News & Blogs

Stay updated with the latest news, insights, and expert blogs from Emixa. Explore industry trends, digital innovations, and company updates all in one place.

- Applications

- PLM

- +1

Pop Vriend Seeds adds Low Code to ICT landscape with the Pop App

The growing global population and demand for healthy, vitamin-rich food are driving the vegetable seed market worldwide. Pop Vriend Seeds, based in Andijk in West Friesland, is a major player in this industry. To better equip its operations for the demands and challenges of the digital era, Pop Vriend Seeds partnered with Emixa. We spoke with Jits Ursem, ICT Manager at the company, about the specifics and benefits of the application developed collaboratively by Pop Vriend Seeds and Emixa.

- PLM

- ERP Software

Revolutionize Your Design-To-Operate Process with SAP and Siemens

In the fast-evolving world of manufacturing, agility and precision are essential. However, misaligned data between design and manufacturing systems is a major factor contributing to production delays. With critical product and production information scattered across ERP and PLM systems, seamless communication remains the missing link in achieving Industry 4.0 goals.

- PLM

The Digital Machine Shop: The Road to Shorter Production Times

The Digital Machine Shop helps companies stay competitive, design the right products, and find the best way to manufacture them. This data-driven environment transforms production and the business by seamlessly connecting all elements of your operations, such as processes, machines, robots, and people. This model includes a fully digitised, faster production process - ranging from preparation to the final manufacturing of products or components. A model that can be used in all industries including aerospace, medical devices, and industrial machinery manufacturing. The Digital Machine Shop includes two processes: the manufacturing process and the inspection process. A component model designed in CAD software is the starting point for executing these processes. In the first step of the manufacturing process, preparations are made to turn the component model into a milled product. This involves looking at positioning, material use, and the steps to be performed. This is the preparatory phase for step two: programming the milling paths. In this step, a milling programme is created by CAM software through different operations. This NC programming provides the basis for controlling the machine. To prevent errors and to set up the milling process in an optimal way, the milling paths are simulated. A 3D simulation sets the machine in motion virtually to predict the milling process and detect and resolve errors early. At the same time as implementing the Digital Machine Shop method, the measurement process starts. In this stage, a virtual measurement takes place, which can be performed using CMM software that controls the automated measuring machine. A measurement plan is created with the help of PMI data to formulate the necessary measurement values. The probe path of this measurement plan is then programmed as the next phase in the process. To check the feasibility of this probe path, it is virtually set in motion by 3D simulation and adjusted where necessary. Benefits of the Digital Machine Shop: Increased machine utilisation Reduced machine cycle time Faster set-up Precision Machining Improved quality inspections Enables more complex products Innovative technologies New business models In the Digital Machine Shop, Siemens software ensures seamless information flow throughout the entire production process, eliminating the need for transitions between different software systems. Any changes made at the start of the process can easily and quickly be implemented in the final step. Using the same model for the production process ensures faster and more effective operations. If you have a machine shop, you know production time is crucial. Digital automation of production achieves first-time-right to shorten throughput time and accelerate time-to-market. If you aim to optimise and accelerate your production process, the Digital Machine Shop is your ideal starting point! Would you like to learn more on this topic? Download the eBook on the roadmap to a Digital Machine Shop or watch our webinar on getting more out of your current machinery!

