Start your Tecnomatix Plant Simulation Trial

Model, simulate, explore and optimise logistics systems and their processes.

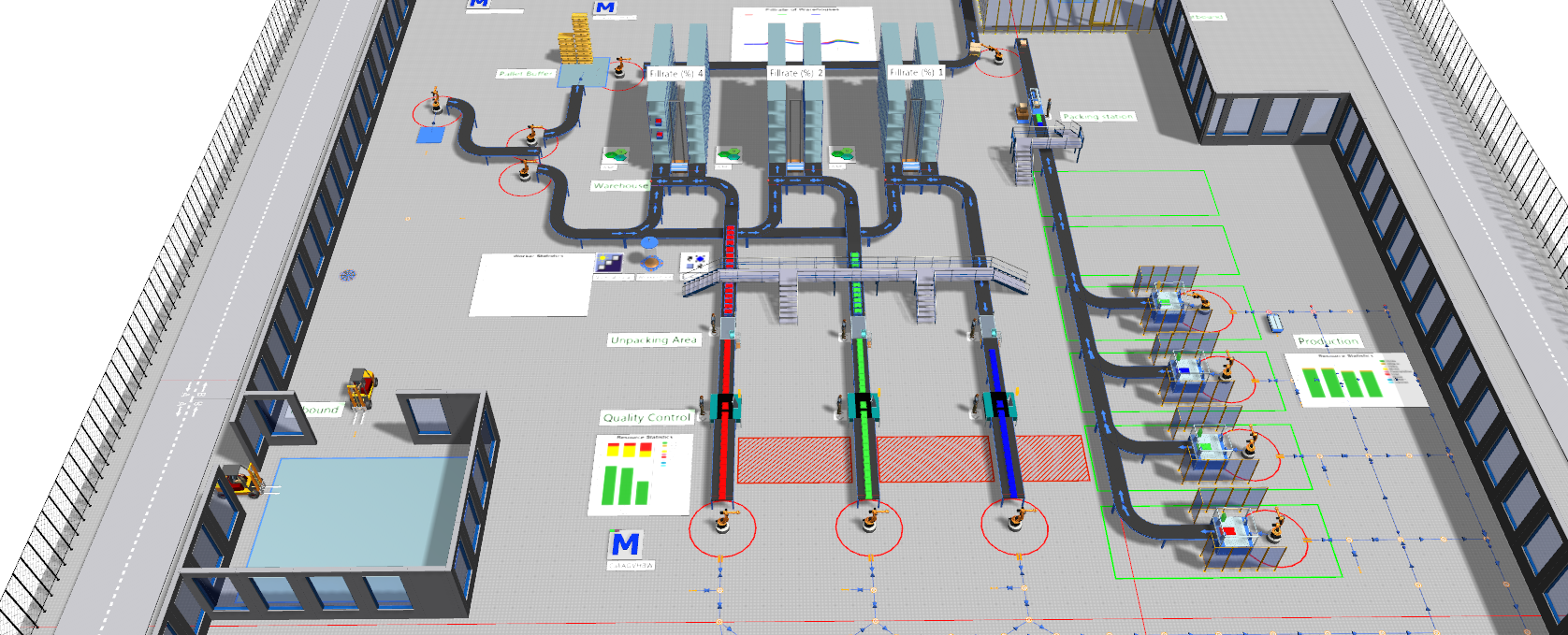

These models enable analysis of material flow, resource utilisation and logistics for all levels of manufacturing planning from global production facilities to local plants and specific lines, well in advance of production execution.

Understanding and planning how logistic systems operate is an essential part of optimising operations and material flow within a business.

/BD-Logo-White.png)

/DAF-Logo-White.png)

/Kornelis-Logo-White.png)

/Mr.Mallo-Logo-White.png)

/P%26G-Logo-White.png)

/UPS-Logo-White.png)

Manufacturers face growing challenges: multi-site operations, supply disruptions, & demand for sustainable, customised products that can strain capacity and delay delivery.

