News & Blogs

Stay updated with the latest news, insights, and expert blogs from Emixa. Explore industry trends, digital innovations, and company updates all in one place.

- PLM

- Teamcenter

Teamcenter - Next Level Documentation Management

Would you rather your engineers just focus on technical work, or have them spend needless time searching through folders to locate documents? If you do not work in a PLM (Product Lifecycle Management) environment, it’s difficult to capture these documents and stick to the required formats. The PLM environment oversees the entire lifecycle of a product, from concept and design to production and product launch. This product life cycle includes different types of documentation such as: CAD drawings, test procedures, reports, marketing material, or user manuals. Product documentation is an essential component. It therefore must be: consistent with the product design and configuration, available on time, and in accordance with the company's documentation guidelines. The Teamcenter® document management solution can help you with this. Document management is much more than storing and sharing documents! Teamcenter® enables document management capabilities that operate within the PLM environment. This solution makes the standardisation and management of documents and processes easier. This, in turn, increases productivity and reduces cycle times. The advantages of Siemens Teamcenter® Document Management Accelerate time-to-market Increase productivity Improve product launch Reduce document confusion Unlike previous, standalone document management systems, documents that are managed in Teamcenter® link to all relevant parts, products, as well as other documents. In the event of any changes that are made, the impact on your document can quickly be identified. It is crucial that the correct version is used. This way you never miss important information and documents are always up to date! Teamcenter® incorporates document management capabilities throughout your product development environment: Working with templates Teamcenter predefines templates for different document types. For example, when creating a new document, Teamcenter will always select the correct template. This guarantees that the correct format will be used throughout the organisation. Synchronised data It is also possible to synchronise information contained in articles, or parts lists, for example, between all documents stored in Teamcenter. If the information in the document or in Teamcenter is changed, it will automatically be updated. This allows you to manage the information in one place and use it in multiple locations automatically, preventing costly errors in the process. Automatic PDF Another advantage of Teamcenter is the ability to view files in neutral formats. Any file type can be automatically opened in PDF to add comments, share with customers or associates, and verify authenticity using a digital signature without disclosing intellectual property rights. Secured documents Teamcenter provides the ideal all-in-one solution you need for securing access, modifying, and removing documents. The checkin and checkout option prevents multiple employees from overwriting the document at the same time. Integration with Office 365 allows different colleagues to work on the same document. Finally, the rights of access to documents can be set for each role, group or project. Are you looking to improve document management in your product development process? Contact us and request a free live demo with one of our consultants.

- PLM

- Teamcenter

- +1

MTA Accelerates Innovation with Siemens NX CAD and Teamcenter

A company’s success often depends on the efficiency and future readiness of its processes. For MTA, innovation is at the core of everything they do. As a leading developer and producer of high-tech mechatronic systems, MTA specializes in cutting-edge solutions for industries such as medical technology, agriculture, and industrial automation. From surgical robots to 3D metal printers, MTA delivers precision-engineered products that set new industry standards. However as the complexity of their designs and processes grew, MTA recognised the need for a more robust, integrated solution to support their ambitious goals. Enter Siemens NX CAD and Teamcenter —an advanced, transformative combination that has empowered MTA to stay ahead.

