News & Blogs

Stay updated with the latest news, insights, and expert blogs from Emixa. Explore industry trends, digital innovations, and company updates all in one place.

- Industry 4.0

- Industrial Internet of Things

What is Industrial Internet of Things (IIoT)?

The Industrial Internet of Things (IIoT) is an advanced application of IoT technology designed specifically for the industry. In the context of Industry 4.0, the fourth industrial revolution, IIoT plays a crucial role. It enables the integration of physical and digital systems, resulting in smart factories. These factories offer personalised production processes and smooth cooperation between humans and machines. This allows companies to operate more flexibly and respond better to changing market needs.

- Applications

- Mendix

How Autohopper Significantly Improved Their Mendix Application

Autohopper is the straightforward car rental service in the Netherlands. If you need to rent a car or a van, Autohopper has you covered. With over 100 locations, Autohopper is the car rental service with the most extensive network in the Netherlands. To manage their services effectively, they utilize a Mendix application. The existing application received a rating of 2 from Autohopper's franchisees, prompting them to engage Emixa to optimize the app.

- PLM

The Digital Machine Shop: The Road to Shorter Production Times

The Digital Machine Shop helps companies stay competitive, design the right products, and find the best way to manufacture them. This data-driven environment transforms production and the business by seamlessly connecting all elements of your operations, such as processes, machines, robots, and people. This model includes a fully digitised, faster production process - ranging from preparation to the final manufacturing of products or components. A model that can be used in all industries including aerospace, medical devices, and industrial machinery manufacturing. The Digital Machine Shop includes two processes: the manufacturing process and the inspection process. A component model designed in CAD software is the starting point for executing these processes. In the first step of the manufacturing process, preparations are made to turn the component model into a milled product. This involves looking at positioning, material use, and the steps to be performed. This is the preparatory phase for step two: programming the milling paths. In this step, a milling programme is created by CAM software through different operations. This NC programming provides the basis for controlling the machine. To prevent errors and to set up the milling process in an optimal way, the milling paths are simulated. A 3D simulation sets the machine in motion virtually to predict the milling process and detect and resolve errors early. At the same time as implementing the Digital Machine Shop method, the measurement process starts. In this stage, a virtual measurement takes place, which can be performed using CMM software that controls the automated measuring machine. A measurement plan is created with the help of PMI data to formulate the necessary measurement values. The probe path of this measurement plan is then programmed as the next phase in the process. To check the feasibility of this probe path, it is virtually set in motion by 3D simulation and adjusted where necessary. Benefits of the Digital Machine Shop: Increased machine utilisation Reduced machine cycle time Faster set-up Precision Machining Improved quality inspections Enables more complex products Innovative technologies New business models In the Digital Machine Shop, Siemens software ensures seamless information flow throughout the entire production process, eliminating the need for transitions between different software systems. Any changes made at the start of the process can easily and quickly be implemented in the final step. Using the same model for the production process ensures faster and more effective operations. If you have a machine shop, you know production time is crucial. Digital automation of production achieves first-time-right to shorten throughput time and accelerate time-to-market. If you aim to optimise and accelerate your production process, the Digital Machine Shop is your ideal starting point! Would you like to learn more on this topic? Download the eBook on the roadmap to a Digital Machine Shop or watch our webinar on getting more out of your current machinery!

