News & Blogs

Stay updated with the latest news, insights, and expert blogs from Emixa. Explore industry trends, digital innovations, and company updates all in one place.

- Plant Simulation

Transforming from Static Blueprints to a Dynamic Digital Factory

Van Wijnen is a Dutch company in the construction sector, committed to environmentally friendly building for the next generation. Operating from 25 locations across The Netherlands, Van Wijnen is involved in the development, construction, management, and maintenance of buildings and homes. With the high demand for housing in The Netherlands and a shortage of affordable homes, Van Wijnen recognises the need for a different approach to construction. The scarcity of skilled workers in the industry further intensifies the challenges in housing construction. To address these issues, Van Wijnen is increasingly focusing on industrialised construction, aiming for faster, more cost-effective, cleaner, and circular building methods. A digital production process To meet the high demand for housing in the coming years, a substantial number of homes need to be built. Van Wijnen's goal is to realise 4,000 homes per year in the upcoming years. To achieve this, Van Wijnen has invested in a dynamic (or in other words: digital) design, development, and production process. This digital production process takes shape in a greenfield housing factory. In this future factory, there are large steel tables on which a mould is built using a robot. By using a high degree of robotisation, the problem of skilled worker shortages in construction is also partially solved. The tables with moulds move like a carousel through the factory. At each point where the table stops, value is added, such as reinforcement steel, electrical boxes, window frames and structural lifting and coupling facilities. After adding all the components, concrete is poured, and elements like walls, facades, or floors are prepared. These elements are then put in a controlled environment to cure, all part of an automated process. On-site teams later assemble these components, maintaining a rapid pace, completing one home or two flats each day. This automated process, with its scale and variety, ranging from ground-based homes to flats and gallery flats, all produced in a single housing factory, stands out as unique in the construction industry, not just in the Netherlands but beyond. The added value of simulation Simulation serves a crucial role in assessing the viability of an automated process designed to manufacture prefabricated elements for 4,000 homes per year. By transforming the initial static layout drawing into a dynamic scale model, different scenarios can be evaluated. Siemens Tecnomatix Plant Simulation allows Van Wijnen to analyse the manufacturing facility's capability to produce a significant number of components within the desired timeframe. This simulation involves replicating the plant, production floor, machinery, and personnel to examine and validate production changeover times. With various machines assigned different tasks, aligning them seamlessly becomes essential. This software empowers Van Wijnen to optimise machine configurations successfully, ensuring the achievement of the goal to manufacture 4,000 homes each year. "Through our simulations, we gained early insights into the optimal machinery layout. The dynamic factory simulation helps uncover potential errors, allowing for early identification and resolution of bottlenecks. This not only instils confidence but also offers the flexibility to test optimisations cost-effectively." - André Klouwen, Deputy Director of Technology at Van Wijnen Components Save costs and maintain oversight An increasing number of companies establishing a greenfield production facility opt to simulate a dynamic version of the future factory or production hall before its physical construction. The ability to foresee and test the flow of your factory in advance, ensuring that your machinery and desired production can be realised. Knowing the required number of operators to achieve the projected and determined production levels. Despite the complexity of the process, Siemens Tecnomatix Plant Simulation can preserve clarity and save costs. We are very proud to be part of the future of living! While prefabricated homes have been around for some time, they haven't been produced at this volume. Tecnomatix Plant Simulation is the solution for intricate processes, transitioning from static drawings to a dynamic, digital version of your factory! Would you like to get started with a simulation of your production environment? Contact us directly.

- Mendix

Manufacturing Menu: Boost Marketing & Sales with Mendix Dealer Portal

What is the secret of B2B marketing and sales in the digital age? Personalization and strong engagement with your dealers. This is achieved by having a good understanding of their needs and wishes and establishing powerful integration between all your communication and sales channels. Building and actively using a dealer portal is a great solution for manufacturing companies and B2B sellers to boost their marketing and sales activities. But what can you do with a dealer portal? And what are the benefits? We'll tell you in this article and show how the combined knowledge and experience of the companies within Emixa help in developing a modern, versatile and future-proof dealer platform.

- Applications

- Mendix

A Fully Automated Exam Flow with EMO

In collaboration with Emixa, Examenadviesburo developed the application EMO, a solution that streamlines the entire exam flow. We spoke with General Director Anne Prins-van den Bergh about the development process, the collaboration with Emixa, and the benefits of the new system.

- Manufacturing

- Mendix

- +2

Maximise production with Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is a common Key Performance Indicator within industry, which compares actual production output with the maximum capacity of production processes.