- PLM

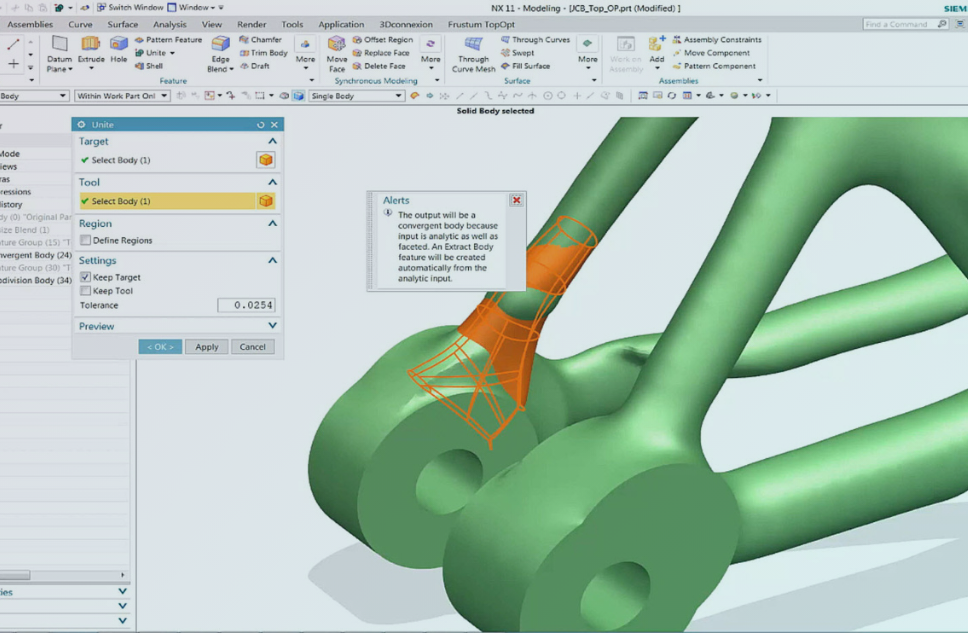

Reap all the Benefits of Additive Manufacturing

Companies are challenged every day by their customers with requests for more complex products, in smaller batches, with shorter lead times and at lower prices. An almost impossible ask, but if your competitor can deliver, you can't fall behind. Innovative technologies like Additive Manufacturing (AM) can improve and streamline your processes. When used correctly, AM offers numerous advantages over conventional production technologies. It brings about a revolutionary shift in the way we manufacture parts across various industries, catering not only to big businesses but also to small and medium enterprises. Additive Manufacturing in the product lifecycle Additive Manufacturing, also called 3D printing, has existed for over 35 years. But considering we've used conventional tech like subtractive and forming processes for thousands of years, you could say we've only just begun tapping into AM's potential. Starting in the '80s as a rapid prototyping tech, it's now increasingly used across the product lifecycle. Diverse applications need different materials and processes. Luckily nowadays there are printers that easily switch materials, vastly expanding possibilities. With professional, affordable desktop 3D printers you can print most of your prototyping and tooling applications quickly, cheaply and in-house. For some applications, it's even possible to print end-use parts or spares. Prototype 3D print your visual and functional prototypes to detect issues earlier, test new features and cut down time-to-market. Tooling Through the printing of production tooling, the ability to craft custom tools becomes a faster, more cost-effective, and in-house possibility. But the real value lies in the impact these custom tools can have on your processes, making them more efficient, rapid and safe. Production part Using 3D printing as a production technology to manufacture end-use parts makes it possible to create components that would be impossible with conventional manufacturing methods. Spare parts By 3D printing your spare parts on-demand, you can reduce inventory, storage space, and waste. Combining this with on-site printing also lowers transportation and packaging costs. Benefits of Siemens NX™ Additive Manufacturing Greater design freedom Customisation, enabling lot size 1 Utilisation of only essential materials Part consolidation and function integration Enhanced performance Metamaterials Print "on-demand" and "on-location" Industrial Additive Manufacturing For advanced applications, industrial 3D printers are sometimes the best solution due to specific material needs, build volume, capacity or resolution. An increasing number of companies successfully print a wide range of apps across sectors. But AM isn't a standalone process - upstream and downstream procedures must be considered too. Design for Additive Manufacturing (DFAM) Every production process has design rules and tools. As "Additive" is the very opposite of conventional "subtractive" manufacturing, traditional design tools don't always give the needed results. You don't remove material from a block, only adding it where necessary. That's why Siemens NX developers have added new design capabilities in recent years, helping designers fully harness AM's potential. AM Build Preparation & Simulation In 3D printing, the orientation of a part in the printer plays a crucial role, affecting strength, quality, costs, print times, material usage, and post-processing. Siemens NX's Build Preparation functionality offers orientation guidance, allowing you to save the desired orientation directly in the CAD model, ensuring consistent and repeatable outcomes. CNC Post-Processing Once your metal print is complete, the removal of metal supports is still necessary. Manual removal can be labor-intensive and lacks repeatability. This process can be automated via CNC milling, automatically eliminating supports and ensuring correct dimensions and surface finish. Programming and simulating the milling process can also be done in Siemens NX, preventing collisions and milling issues. Whether you're new or experienced in 3D printing, just exploring its potential or running industrial printers 24/7. We're here to support your business every step of the way to successfully implement Additive Manufacturing.