- PLM

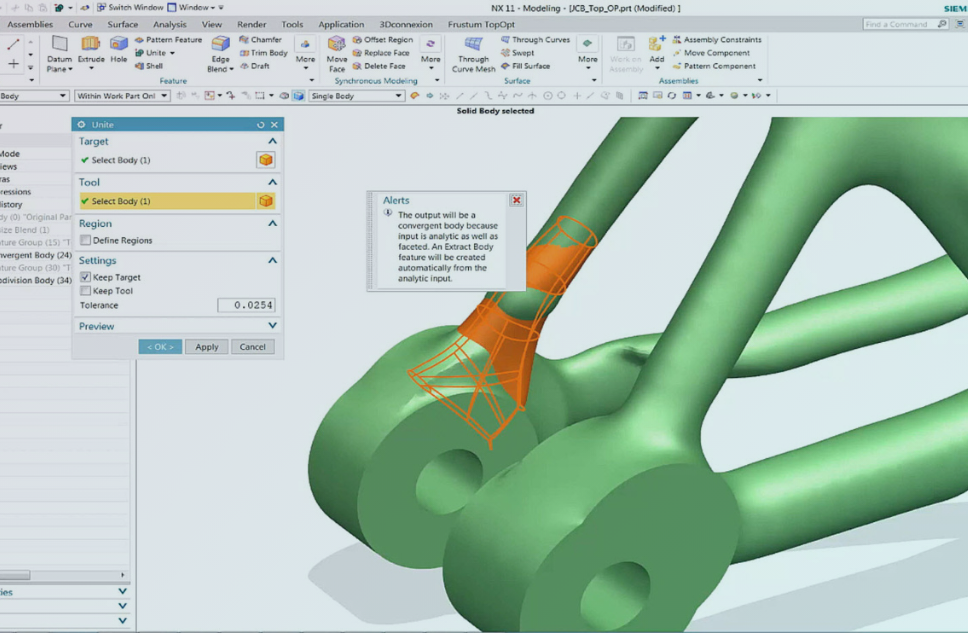

Reap all the Benefits of Additive Manufacturing

Companies are challenged every day by their customers with requests for more complex products, in smaller batches, with shorter lead times and at lower prices. An almost impossible ask, but if your competitor can deliver, you can't fall behind. Innovative technologies like Additive Manufacturing (AM) can improve and streamline your processes. When used correctly, AM offers numerous advantages over conventional production technologies. It brings about a revolutionary shift in the way we manufacture parts across various industries, catering not only to big businesses but also to small and medium enterprises. Additive Manufacturing in the product lifecycle Additive Manufacturing, also called 3D printing, has existed for over 35 years. But considering we've used conventional tech like subtractive and forming processes for thousands of years, you could say we've only just begun tapping into AM's potential. Starting in the '80s as a rapid prototyping tech, it's now increasingly used across the product lifecycle. Diverse applications need different materials and processes. Luckily nowadays there are printers that easily switch materials, vastly expanding possibilities. With professional, affordable desktop 3D printers you can print most of your prototyping and tooling applications quickly, cheaply and in-house. For some applications, it's even possible to print end-use parts or spares. Prototype 3D print your visual and functional prototypes to detect issues earlier, test new features and cut down time-to-market. Tooling Through the printing of production tooling, the ability to craft custom tools becomes a faster, more cost-effective, and in-house possibility. But the real value lies in the impact these custom tools can have on your processes, making them more efficient, rapid and safe. Production part Using 3D printing as a production technology to manufacture end-use parts makes it possible to create components that would be impossible with conventional manufacturing methods. Spare parts By 3D printing your spare parts on-demand, you can reduce inventory, storage space, and waste. Combining this with on-site printing also lowers transportation and packaging costs. Benefits of Siemens NX™ Additive Manufacturing Greater design freedom Customisation, enabling lot size 1 Utilisation of only essential materials Part consolidation and function integration Enhanced performance Metamaterials Print "on-demand" and "on-location" Industrial Additive Manufacturing For advanced applications, industrial 3D printers are sometimes the best solution due to specific material needs, build volume, capacity or resolution. An increasing number of companies successfully print a wide range of apps across sectors. But AM isn't a standalone process - upstream and downstream procedures must be considered too. Design for Additive Manufacturing (DFAM) Every production process has design rules and tools. As "Additive" is the very opposite of conventional "subtractive" manufacturing, traditional design tools don't always give the needed results. You don't remove material from a block, only adding it where necessary. That's why Siemens NX developers have added new design capabilities in recent years, helping designers fully harness AM's potential. AM Build Preparation & Simulation In 3D printing, the orientation of a part in the printer plays a crucial role, affecting strength, quality, costs, print times, material usage, and post-processing. Siemens NX's Build Preparation functionality offers orientation guidance, allowing you to save the desired orientation directly in the CAD model, ensuring consistent and repeatable outcomes. CNC Post-Processing Once your metal print is complete, the removal of metal supports is still necessary. Manual removal can be labor-intensive and lacks repeatability. This process can be automated via CNC milling, automatically eliminating supports and ensuring correct dimensions and surface finish. Programming and simulating the milling process can also be done in Siemens NX, preventing collisions and milling issues. Whether you're new or experienced in 3D printing, just exploring its potential or running industrial printers 24/7. We're here to support your business every step of the way to successfully implement Additive Manufacturing.