- PLM

The True Impact of Siemens Teamcenter Implementation

One of our customers, AAE is an advanced high-tech manufacturer that designs and produces solutions in Production Automation and Advanced Systems. AAE pushes the boundaries of technology, so their customers can be the most competitive player in their market. Their advanced solutions enable organisations to create smarter, faster, more stable and cost-saving production methods. AAE supplies a wide range of markets in various industries including the medical, automotive, semicon, food and drink, toys and games, office supplies, photovoltaic, analytical and the life sciences industry. As an organisation, they contribute to products and solutions that benefit society in so many ways, making us smarter, more innovative, conscientious, sustainable and safe, and, of course, more fun. In recent years, AAE has grown rapidly, both in terms of revenue and workforce. Whereas previously the lines of communication between the business operations and the shop floor were short and informal, the growth AAE is experiencing means that the organisation has had to formalise their technical management structure. The key being to create consistency with regard data integrity, i.e. a "Single Source of Truth". As a result, AAE needed to make further improvements in how they manage their technical documentation. Siemens Teamcenter provides the solution for this. Implementing Siemens Teamcenter has a huge impact within a company, especially within a high-tech organisation where the technical documentation forms the basis of the products that are delivered to customers. Data integrity is essential within a high-tech company like AAE, in order to deliver quality to their customers efficiently. Working with the so-called "Master Model" principle ensures that the data is managed in one place and that the entire organisation can rely blindly on the validity of the data, and use it without any issues. By integrating the various CAD applications and ERP within Teamcenter, the need to carry out manual transfers of technical data is reduced to a minimum. Advantages such as speed, reliability and a reduction in workload are the main drivers behind AAE choosing Teamcenter. The implementation of Teamcenter within AAE is divided into two phases. The first phase is focused on internal IP data, in which AAE is fully responsible for the management of this data. In the second phase, the focus is on securing external data, IP data managed by the customer. The introduction of Teamcenter impacts everyone at AAE from the engineers to production workers, to order intake and financial administration. "We were extremely pleased with the input from our colleagues at AAE. Often, these types of transitions are met with doubt or scepticism. If we’re going to do it then we do it properly, which is why the new system was viewed critically in the early stages. By informing everyone as much as possible about the possibilities the Teamcenter implementation offers, and communicating clearly the journey undertaken by the project group (and AAE as a whole), it has worked out well. `{`..`}` Based on the use of Emixa, we provided high-quality training to all employees, with plenty of time and space for dialogue, explanation, with mutual understanding and respect. As a project team, we made sure it was clear that we are always open to constructive criticism and feedback regarding the solutions that have been implemented.” Rob Hendriks, Project Manager PDM at AAE. In the early stages already, AAE chose for an active integration between Teamcenter and the ERP system (ISAH), so the entire organisation and business operations could benefit from the advantages Teamcenter offers. The system is based multi-cad integration with Siemens Teamcenter, Siemens NX, SolidWorks and EPLAN to safeguard the Engineering Bill of Materials (EBOM). A Manufacturing Bill of Materials (MBOM) can then be determined for production, with the help of Teamcenter, which is communicated with ERP. “AAE has found the use of Emixa to be particularly beneficial. There has always been, and still is, open and respectful communication between us. That’s not to say there weren’t some teething problems when discussing topics like, say, substantive solutions, planning or budgeting. After all, ‘no pain no gain’, as the saying goes.” - Rob Hendriks, Project Manager PDM at AAE. The first phase has been completed, in which the emphasis was on setting up the system and data model for internal IP data. The focus now shifts to setting up external IP data in Teamcenter. Aspects that are of particular interest to AAE include automated import and comparing external data in Teamcenter. Implementing a uniform formal change policy, supported by Teamcenter, will bring AAE a step closer to its overarching objective: continuing to push technological boundaries and providing its customers with the best possible advanced high-tech solutions available. Are you curious about whether integration with Teamcenter could benefit your company? Contact us to find out more.

- Siemens

- PLM

- +1

Celebrating Excellence: InMotion Computable Award Nomination

We are proud to announce that this year 'InMotion - Charging Ahead Towards Le Mans e-Racing' has been nominated in the category of Best Educational Projects in ICT. Join us in celebrating this achievement and discover more about the InMotion Team's journey. Vote now!

- PLM

Collaborating in the Supply Chain: How do you do that?

Gone are the days when machine builders exclusively handled in-house development and construction. In the contemporary landscape, most companies either possess their own supply chain with various suppliers or operate as integral components within an Original Equipment Manufacturer's (OEM) supply chain. While this collaboration within Dutch manufacturing companies offers substantial benefits, it also presents significant challenges. How does one manage the critical exchange of data in this intricate web of partnerships? Every manufacturing entity, irrespective of its industry, feels the increasing pressure of competition, shrinking margins, rising costs and staff shortages. To bring products quickly and seamlessly to market, manufacturers can no longer afford the luxury of time-consuming data exchange, fraught with manual checks susceptible to errors. With increasing product complexity, this problem is only getting bigger and causes more and more challenges. Firstly, companies have to deal with more and more complex data: assemblies become larger, the number of electronic components increases, there are more specifications and quality checks. In addition, each company has its own way of working and provides data in a different structure. There is a lack of standards. Companies often also lack access to each other's systems. So, how do you ensure data is exchanged securely without exposing yourself to a cyberattack? Continuous stream of modifications The challenge often extends beyond a one-time data transfer. During the product development process, continuous modifications arise that need to be implemented properly. Keeping oversight and carefully recording all changes is a time-consuming task that usually has to be carried out by expensive engineers, who should actually be spending their time on completely different tasks. I still hear too often in the market that this leads to mistakes that only become visible late in the process - and therefore cost a lot of money. This might involve ordering the wrong products, older revisions going into production, increasing lead times with possible penalties from the OEM and a loss of trust in the supplier. Now what? We believe that a large part of this problem can be solved by automating and digitising current processes. No more reliance on email and Excel for manual back-and-forth data exchanges! Intelligent data importation is key, where the system can automatically compare data and process changes. The way you can do this largely depends on the data source. Is your customer's or supplier's data organized in folder structures, and does it arrive consistently at your end? Or do one or both parties have a Product Data Management (PDM) or Product Lifecycle Management (PLM) system where data is securely managed? In the latter case, there are possibilities to use an intermediate portal where data can safely flow from one system to the other. Regardless of the situation, achieving this necessitates gaining a comprehensive understanding of internal workflows and the modification rules (Change Management). By aligning your customer's or supplier's workflows, you can document this knowledge in templates or rules within a system. Only then can you start to automate. Get in touch Information exchange throughout the supply chain is a complex topic. Tackling this issue isn't straightforward, and there can be multiple ways to approach it. Curious about how we can assist you with this? Contact us, and we'll provide you with more details.

