supporting services to all their customers. “We dare to innovate!” - Rob Doorakkers, Chief Innovation Officer at IGS GeboJagema. To meet the high precision requirements, being able to tackle problems that may arise during the injection moulding process is an important step. These problems are often a combination of product geometry and the materials to be injection moulded, such as: Detecting air traps: Trapped air causes bubbles or voids in the products and can lead to surface finish issues. Using Moldex3D allows for visualisation of potential air traps in advance. Detecting heat concentrations: Heat concentrations in the product and in the mould indicate where cooling can be optimally applied and provide insight into the required cooling time. Detecting flow patterns: Wavy lines visible in the final product indicate how plastic fills the mould cavities and highlight potential issues. Detecting the pressure expected in the mould In the past, simulations were outsourced due to a lack of in-house expertise and manpower. To speed up the simulation of the injection moulding process and add value for clients, IGS GeboJagema chose to bring simulation in-house. IGS GeboJagema selected Moldex3D based on its seamless integration into existing processes, combined with associated costs, capabilities, and support for software implementation. "The assistance we received during the procurement, initiation, training, and the promptness in addressing technical queries throughout simulations significantly influenced our decision to opt for Emixa Industry Solutions." - Rob Doorakkers, Chief Innovation Officer at IGS GeboJagema. The implementation of Moldex3D has revolutionised IGS GeboJagema's simulation process, resulting in a faster, more optimised, and thoroughly validated production process. Fast adjustments during mould validation have become a reality, and simulation serves as a crucial tool for validating optimisation ideas before committing to costly mould implementations. This software allows the proactive detection of issues like air traps, heat concentrations, and flow patterns, preventing expensive mould modifications and streamlining the validation process. Moving forward, IGS GeboJagema plans to engage in multiple straightforward simulations as part of the quotation preparation process, gradually building the necessary expertise to conduct extensive simulations independently. The company envisions a future where they continually explore and expand the possibilities within simulation. "What sets us apart is our ability to strategically place elements such as venting and cooling in advance, significantly reducing the optimisation timeline. Conducting cooling simulations provides a comprehensive view of temperature dynamics in the mould, enabling us to effectively inform and persuade customers during the design phase." – Rob Doorakkers, Chief Innovation Officer at IGS GeboJagema Discover the power of Moldex3D for performing injection moulding analysis.