- IT

Digital Banking Solutions | Argenta Success Case

Emixa will renovate the customer portal of Argenta Netherlands, a bank specializing in mortgages and savings for individuals. Argenta, a Belgian bank with its Dutch branch located next to the Rat Verlegh Stadium in Breda, where we are also based, has been active in the Netherlands for over 24 years.

- Digital Transformation

Technical Business Students Dive into the Digital World at Siemens

Question from Daniel: “What do you think Siemens produces?” Answer from students: “Washing machines.”

- Tecnomatix

How to Cope with (Over)full Warehouses?

Effectively managing (over)full warehouses poses a significant operational challenge. Warehousing inherently involves complexities, and the current trend, particularly in areas like the hinterland of the port of Rotterdam and other strategic logistics hubs, is the accumulation of goods leading to warehouses reaching maximum capacities. This makes it harder to work efficiently and comes with its own set of problems. That raises the question: ‘how to cope with (over)full warehouses?’ This development is partly a consequence of the aftermath of the COVID-19 crisis. During the lockdowns, dining out and in-person shopping were restricted, but online ordering of goods was unrestricted. This resulted in a high demand for various products, causing the logistical system to struggle to meet the demand. Businesses and retailers procured their merchandise well in advance, resulting in the saturation of all distribution centres in the hinterland of major ports and, more recently, inland terminals, with goods ordered ahead of schedule. If current demand and buying confidence were still as robust as during the pandemic, this might not be a major concern. However, the combination of inflation and soaring energy prices has made people more cautious about their spending. As a result, goods are staying in warehouses longer than usual, causing efficiency and optimisation challenges in warehouse management. While companies have limited control over macroeconomic factors, they can secure a competitive edge by concentrating on optimisations in their warehouse layout and/or operational methods, enhancing the flow of goods within their warehouses. Read on to find out how to cope with (over)full warehouses and the role Emixa can play in improving processes in warehouses. Practical problems in coping with (over)full warehouses The accumulation of goods confronts warehouses with various practical problems. Many warehouses do not actually earn their money through storage itself, but above all by repacking, labelling and distributing goods. As a result, any lack of turnover and the steady accumulation of products in the warehouse threatens their business model and profitability. Moreover, there are negative consequences for daily operations within the workplace. For example, warehouse utilisation of 90 to 98 percent means that warehouse teams are less efficient. Forklifts are required to lift goods to greater heights, and numerous products are positioned in challenging or harder-to-reach spots outside the racks. The result is that pickers and forklift operators need to cover more distance, resulting in less efficient routing and delays, further prolonging the storage of goods. Locating and gathering the correct items also becomes more challenging, contributing to delays in deliveries. Ultimately, there's a risk at the end of the chain where retailers may need to discard products that have been sitting on the shelves for too long. The aforementioned issues not only compromise efficiency but also have negative effects on employees. They find themselves working overtime more frequently and with less enjoyment. The likelihood of fatigue and overburdening increases, resulting in additional costs and staff shortages. Finding sufficient personnel is already challenging in the current tight labour market. In summary, no one benefits from an excessively high fill rate in the warehouse. The digital twin Evaluating potential solutions to enhance operational efficiency in a warehouse carries inherent risks. The proposed idea may succeed, fail, or require multiple attempts before achieving the desired outcome. Regardless of the result, these attempts consume valuable time. Utilising advanced simulation software mitigates these risks. A realistic, interactive digital twin of your