Manufacturing Menu: Smart Solutions for Future Warehouse Management

Last edited on Sep, 26 2024 08:41:05 AM

Reading time: 6 minutes

Written by Minke van Dooremalen | Marketing Manager

Table of contents

In the dynamic world of logistics and warehouse management, companies face the challenge of adapting to a rapidly evolving environment. With the growth of

e-commerce and increasing customer demands regarding delivery times, the traditional Warehouse Management System (WMS) often falls short. The need for innovation and a quick transition to intelligent warehouses is reinforced by factors such as rising labor costs, new government regulations (related to the environment), and disruptions such as pandemics.

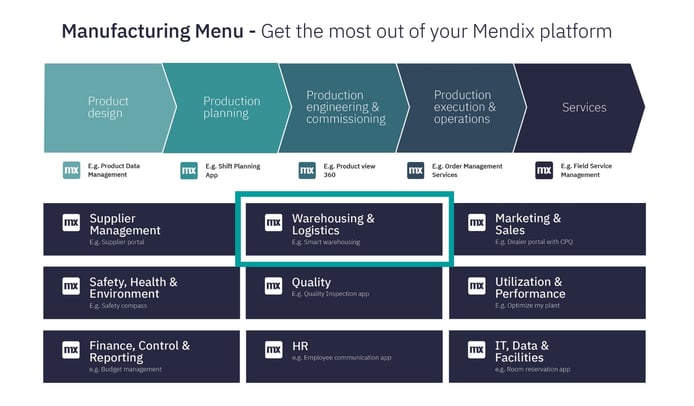

A future-proof warehouse is flexible, scalable, agile, and responsive. Smart Warehousing is a collective term for a range of intelligent systems and techniques that optimize warehouse processes. It goes beyond the traditional functions of warehousing and includes the use of automated systems that are becoming increasingly independent. Hence, this aspect of the operations of manufacturing companies occupies a prominent place in the Manufacturing Menu of Emixa.

About the Manufacturing Menu

The Manufacturing Menu focuses on all production phases and domains within manufacturing companies, addressing specific challenges. It provides practical solutions to promote agility, innovation, and adaptability through Mendix's low-code. In this blog post, we delve deeper into the world of Warehouse Management.

This blog is part of the series: "Manufacturing Menu: Practical Solutions for the Manufacturing Industry". If you are also interested in the benefits of an effective supplier portal and how it can contribute to smoothly managing various tasks and processes related to supplier management, we invite you to read this blog as well. Discover more here.

Efficient and Smarter Work through Smart Warehousing

The answer to the significant challenges in logistics and warehouse management? Smart Warehousing! This approach uses techniques such as digital twinning and plant simulation. With a truthful, interactive digital twin of your warehouse, you can virtually test improvement ideas and scenarios.

Plant simulation allows you to compare multiple options, scenarios, and warehouse layouts, quickly choosing the best, most efficient way of working and warehouse layout based on accurate data. Changing walking or driving routes so that pickers work more effectively and complete an order faster? Or altering warehouse layouts and pathways to make it easier for forklifts to reach pallets and boxes? It's all possible in the smart warehouse!

Mendix has an app for smart warehousing that, thanks to real-time information and extensive integration capabilities with ERP and WMS systems, gives companies a much better understanding of their exact inventory and processes around logistics and warehousing. By organizing all processes paperlessly and more efficiently, companies can achieve significant cost savings, up to 25 percent, in total warehousing costs.

Building for the Future

Smart Warehousing is not a one-time implementation but rather an evolutionary process that goes hand in hand with technological advancement. A scalable, connectable, cloud-based Warehouse Management System (WMS) usually serves as the starting point. This modern WMS manages the life cycle of items in the warehouse and seamlessly integrates with various applications.

To leverage the benefits of Smart Warehousing, it is essential to first identify weaknesses in the existing system. Whether it's placing items correctly, error-free order picking, or quickly identifying warehouse items, the right technology can be applied based on specific needs and item cycle times.

With Smart Warehousing, companies can not only meet current logistics challenges but also proactively anticipate future developments in the ever-changing world of warehouse management. Below are two recent examples of two successful customer cases.

Customer Case Yala - Better Planning, Smarter Transport

For Yala Luxury Canvas Lodges, a company that develops, manufactures, sells, and assembles luxury tents on-site, we developed an application that improves planning, transport, and installation. Previously, the company largely managed these tasks manually, relying on Excel. The new smart warehousing application automates the entire process, from planning to the final assembly of boats and tents.

For Yala Luxury Canvas Lodges, a company that develops, manufactures, sells, and assembles luxury tents on-site, we developed an application that improves planning, transport, and installation. Previously, the company largely managed these tasks manually, relying on Excel. The new smart warehousing application automates the entire process, from planning to the final assembly of boats and tents.

The solution also includes extensive functionalities for team management and careful planning of the transport of all products and components. Additionally, there is a smart integration with Exact (ERP), allowing employees to effortlessly exchange data between the app and the ERP environment.

Thanks to the new application, the company benefits from:

- Less manual work

- Better and more accurate insights

- Significant time savings in creating plans

- Centralized management of various suppliers

Customer Case North Actionsports Group - A Portal for the Entire Supply Chain

For North Actionsports Group, a company specializing in manufacturing products for the action-packed world of (kite)surfing and wakeboarding, Solvos developed a special supply chain portal. The application provides:

For North Actionsports Group, a company specializing in manufacturing products for the action-packed world of (kite)surfing and wakeboarding, Solvos developed a special supply chain portal. The application provides:

- Workflow support and batch editing of data instead of manual work in Excel

- Chronological and retroactive linking of data

- The ability to make automated changes based on smart business rules

- Interfacing with the legacy ERP through smart ESB technology

The results are impressive. The company now has real-time information and insightful dashboards, while administrative tasks (such as managing stocks, orders, and shipments) proceed much faster and error-free.

Want to Benefit from a Smart Warehouse?

A modern and future-proof smart warehouse enables companies to better, more efficiently, and intelligently organize processes in their warehouse and logistics chain. Curious about how we leverage our knowledge of low-code, Mendix, digital twinning, plant simulation, and Siemens technology to set up your smart warehouse? Feel free to contact us to explore the possibilities.

Explore the Manufacturing Blog Series

This blog is part of the Manufacturing Menu blog series, which you can view here:

Last edited on Sep, 26 2024 08:41:05 AM

Reading time: 6 minutes

Written by Minke van Dooremalen | Marketing Manager

Also see..

OverviewManufacturing Menu: Enhance Your Business with Mendix Supplier Portal

Manufacturing companies operate in a complex and dynamic market landscape. One of the significant...

Read more ⟶Manufacturing Menu: Maximizing Human Capital with Modern HR Tools

Human capital is the engine that drives modern manufacturing. Of course, machines and technology...

Read more ⟶Manufacturing Menu: Enhance Your Business with Streamlined Processes

While manufacturing companies are primarily focused on production, they can only execute their core...

Read more ⟶