Our Approach: How Emixa Delivers PdM

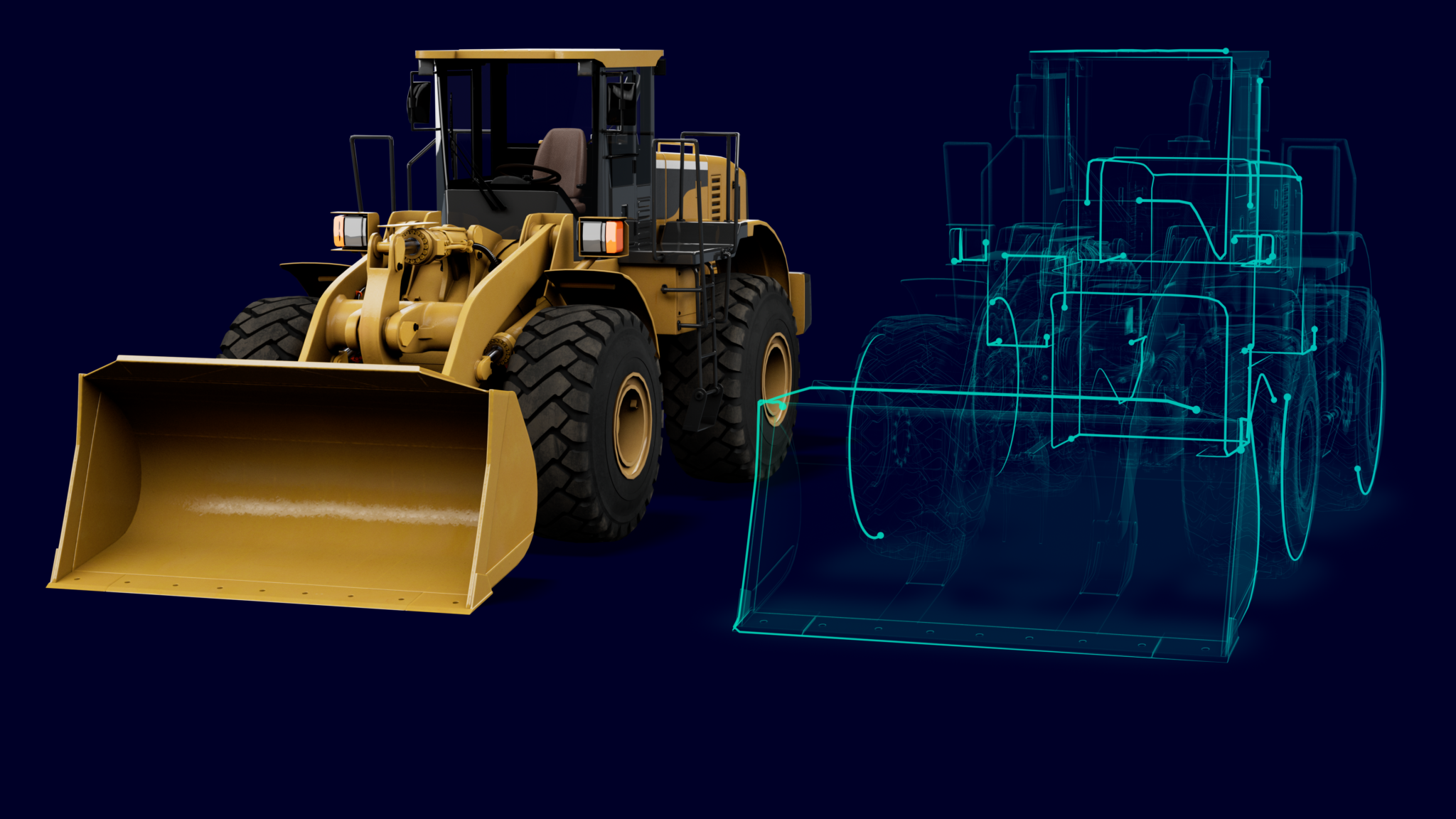

At Emixa, we believe Predictive Maintenance is only successful when it aligns with your organisation's practice. That is why we do not approach it as an off-the-shelf product but as an integral change within your maintenance strategy.

We start with a thorough analysis of your processes, risks and opportunities. Based on this, we develop a clear roadmap in which technological and organisational elements come together. Manufacturing Exceution System (MES) plays a key role here: it connects the production floor with your data and enables real-time adjustments.

We ensure the right combination of sensors, data infrastructure and analytics solutions fully tailored to your environment. And we ensure your team is brought along, trained and engaged, so that Predictive Maintenance truly becomes part of daily operations. Together, we build a maintenance strategy that not only works technically but is also embraced by the organisation.

/Aesseal-Logo-White.png)

/BAE-Systems-Logo-White.png)

/Saint-Gobain-Logo-White.svg.png)