News & Blogs

Stay updated with the latest news, insights, and expert blogs from Emixa. Explore industry trends, digital innovations, and company updates all in one place.

- Siemens

- NX Design

- +2

What’s New in Siemens NX – Release 2506

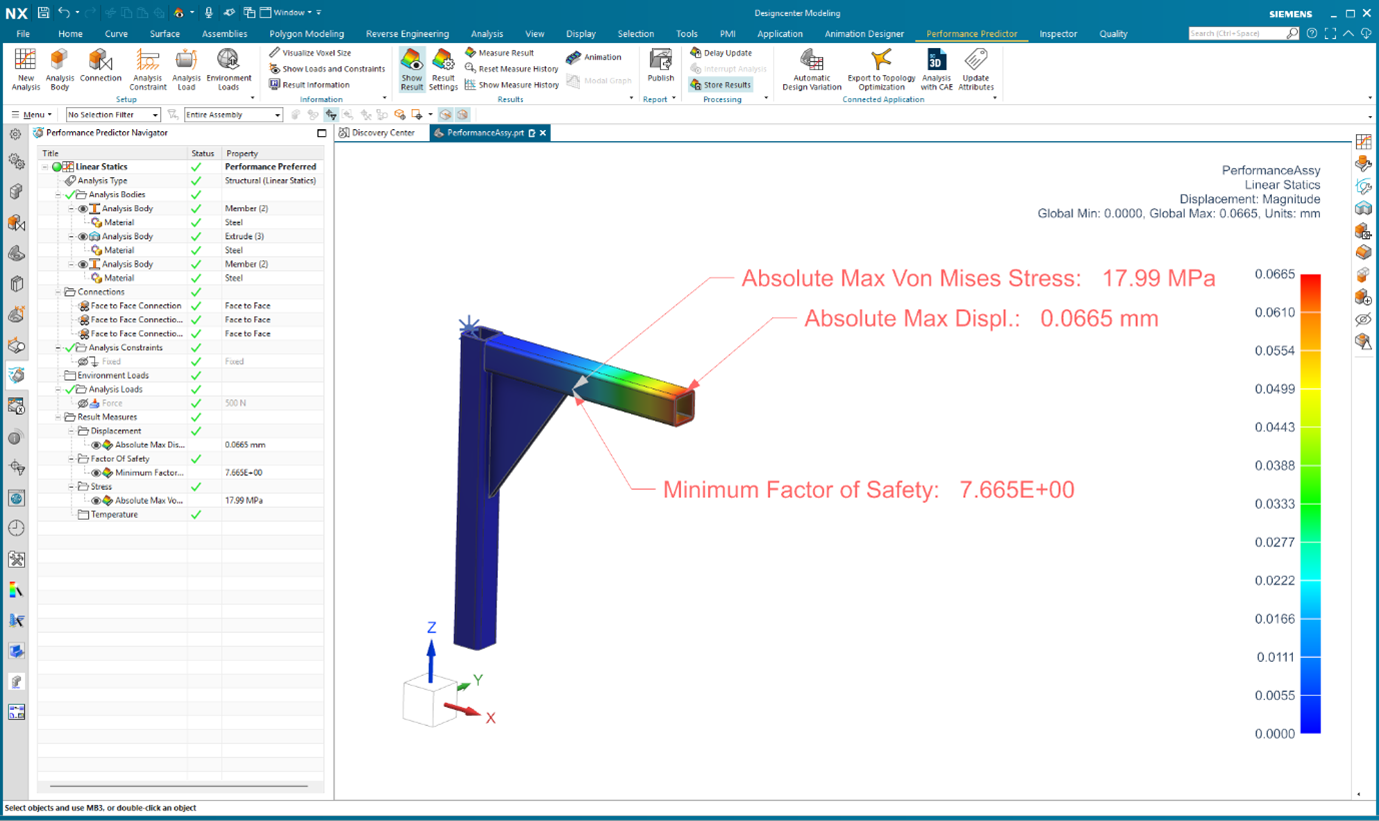

What’s New in Siemens NX – Release 2506 In June, Siemens released the latest version of NX, officially designated as version 2506. During this Webinar, Ruud van den Brand (Emixa Industry Solutions) and Bas Verschuren (Siemens) guide participants step by step through the innovations in this release. Their main message? Siemens NX is becoming broader, smarter and more flexible, not only from a technical perspective, but also in terms of user experience and licence management. A New Name: Designcenter NX NX is no longer positioned simply as “NX”, but more broadly under the name Designcenter NX. This is more than a cosmetic change. Siemens is bringing NX together with other tools such as Teamcenter, Simcenter and Tecnomatix under the umbrella of the Xccelerator platform. Their message was clear: one integrated environment for design, simulation and manufacturing, from browser to desktop. There is now an ‘Essentials’ edition: a browser-based version of NX that enables direct work in the Cloud. This is particularly useful for quick edits or in environments where flexibility is critical, all without compromising compatibility with the desktop version. User Friendliness First: Improvements in the User Interface NX has once again become smarter in terms of interface. A subtle but valuable addition is the sensitivity slider in the Select Similar Edge/Face function, allowing more precise control over what is recognised as ‘similar’. This makes it faster to adjust or group multiple elements.

- Manufacturing

- Mendix

- +2

Maximise production with Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is a common Key Performance Indicator within industry, which compares actual production output with the maximum capacity of production processes.

- Manufacturing

Event Recap: Exploring the Future of Manufacturing, May 22nd 2024

Unveiling the Future if Manufacturing at Siemens Digital Experience Center.

- Manufacturing

- Digital Twin

The Adoption of Digital Twins in Manufacturing