Accelerate time-to-market by virtually validating processes early. Use 3D simulation to optimise & commission workflows, improving efficiency and quality. We present two modern digital manufacturing solutions:

Manufacturers face growing pressures, supply chain disruptions, multi-site operations, and rising demand for customised, sustainable products. These challenges strain capacity and lead to delays and cancellations.

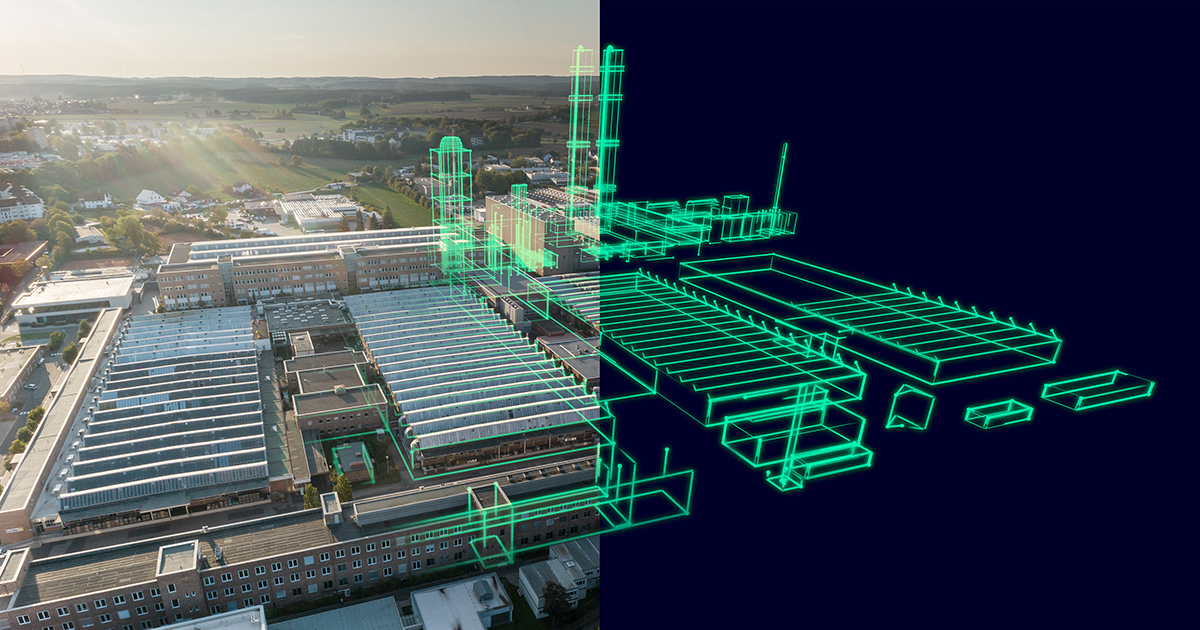

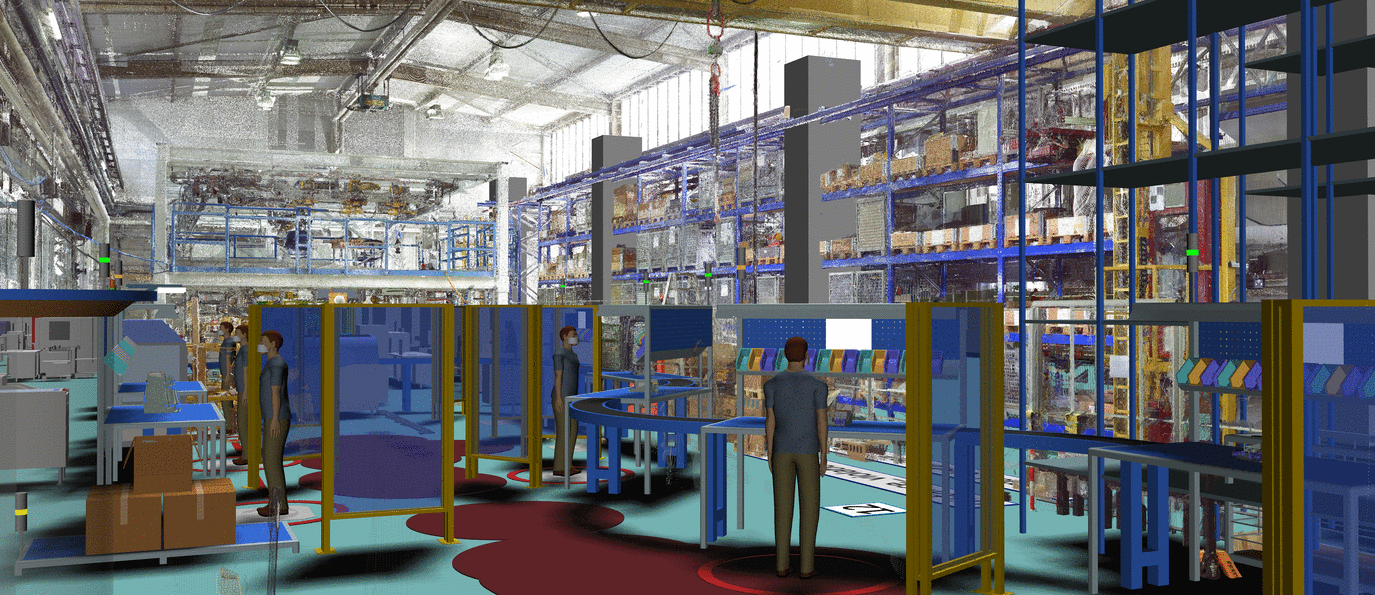

Stay competitive by digitally validating logistics and production systems early to accelerate time to market. Use 3D models to simulate and optimise complex processes involving materials, equipment, and personnel, enabling faster launches and improved production quality.

