What is the Role of Low-Code in Manufacturing Menus—and Why Is It Transforming Digital Manufacturing?

Last edited on Jul, 01 2025 10:54:33 AM

Reading time: 6 minutes

Written by Minke van Dooremalen | Marketing Manager

Table of contents

In modern manufacturing, digital transformation is no longer a future ambition—it’s a present-day imperative. One of the most powerful yet underutilised tools driving this transformation is low-code development. Combined with the concept of a manufacturing menu, low-code is enabling manufacturers to build flexible, scalable applications that standardise processes, boost agility, and bring innovation to the shopfloor faster than ever before.

What is a Low-Code Manufacturing Menu?

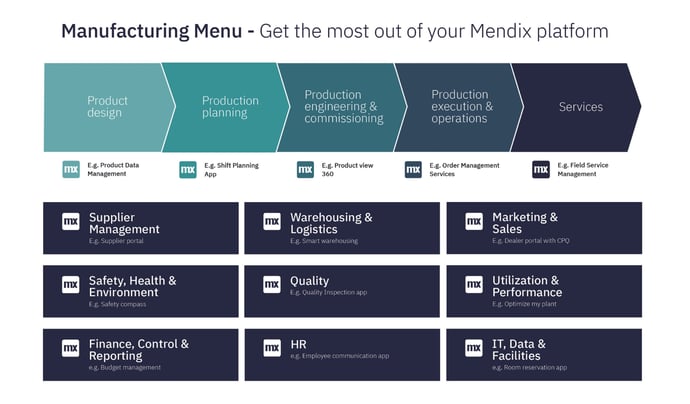

A low-code manufacturing menu is a digital, interactive framework that allows manufacturers to configure, standardise, and execute production workflows through applications built with minimal coding effort. It connects design, process planning, and execution by combining core MES functionality with low-code flexibility—often via platforms like Mendix, part of the Siemens Xcelerator portfolio.

This approach replaces manual spreadsheets and static PDFs with dynamic, data-driven apps that are accessible, updatable, and easy to use across departments.

This blog is the start of our blog series "Manufacturing Menu: Practical Manufacturing Solutions." In this article, we introduced the Manufacturing Menu and discussed why low-code is a solution for digital transformation. In the upcoming blogs, we will delve deeper into optimizing processes within specific phases of the Manufacturing Menu, sharing practical insights to elevate your manufacturing company.

Who benefits from a low-code-enabled manufacturing menu?

This innovation delivers value across multiple roles and departments:

- Production Planners: Create and modify menus based on real-time input

- Line Operators: Access accurate, digital work instructions on any device

- Quality Teams: Enforce standard operating procedures and collect data

- IT and Development Teams: Deploy apps rapidly without complex backend development

- Business Leaders: Improve visibility, traceability, and agility across manufacturing sites

Low-code allows for customisation at scale, making it easier to adapt the manufacturing menu to new products, customers, and market changes.

When should manufacturers embrace low-code for manufacturing menus?

You should consider low-code if your business is:

- Scaling up or managing product variants with complex routing

- Using Excel or manual documents to control production instructions

- Struggling with long development cycles for shopfloor applications

- Needing to enforce process standardisation across multiple factories

- Pursuing smart factory or Industry 4.0 objectives

Low-code platforms like Mendix empower companies to respond to these challenges with speed, flexibility, and minimal technical debt.

Where does a low-code manufacturing menu fit in the digital thread?

It acts as a dynamic connector between PLM, ERP, and MES systems. Here’s how:

- Teamcenter defines the product structure and BOM

- Mendix apps convert that data into a configurable manufacturing menu

- Opcenter Execution runs the process on the shopfloor

- Data flows back into analytics dashboards for continuous improvement

This integration ensures that design intent becomes executable reality—backed by traceability and real-time feedback.