- PLM

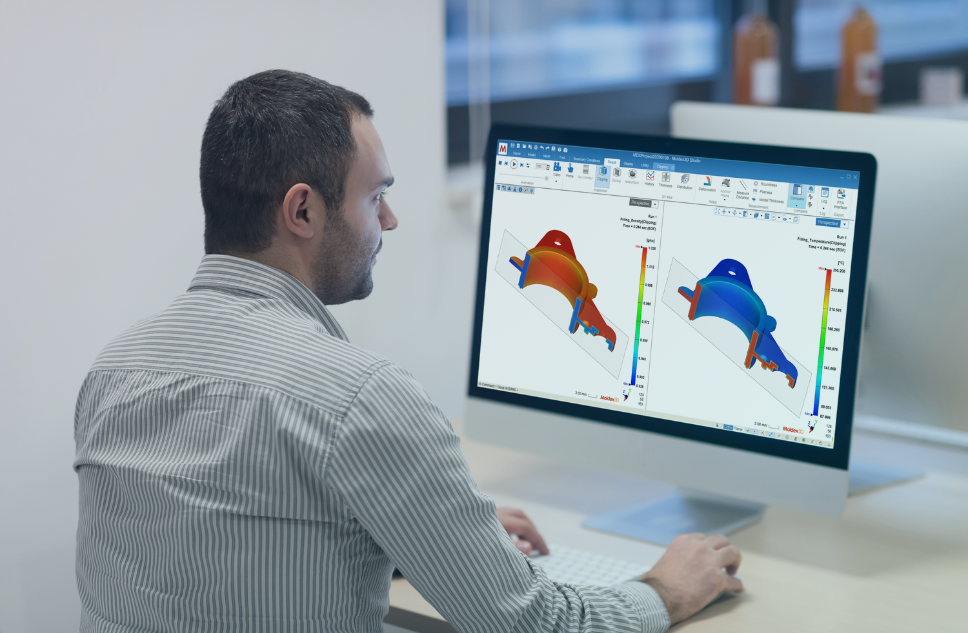

The Added Value of Moldex3D and Injection Moulding Analysis

Moldex3D is a software program developed to carry out accurate analyses and simulations of advanced plastic injection molding processes. This software enables you to optimise mold design, increase producibility and accelerate the time-to-market. This software helps you to predict and remedy challenges, by analysing and identifying any potential problems in the injection molding process, including temperature, pressure or shrinkage. 85% of common production problems that occur can be predicted and solved in advance. Injection molding simulation provides valuable insights into the design process, and future results in terms of production. This type of software offers major advantages in that it allows you to assess and qualify designs early, as well as being able to predict and remedy any risks in the product development process, prior to production. Most importantly, it saves time and reduces costs. Identify problems at an early stage In about 80% of cases, Moldex3D identifies design issues that will go undetected by standard DFM (Design for Manufacturability) software solutions. Not only does Moldex3D identify issues surrounding manufacturability, it also determines problems that may arise during production, such as: surface defects, distortion and other potential production problems. A minor change in the design of the mold or product can already solve the problem at an early stage. Diagnosing the problem early on saves valuable time and resources. Injection molding simulation: a virtual mold test If the correct settings are applied, the results of the simulation offer the same capabilities as an initial test injection, displayed directly on the screen. The software confirms of the design before considering production. That's the power of Moldex3D. Often, the injection molding accounts for a large portion of the investment, not knowing the results in advance delays many projects and can significantly increase development and design costs. The use of Moldex3D helps to eliminate risks and offers insights into the results that can be expected on investment in the project. Moldex3D optimises production parameters There are several reasons why the parameters provided by Moldex3D are so valuable. The controls used during the injection molding process are a major factor when it comes to programming production cycle times and output. Moldex3D optimises the cycle time that can be achieved, based on the mold design and the data entered. If the production numbers do not match the expected output, the design or molding can be adjusted. This gives insight into the actual speed of the injection molding prior to production. This information is invaluable for sales, marketing, predicting and planning. Moldex3D is essentially a time machine that looks ahead, makes a prediction, and reports back on production results. Reduce the inherent risk and uncertainty of your product design and mold building, and start incorporating Moldex3D as a standard tool in your design and simulation process. Would you like to know more about what Moldex3D can do for your organisation? Request the free trial and one of our consultants will help you on your way. Discover the power of Moldex3D for injection moulding analysis.