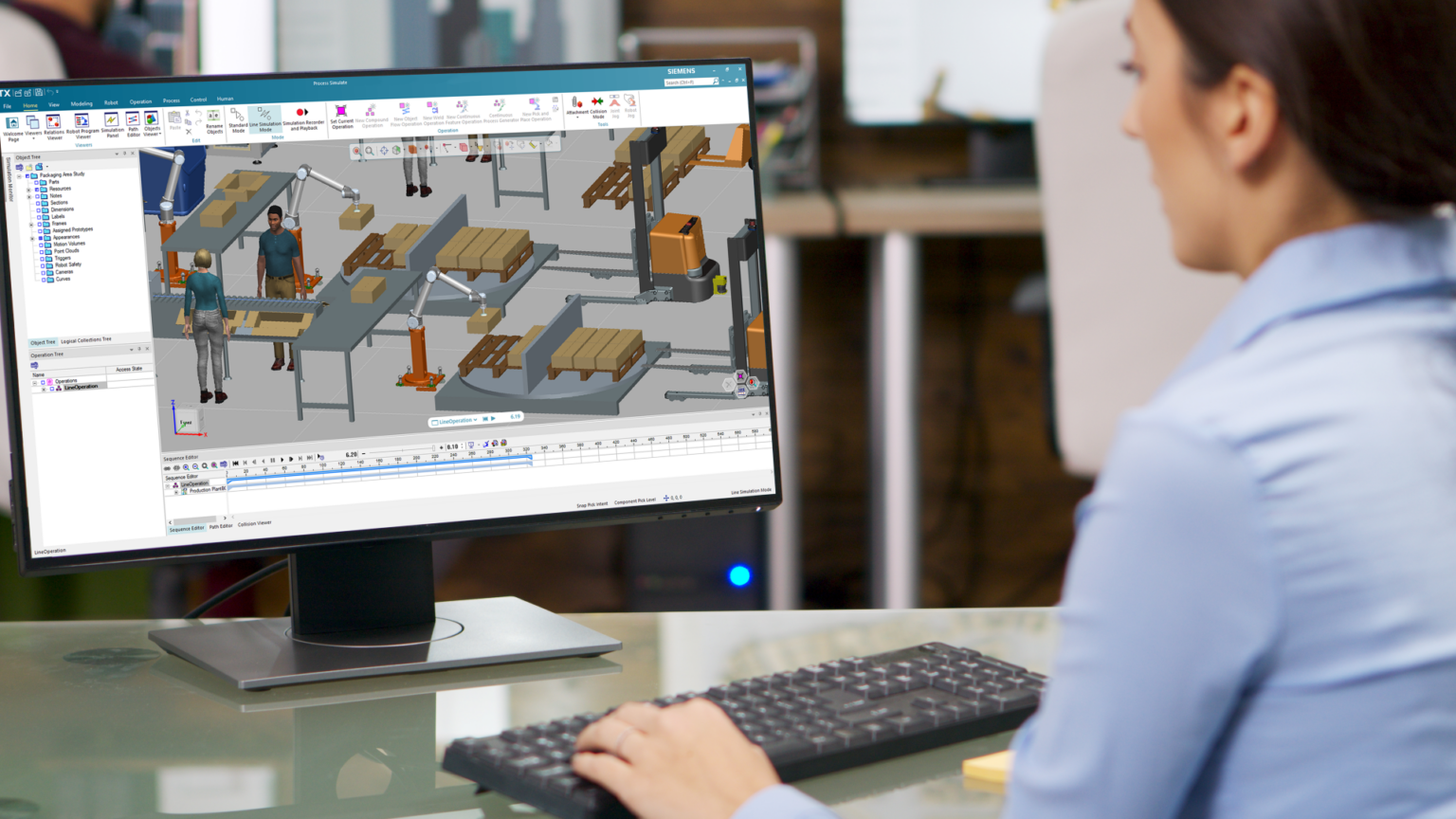

Plant Simulation X is a cloud-based software-as-a-service (SaaS) solution that delivers advanced digital manufacturing capabilities to simulate, analyse, and optimise production and logistics across all planning levels. Work within a 3D environment using hierarchical models of facilities, production lines, and operations, enhanced by the flexibility, security, and scalability of the cloud.

With fast deployment and simplified configuration, you can boost productivity and quickly scale your manufacturing operations. It offers cost-effective, customisable packages designed to meet varying levels of digital manufacturing complexity.

Develop 3D hierarchical models of production facilities, lines, and operations for efficient modelling of discrete and continuous manufacturing processes using a powerful object-oriented architecture and advanced capabilities.

Construct and visualise in 3D with built-in libraries or external CAD data. Leverage the JT format and Siemens' direct model technology for fast loading and realistic rendering of large simulation models, optimised for simulation and analysis.

Efficiently manage and scale complex simulations with Tecnomatix’s object-oriented architecture, leveraging encapsulation, inheritance, and hierarchy to improve model clarity, reusability, and maintainability.