warehouse allows for the virtual testing of ideas and scenarios in a digital replica. This well-established technology, initially used for virtualising production lines and entire factory setups, has been extended to optimise warehouses due to the close connection between production and logistics. Years ago, we applied this expertise to enhance warehouse efficiency. Altering walking or driving routes to improve the efficiency of pickers and expedite order completion? Changing the warehouse layout and pathways to facilitate easy access for forklifts to pallets and boxes? Optimising the existing space? With plant simulation, you can virtually experiment and compare multiple options, scenarios, and warehouse layouts. This way, you can quickly determine the most efficient working method. How Emixa can help Emixa can assist companies with warehouse management and optimisation. “Using the ‘digital twin’, true-to-life, complex simulations are possible. This enables our clients to maximise efficiency from their warehouse capacity,” explains Nick Peeters, PlantSim Expert at Emixa. “The expertise of Emixa in both the manufacturing and logistics/warehousing sectors, combined with our in-depth knowledge of the Mendix platform for developing specialist low-code applications for logistics and warehousing, make Emixa Industry Solutions and Emixa Applications Solutions a very valuable partner for our clients,” says Ruben van der Leer, Account Executive at Emixa Applications Solutions. “Thanks to low-code and integration, you can achieve a level of efficiency that would not have been possible a few years ago.” Most warehouses work with automation from various suppliers and a wide variety of partners within the logistics chain. The solutions and knowledge of Emixa Industry Solutions ensure that all those different cogs are represented in one system. In this way, they produce a dynamic layout of your logistics system, providing insight into the entire system. Because many logistics companies need to allow for growth in capacity, maintaining oversight is the most important thing. By tuning the performance of subsystems to one another, you avoid suppliers and partners sending you from pillar to post. One of Emixa Industry Solutions’ specialities is simulating warehouses and the systems they use. By simulating systems, potential improvements and different scenarios and solutions over time, your organisation can instruct employees and partners in detail to implement the necessary optimisations. Want to learn more about managing (over)full warehouses? For a smooth flow of goods, warehouses are partially reliant on economic factors beyond their control. Nevertheless, a well-designed, modern, and flexible simulation and optimisation system provides more opportunities to maintain service levels, control fill rates, and streamline warehouse processes efficiently. But it all begins with insight. Curious how Siemens & Mendix solutions, combined with our expertise, can support you in this matter? Please feel free to contact us for more information and expert advice.

- Mendix

Manufacturing Menu: Optimize Resources and Performance with Top Tools

Manufacturing companies operate in a challenging and dynamic marketplace. They face volatile prices, fluctuating raw material availability and increasingly complex supply chains. In addition, reducing waste is high on the sustainability agenda, and finding enough skilled workers in a tight technical labour market is no easy task. To strike the right balance between resource utilization, cost optimization and supply chain optimization, optimal performance and efficient utilization of the production environment is essential. By improving the utilization of your factory and the performance of your equipment, you can increase productivity, improve job satisfaction and optimize collaboration throughout the production and supply chain. This is why this part of a manufacturing company's operations has a prominent place in Emixa's Manufacturing Menu.

- Industry 4.0

Is your Company Making a Difference with Model-Based Definition?

Digitisation is progressing rapidly everywhere. Manufacturing companies also face this challenge now more than ever. To be digital, or not to be. In the shift to digital, traditional 2D drawings are giving way to Model-Based Definition (MBD). Has your company made the essential move towards Industry 4.0?