- Mendix

Manufacturing Menu: A Strong Foundation for the Perfect Product

Before a product reaches the market, a manufacturing company must go through various preparatory actions and processes. It starts in the design phase with a precise product design. How will the product look? What need does it fulfill? What are its functionalities and features?

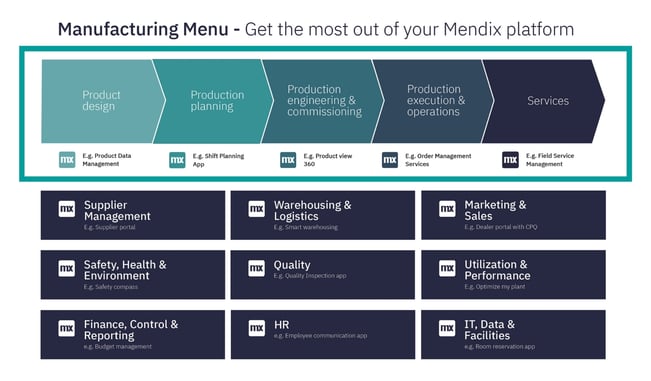

About the Manufacturing Menu

In the engineering phase, the product takes concrete shape as it is developed or improved. In the approval phase, a critical examination is conducted to ensure the design meets the specified requirements in terms of design, functionality, and expected performance. Product execution and operations refer to managing and controlling the production process to ensure products are produced on time, according to specifications, and at the lowest possible cost. Offering services is also part of the entire production process.

The phases from 'Product Design' to 'Services' come with complexity and numerous challenges. This article highlights how the Manufacturing Menu, developed in collaboration with Mendix, can contribute to organizing and streamlining these crucial parts more effectively. Concrete examples illustrate how various steps in the production process can be improved using Mendix's low-code platform.

This blog is part of the series: "Manufacturing Menu: Practical Solutions for the Manufacturing Industry" and focuses specifically on the entire production chain. In our first blog, we introduced the Manufacturing Menu, and explored how this menu provides essential solutions to support contemporary manufacturing companies in optimizing their business processes. We invite you to read this blog as well. Discover more here.

Product Design and Engineering: The Challenges

Product design and engineering lay the foundation for the final product and significantly determine whether the customer ultimately gets what they expect and need. At the same time, many manufacturing companies encounter barriers and process imperfections during these phases, often costing a considerable amount of time, money, and additional labor.

Examples of common problems during the design and engineering phase include:

-

Manual Processes and Feedback Handling:

- Large-scale manual execution of processes and manual processing of feedback, leading to time-consuming and error-prone tasks.

-

Lack of Clear and Uniform Standards for Product Data Management (PDM):

- Absence of clear and uniform standards for product data management, resulting in the lack of a universal version of the truth and increasing the risk of deviations and imperfections in the production process.

-

Difficulty in Adhering to Safety and Quality Standards:

- Challenges in complying with safety and quality standards during the design and development phase.

-

Discrepancy Between Data from Different Systems:

- Discrepancies between data from different systems (ERP, databases, CRM) due to the lack of proper links or tools for exchanging data between various data sources.

Customer Case REV'IT - Easier Collaboration, Innovation, and Design with a Smart PDM System

REV'IT, a leading manufacturer of motorcycle clothing, faced the challenge of lacking a clear and uniform standard for managing, editing, and adapting product data. The result was manual feedback on designs and the development of new, innovative designs, primarily done in Excel, consuming a lot of time due to the cumbersome and error-prone nature of the process. This was further compounded by the strict safety requirements associated with production work.

The solution was a fast, accurate, and user-friendly application built by Solvos. This application allows designers to share feedback on precisely visualized trial designs. Additionally, the app facilitates cross-functional collaboration among everyone involved in the design and production process, including designers, product engineers, and marketing personnel tasked with introducing a product to the market.

Within a period of 6 months, the versatile, smart, and future-proof PDM system was built. Thanks to the application, designers save 20 percent of the time needed to implement innovations and create new products. The cumbersome process of managing and manipulating Excel files is a thing of the past. As a result, motorcycle clothing manufacturers can bring their items to market much faster with the new application.

Customer Case NTS - Improving with BOM

NTS, a renowned manufacturer and tester of complex (opto)mechatronic systems and mechanical modules, heavily relies on bills of materials (BoM). These documents contain all the components needed for the production of a system, along with information about suppliers and costs. NTS managed BoMs for all systems in Teamcenter, while handling parts procurement in the Navision ERP system. Employees had to manually add new parts to Navision.

This manual process was time-consuming and led to discrepancies between the BOM structure in Teamcenter and the data in Navision ERP. Changes in engineering resulted in new BOMs that had to be aligned with the ERP system. Often, this was done in Excel, which is an error-prone solution. Engineers had to spend a significant amount of time (over 50 days per year) checking BOMs in Teamcenter and Navision to ensure they matched and that all the required parts were available.

To eliminate this problem and streamline workflows more efficiently, a Mendix application was built with interfaces to Teamcenter and Navision. The application compares the BOM structure in the two systems and generates various reports with accurate data on data governance and data inconsistencies. By automatically aligning all BOM and part information in Teamcenter and Navision, engineers can quickly see if incorrect parts have been ordered, the lead time for a part, and whether the BOM data in Teamcenter and Navision ERP match. By eliminating manual tasks, reducing errors, and saving time (from over 50 days to one day per year), engineers can process and check large bills of materials more efficiently.

Want to Know More About Our Solutions?

Modern technology offers numerous solutions to the most significant challenges in product design and engineering. Low-code, especially, enables the rapid deployment of specialized and fully functional applications for complex and specific challenges within the manufacturing industry using platforms like Mendix. Curious about how we leverage our knowledge of low-code, Mendix, digital twinning, plant simulation, and Siemens technology can help you with this? Feel free to contact us to explore the possibilities.

Explore the Manufacturing Blog Series

This blog is part of the Manufacturing Menu blog series, which you can view here:

- The Manufacturing Menu

- From Product Design to Services

- Supplier Management

- Warehousing & Logistics

- Marketing & Sales

- Safety, Health & Environment

- Quality

- Utilization & Performance

- Finance, Control & Reporting

- HR

- IT, Data & Facilities

Author: Minke van Dooremalen | Marketing Manager

Published date: August 26, 2025

Explore our Technology. Access our downloads center.

Access NowStart your Digital Transformation with Emixa

We help businesses transform their digital future with cutting-edge technology and strategic products & services