Build models using nested objects and sub-models at any level. Library items are accessible to all users, with updates automatically reflected across instances. These items can also be customised to meet specific needs within individual simulations.

Model, simulate, explore and optimise logistics systems and their processes.

Access numerous built-in tools and graphical outputs to evaluate production system performance, featuring automatic bottleneck detection, throughput analysis, utilisation metrics for machines, resources, and buffers, energy consumption tracking, cost analysis, Sankey diagrams, and Gantt charts.

Utilise experiment management tools and integrated neural networks to facilitate extensive experiment handling and automated optimisation of systems through genetic algorithms.

Take advantage of an open system architecture that facilitates support for multiple interfaces and integration capabilities, such as ActiveX, C, CAD, COM, JSON, MQTT, ODBC, OPCClassic, OPCUA, Oracle SQL, Socket, and XML.

Easily integrate with other Siemens software applications, including NX Line Designer, Teamcenter, Simcenter HEEDS, Opcenter APS, TIA Portal, PLCSIM Advanced, and SIMIT.

This was a great training course, the instructor's style was very good which made the course enjoyable.

With a focus on specialisation and innovation in marshmallow manufacturing, they produce approximately 14,000 tons of high-quality marshmallows annually. Operating from three facilities in Belgium and Spain, Mr. Mallo offers a variety of recipes and packaging options.