- PLM

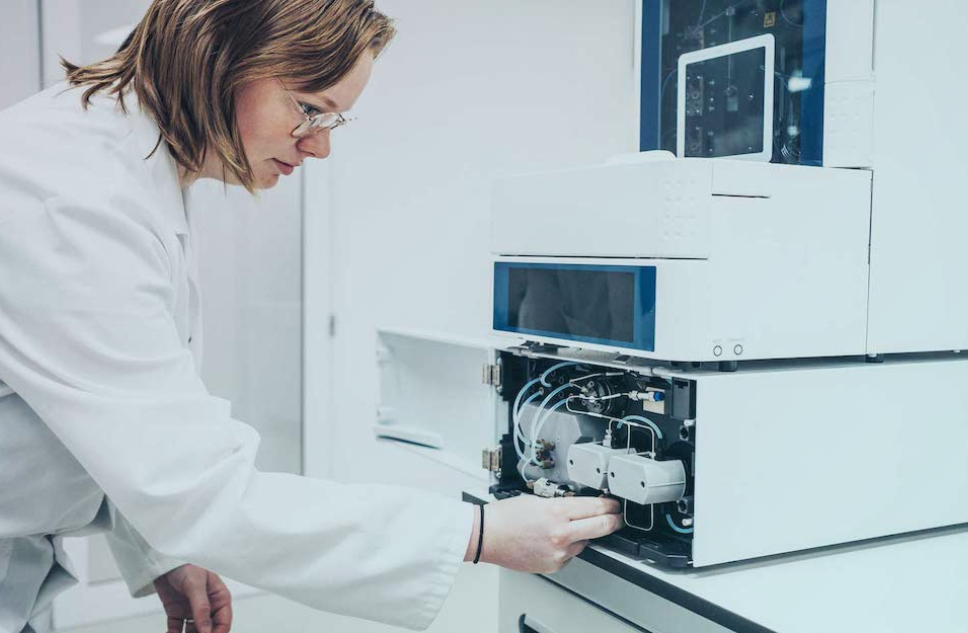

Coherent Project Documentation with Polarion

Spark Holland is a supplier of innovative sample introduction, extraction, and separation technology for analytical systems such as HPLC, MS, GC, and NMR. Spark gathers user feedback and seeks to understand typical issues in the analytical laboratory, focusing on product development towards simplicity and reliability. To create products that prioritise simplicity and reliability, it's essential to use a user-friendly, open, and easily understandable tool for requirement management. Shifting away from disjointed documents and spreadsheets, which previously formed the foundation of requirements management, became a challenge as projects grew more complex, making traceability nearly impossible. In a proof of concept, Polarion not only addressed the traceability issue immediately but also led the team to reevaluate the development process, resulting in a simplification step. Polarion Application Lifecycle Management enables teams to collaborate easily and securely on shared documentation. You can define who can see what, who can make changes, and when, through detailed permissions and robust configurable workflow automation. Additionally, Polarion has an FDA-approved electronic signature process. "Emixa Industry Solutions has consistently demonstrated expertise and reliability in addressing our Product Lifecycle Management needs over the years. Including them in our shortlist of vendors was a logical choice due to their knowledge and ability to meet customer requirements precisely. Their extensive partner network enables them to address any gaps in demand." - Nils Reuvers, IT Manager at Spark Holland B.V. The implementation of Polarion has resulted in more streamlined, improved, and cohesive project documentation with comprehensive, readily accessible traceability, all while minimising administrative overhead. Polarion has facilitated easier compliance with legal standards and regulations, creating clarity and improving the working process within product development. Want to learn more about this? Contact us.

- PLM

The Digital Shopfloor Scan: Uncover Operational Improvements

The manufacturing industry is under increasing pressure to operate more efficiently, flexibly and competitively. Digitalisation plays a crucial role in this, yet many companies still struggle with how to approach this transformation effectively. Where to start? Which processes offer the most room for improvement? The Digital Shopfloor Scan helps you answer these questions.

- NX Design

- PLM

- +3

Emixa and WSR Extend Technical Partnership for BTCC 2024

Emixa proudly announces the continuation of its technical partnership with West Surrey Racing (WSR) for the 2024 British Touring Car Championship (BTCC) season. Building on a decade-long collaboration, this partnership leverages Emixa's expertise in Siemens Digital Industries Software to enhance WSR's competitive edge on the track.

- PLM

- Digital Transformation

Operational Excellence: How Manufacturing Companies Can Work Smarter, Not Harder

In today’s volatile world, the manufacturing industry is under increasing pressure to work smarter, not harder. Operational Excellence plays a key part in this. How can manufacturing companies achieve operational excellence? And how can digital technologies support them in this? Our experts, Feike de Groot, Robert te Vaarwerk, and Vincent Verheul, show you a clear growth path for operational excellence.

- PLM

- Mendix

- +1

Digital Maturity: How to Turn Your Digital Strategy into Reality

The manufacturing industry is under increasing pressure to operate more efficiently, flexibly and competitively. Digitalisation plays an important role in this, but many companies struggle with how best to tackle this transformation. Why is that? And how to move forward? We're here to help find a path towards digital maturity.