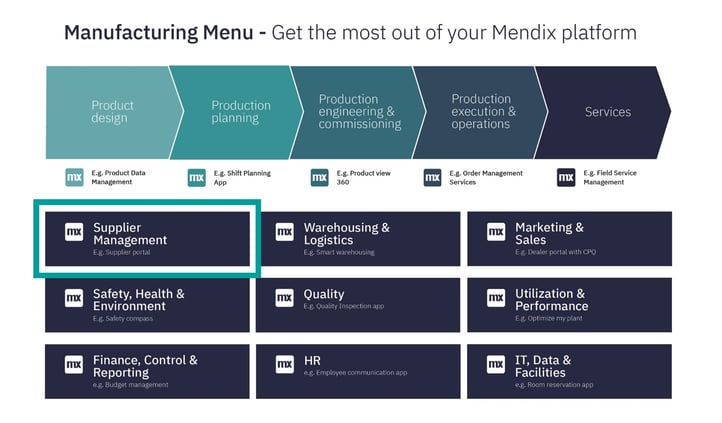

Supplier Management - Collaborate Better with Your Suppliers with a Supplier Portal

Why is low-code the future of manufacturing process innovation?

Traditional development for manufacturing applications is costly, slow, and inflexible. Low-code changes the game by offering:

- Drag-and-drop development for rapid app deployment

- Pre-built connectors to SAP, Teamcenter, Opcenter, and IoT platforms

- Role-based interfaces for specific user needs

- Faster iteration and deployment cycles

- Lower IT dependency, giving business users more control

With Emixa’s support, manufacturers can build and scale solutions that truly reflect their operations—with less time and lower risk.

What does success look like with low-code manufacturing menus?

Emixa customers using this approach have achieved:

- 60% faster time-to-deploy new work instructions

- Higher shopfloor adoption thanks to intuitive interfaces

- Fewer production errors and improved first-time-right rates

- Global process standardisation with local flexibility

- Faster response to design changes or supply chain disruptions

For example, a global manufacturer used Mendix to digitise its manufacturing menu across multiple sites—standardising instructions, enabling real-time updates, and cutting paper-based work by over 80%.

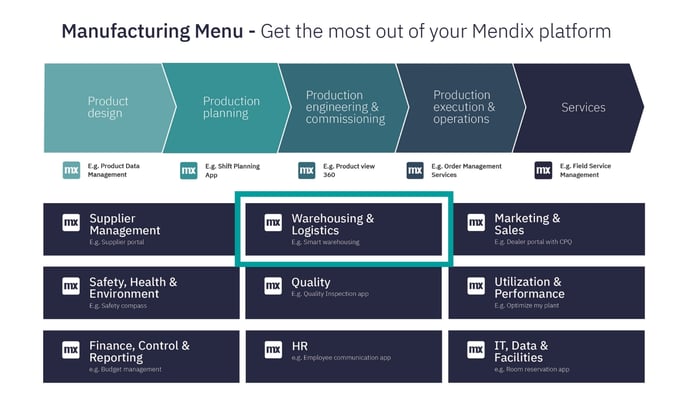

Warehousing & Logistics - Work Smarter with Smart Warehousing

Conclusion

Low-code development and manufacturing menus are a powerful combination for companies looking to streamline production, improve agility, and embrace digital manufacturing. By turning static processes into dynamic, adaptable applications, manufacturers can stay ahead in a fast-changing landscape.

With platforms like Mendix, and guidance from Emixa, you can build the flexible digital foundation needed to produce smarter, faster, and more efficiently—without reinventing the wheel.

Explore the Manufacturing Blog Series

This blog is part of the Manufacturing Menu blog series, which you can view here:

Last edited on Jul, 01 2025 10:54:33 AM

Reading time: 6 minutes

Written by Minke van Dooremalen | Marketing Manager

Also see..

OverviewWhy more manufacturing companies are adopting Smart Manufacturing

Imagine a manufacturing environment that not only does what you say, but also thinks, learns and...

Read more ⟶What is LEAN Manufacturing?

Lean manufacturing, also known as lean production, is a method of making production processes more...

Read more ⟶What is a Manufacturing Menu—and Why Is It the Secret to Building Better Products?

In today’s complex production environments, product success doesn’t just depend on design...

Read more ⟶