- PLM

Smoothly Optimise your Production Process with Simulation

IGS GeboJagema is a full-service partner in the healthcare industry, specialising in high-volume moulds. With a strong belief in delivering the highest quality in all their endeavours, the organisation enables healthcare companies supplying products on behalf of a brand supplier to produce top-notch items in large quantities. The moulds are produced with high precision tolerances, which requires high accuracy in engineering, manufacturing and validation. This allows them to offer an end-to-end solution encompassing design, engineering, qualification and supporting services to all their customers. “We dare to innovate!” - Rob Doorakkers, Chief Innovation Officer at IGS GeboJagema. To meet the high precision requirements, being able to tackle problems that may arise during the injection moulding process is an important step. These problems are often a combination of product geometry and the materials to be injection moulded, such as: Detecting air traps: Trapped air causes bubbles or voids in the products and can lead to surface finish issues. Using Moldex3D allows for visualisation of potential air traps in advance. Detecting heat concentrations: Heat concentrations in the product and in the mould indicate where cooling can be optimally applied and provide insight into the required cooling time. Detecting flow patterns: Wavy lines visible in the final product indicate how plastic fills the mould cavities and highlight potential issues. Detecting the pressure expected in the mould In the past, simulations were outsourced due to a lack of in-house expertise and manpower. To speed up the simulation of the injection moulding process and add value for clients, IGS GeboJagema chose to bring simulation in-house. IGS GeboJagema selected Moldex3D based on its seamless integration into existing processes, combined with associated costs, capabilities, and support for software implementation. "The assistance we received during the procurement, initiation, training, and the promptness in addressing technical queries throughout simulations significantly influenced our decision to opt for Emixa Industry Solutions." - Rob Doorakkers, Chief Innovation Officer at IGS GeboJagema. The implementation of Moldex3D has revolutionised IGS GeboJagema's simulation process, resulting in a faster, more optimised, and thoroughly validated production process. Fast adjustments during mould validation have become a reality, and simulation serves as a crucial tool for validating optimisation ideas before committing to costly mould implementations. This software allows the proactive detection of issues like air traps, heat concentrations, and flow patterns, preventing expensive mould modifications and streamlining the validation process. Moving forward, IGS GeboJagema plans to engage in multiple straightforward simulations as part of the quotation preparation process, gradually building the necessary expertise to conduct extensive simulations independently. The company envisions a future where they continually explore and expand the possibilities within simulation. "What sets us apart is our ability to strategically place elements such as venting and cooling in advance, significantly reducing the optimisation timeline. Conducting cooling simulations provides a comprehensive view of temperature dynamics in the mould, enabling us to effectively inform and persuade customers during the design phase." – Rob Doorakkers, Chief Innovation Officer at IGS GeboJagema Discover the power of Moldex3D for performing injection moulding analysis.

- PLM

Hennes de Ridder about modular construction: 'Legoisation'

Hennes de Ridder is an Emeritus Professor of Integral Design at TU Delft. As a 'construction critic', he is frustrated by the constant reinvention of the wheel in the sector. We talked to him about how modular construction or 'Legoisation' could push the sector to new levels.