- PLM

Coherent Project Documentation with Polarion

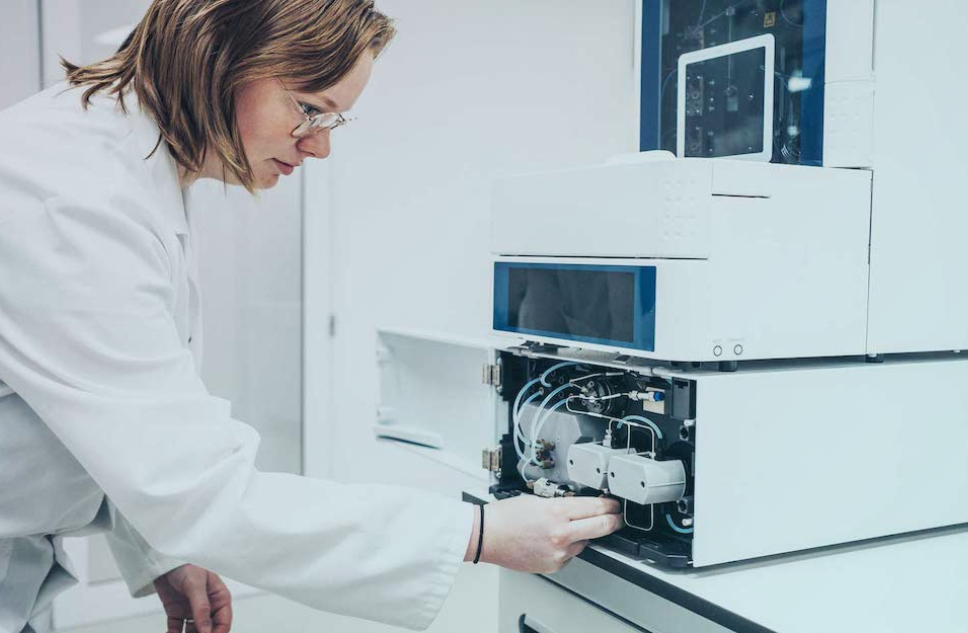

Spark Holland is a supplier of innovative sample introduction, extraction, and separation technology for analytical systems such as HPLC, MS, GC, and NMR. Spark gathers user feedback and seeks to understand typical issues in the analytical laboratory, focusing on product development towards simplicity and reliability. To create products that prioritise simplicity and reliability, it's essential to use a user-friendly, open, and easily understandable tool for requirement management. Shifting away from disjointed documents and spreadsheets, which previously formed the foundation of requirements management, became a challenge as projects grew more complex, making traceability nearly impossible. In a proof of concept, Polarion not only addressed the traceability issue immediately but also led the team to reevaluate the development process, resulting in a simplification step. Polarion Application Lifecycle Management enables teams to collaborate easily and securely on shared documentation. You can define who can see what, who can make changes, and when, through detailed permissions and robust configurable workflow automation. Additionally, Polarion has an FDA-approved electronic signature process. "Emixa Industry Solutions has consistently demonstrated expertise and reliability in addressing our Product Lifecycle Management needs over the years. Including them in our shortlist of vendors was a logical choice due to their knowledge and ability to meet customer requirements precisely. Their extensive partner network enables them to address any gaps in demand." - Nils Reuvers, IT Manager at Spark Holland B.V. The implementation of Polarion has resulted in more streamlined, improved, and cohesive project documentation with comprehensive, readily accessible traceability, all while minimising administrative overhead. Polarion has facilitated easier compliance with legal standards and regulations, creating clarity and improving the working process within product development. Want to learn more about this? Contact us.

- Boomi

- ERP Software

SPIE Netherlands Discovers the Benefits of Boomi

Both large enterprises and SMEs nowadays increasingly use smart applications to manage and improve their business processes. These applications also need to communicate with existing (on-premises) systems. Establishing such integration can be a significant challenge. Boomi provides a solution, helping to quickly and easily connect all applications and system components. One company that has discovered the benefits of Boomi is SPIE Netherlands. We spoke with Ad van Oorschot, project manager at SPIE Netherlands, about the implementation of Boomi and the collaboration with Emixa.

- Mendix

Manufacturing Menu: Ensuring Safety & Health with the Right Technology

We live in an era where corporate social responsibility (CSR) holds a prominent place on the priority lists of companies and regulatory bodies within the manufacturing industry. As requirements become increasingly stringent and expectations higher, safety, health, and environmental consciousness collectively form a key ingredient of Emixa's Manufacturing Menu.

- IT

- IT Strategy

- +1

Time for a Spring Cleaning? How to Make Your IT Smarter and More Secure

Does this sound familiar? Over the years, your IT landscape has mushroomed, but now you’ve lost track of what’s in place. You discover duplicate licences, underused applications, complex customisations, and systems that don’t integrate well. Meanwhile, costs and frustrations keep piling up. Many organisations struggle with unchecked growth in IT due to a lack of a clear IT strategy. This leads to inefficiencies, unnecessary expenses, and even security risks. It’s time for a spring cleaning!

- ERP Software

Emixa helps GVB on its journey towards data-driven maintenance

Consultancy.nl, the platform for the consulting industry, published an article about our work for Amsterdam's public transport company GVB. How did we support GVB in getting ready for a data-driven future?