Paulaner Brewery now produces around 2.4 million barrels, nearly 74 million gallons, of beer each year. It is one of six breweries that supply beer for Oktoberfest, the iconic German festival established in 1810.

"With the good visualization possibilities of Tecnomatix, I can show the management an early stage of planning that makes the processes plausible."

Bernd Ebert, Director of Global Manufacturing Engineering − Food Preparation, Electrolux

Together we build the foundation of your business growth using Tecnomatix.

Tecnomatix Plant Simulation is an advanced discrete-event simulation software created by Siemens. It allows users to model, visualise, analyse, and optimise production systems and logistics processes. By developing digital twins of manufacturing facilities, you can pinpoint bottlenecks, optimise material flow, and improve resource utilisation, ultimately resulting in increased efficiency and lowered operational expenses.

Certainly. Tecnomatix Plant Simulation is tailored to model a wide range of systems, from straightforward production lines to complex manufacturing networks. Its hierarchical modelling capability allows you to decompose intricate systems into manageable segments, enabling more detailed analysis and optimisation.

Yes, Tecnomatix Plant Simulation supports integration with various CAD and Product Lifecycle Management (PLM) systems. This functionality facilitates smooth data transfer, enabling you to import existing designs and layouts into your simulation models, which enhances accuracy and minimises modelling time.

Yes, Tecnomatix Plant Simulation includes robust 3D visualisation capabilities that allow you to create realistic depictions of your production systems. This feature aids in comprehending and communicating the dynamics of your manufacturing processes, thereby supporting effective decision-making and stakeholder engagement.

You can buy Tecnomatix Plant Simulation by reaching out to us directly, either through filling out the form on this page, emailing us or calling us. We are here to support you in exploring licensing options, arranging a personalised demonstration, or accessing a trial version, allowing your team to engage with Tecnomatix Plant Simulation directly. Additionally, we provide training and support to ensure a seamless implementation.

Tecnomatix Plant Simulation is highly versatile and applicable to a variety of industries, such as automotive, aerospace, electronics, consumer goods, logistics and many more. Any sector that deals with complex manufacturing processes and aims to optimise production efficiency can greatly benefit from the adoption of this simulation tool.

Tecnomatix Plant Simulation is an advanced discrete-event simulation software created by Siemens. It allows users to model, visualise, analyse, and optimise production systems and logistics processes. By developing digital twins of manufacturing facilities, you can pinpoint bottlenecks, optimise material flow, and improve resource utilisation, ultimately resulting in increased efficiency and lowered operational expenses.

Certainly. Tecnomatix Plant Simulation is tailored to model a wide range of systems, from straightforward production lines to complex manufacturing networks. Its hierarchical modelling capability allows you to decompose intricate systems into manageable segments, enabling more detailed analysis and optimisation.

Yes, Tecnomatix Plant Simulation supports integration with various CAD and Product Lifecycle Management (PLM) systems. This functionality facilitates smooth data transfer, enabling you to import existing designs and layouts into your simulation models, which enhances accuracy and minimises modelling time.

Yes, Tecnomatix Plant Simulation includes robust 3D visualisation capabilities that allow you to create realistic depictions of your production systems. This feature aids in comprehending and communicating the dynamics of your manufacturing processes, thereby supporting effective decision-making and stakeholder engagement.

You can buy Tecnomatix Plant Simulation by reaching out to us directly, either through filling out the form on this page, emailing us or calling us. We are here to support you in exploring licensing options, arranging a personalised demonstration, or accessing a trial version, allowing your team to engage with Tecnomatix Plant Simulation directly. Additionally, we provide training and support to ensure a seamless implementation.

Tecnomatix Plant Simulation is highly versatile and applicable to a variety of industries, such as automotive, aerospace, electronics, consumer goods, logistics and many more. Any sector that deals with complex manufacturing processes and aims to optimise production efficiency can greatly benefit from the adoption of this simulation tool.