In the relentless pursuit of operational excellence and superior product quality, the manufacturing industry finds itself at the threshold of a technological revolution. At the forefront of this transformation is the adoption of ‘digital twins’, a concept that promises not only to enhance operational efficiency but also to redefine competitive strategies. This article delves into the emergence of digital twins, tracing their historical roots and exploring their potential to bolster the manufacturing sector's competitiveness.

- Manufacturing

Event Recap: Revolutionize Manufacturing on November 23, 2023

An Innovative Journey at Siemens: Diving into the Future of Manufacturing!

- Manufacturing

How to Achieve Collaboration in the Supply Chain

The days when machine builders had to invent, develop and build everything themselves are long gone. Most modern companies have their own suppliers or are part of the supply chain of an OEM. This cooperation between Dutch manufacturing companies is of course very nice, but it also brings major challenges to the table. One of the most important ones? Finding out how to deal with the crucial data exchange that fosters seamless collaboration throughout the supply chain. Every manufacturing company, regardless of its core business and the industry to which it belongs, feels the increasing pressure of competition, decreasing margins, rising costs and staff shortages. To bring products to market quickly and without error, manufacturing companies can no longer afford to lose time on cumbersome, error-prone and manually-driven data exchange processes. The need for automation and smarter processes rises with increasing product complexity and creates a growing number of challenges. First of all, companies must deal with more and more complex data. Assemblies are getting bigger, whilst the number of electronic components, specifications and quality controls is on the rise. In addition, each company applies its own, often unique working methods and uses different tools and modes of operation when it comes to storing, supplying and structuring data. Standardisation is lacking, since companies usually do not have access to each other's systems. So how do you ensure data exchange between supply chain partners without being exposed to a cyber attack?

- Manufacturing

- Data Analytics

Generative AI in Engineering: Transforming Services and Innovation

This innovative process engineering company specialises in the end-to-end delivery of processing systems. Its services range from the design of bespoke machines to its installation onsite to various maintenance services. The company is always on the lookout to improve its services. How can it improve its troubleshooting and maintenance activities and offer added value for clients?