- PLM

- Digital Transformation

Meet Emixa, your Partner for Digital Transformation

After a period of thorough preparation and refinement, the moment has arrived: our new consortium for digital transformation services launches its name: Emixa, accompanied by a new website and corporate identity. With Emixa, the companies Appronto, cards PLM Solutions, Dimensys Process & IT Consulting, Magnus Digital and OnePLM Limited have joined forces to complement one another’s services and provide customers with innovative, high-quality, and full-service solutions in the field of digital transformation. Placing a special focus on the manufacturing industry, also known as 'Industry 4.0', using Siemens, SAP, Mendix and other leading technologies. Emixa is the only specialist that can realize the combination of Siemens/Mendix/SAP technology solutions. For clients this offers a unique one-stop shop that delivers the integrated solutions for next level digital transformation. Every industry has its own dynamics, with its own issues and challenges. Focussing on specific industries enables us to closely follow the trends and developments and to provide extra added value to companies in those markets. It is our ambition to make the most impact for our clients, as we already have been doing for decades within the technology consultancy firms part of Emixa. Growth through a buy-and-build strategy With the financial support of investor Holland Capital, Emixa is able to follow a buy-and-build strategy that allows the consortium to expand its business and service portfolio. The five companies that are united in Emixa employ a total of 420 people and focus on issues related to process optimisation, product lifecycle and asset management, IT architecture, low-code applications, system integrations, data analytics and change management. Emixa has the ambition to become one of the leading players in Western Europe and expand its established presence in Belgium, the Netherlands and the United Kingdom to the DACH region. The companies that form Emixa will remain active under their own names and strive to grow their services related to digital transformation. Each in its own way, the companies united in Emixa make a major contribution to organisations in various sectors, such as: manufacturing, (online) retail, logistics, construction, infrastructure, financial services and education. “The world is changing at a rapid pace. To remain competitive, companies have to choose a business model and complementary IT architecture that allow them to lead the way. Due to the powerful and unique combination of industry knowledge and technology expertise in the field of ERP, low-code applications, integrations and PLM solutions, we enable our customers to win in the challenging era of full-scale digitisation”, says Emixa CEO Peter-Jan Simons. The companies behind Emixa Emixa is a consortium that combines the knowledge, expertise and specialities of several renowned companies. Appronto Appronto was founded in 2013 in the Dutch city of Breda. The company focuses on the development of digital solutions for complex issues. Appronto is a specialist in the development of low-code solutions on the Mendix platform and in the realisation of system integrations via Boomi's cloud integration platform. In 2021, Appronto became the first European Siemens Smart Expert Partner, received the Boomi Partner Spotlight Award and was chosen as Siemens’ Top Cloud Partner in the Benelux area. cards PLM Solutions cards PLM Solutions was founded in 1999 and has locations in Best (NL) and Genk (B). With a team of 56 professionals, the organisation specialises in the digitisation of business processes and information flows within the manufacturing industry. Many of the company’s customers are active in industries such as automotive, aerospace, high-tech machine building, medical devices, and consumer goods. Over the years, the company has developed into a specialised product lifecycle management (PLM) solutions provider. cards is a Siemens Platinum Expert Partner for Siemens Digital Industries Software. Dimensys Dimensys was founded in the year 2000 and helps companies achieve operational excellence in their business processes. Dimensys makes the life cycle of assets and products transparent, predictable and repeatable. This allows organisations to use assets more effectively. The company uses years of experience in the knowledge domains of asset and product lifecycle management, project and portfolio management, and supply chain management. Dimensys is a certified SAP Gold Partner, SAP Partner Center of Expertise and SAP Recognized Expertise Partner. Magnus Digital Magnus, founded in 1990, was the first SAP partner and one of the first Mendix partners in the Netherlands. Magnus Digital is an innovative IT and organisational consultancy agency that works with leading clients. Its portfolio contains a wide range of digital services, from advice to realisation. With approximately 100 consultants, it provides services related to digital transformation, data analytics, ERP implementations, and the development of low-code solutions. It also unburdens customers of the management of these solutions. Magnus Digital is active in retail, FMCG, wholesale, manufacturing, education, transport, construction, and several other industries. OnePLM OnePLM is one of the world's largest Siemens Digital Industries Software Partners and the number one European Partner. The company has more than 25 years of industry experience and employs a team of 107 people. OnePLM provides PLM services and solutions to manufacturing companies in the UK and Ireland, both independent users and OEMs. In addition, OnePLM provides training, consultancy and support to a wide range of software customers. Holland Capital Over the past 40 years, Holland Capital has successfully invested in more than 150 Dutch SMEs. Using a clear, socially responsible and sustainable investment strategy, the company is active in the attractive growth markets of healthcare and technology. Holland Capital's investment team seeks to build an open, sustainable and professional relationship with the management teams of the companies in which it invests, with the common goal of achieving sustainable growth. More information Would you like to know more about Emixa? And are you curious about our solutions that allow you to speed up your digital transformation? Then don’t hesitate to contact us. We would be delighted to meet you!