Manufacturing Menu: Ensuring Safety & Health with the Right Technology

Last edited on Aug, 14 2024 08:35:02 AM

Reading time: 6 minutes

Written by Chelsea Delich

Table of contents

We live in an era where corporate social responsibility (CSR) holds a prominent place on the priority lists of companies and regulatory bodies within the manufacturing industry. As requirements become increasingly stringent and expectations higher, safety, health, and environmental consciousness collectively form a key ingredient of Emixa's Manufacturing Menu.

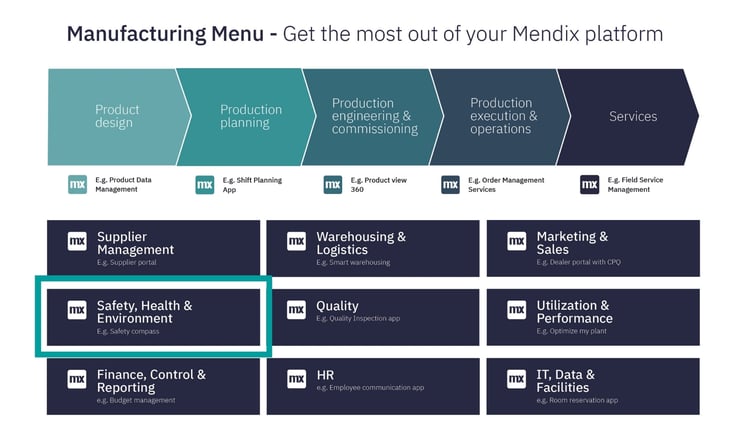

About the Manufacturing Menu

The Manufacturing Menu addresses all stages and areas of production within manufacturing companies, focusing on specific challenges. It offers practical solutions to promote agility, innovation, and adaptability through Mendix's low-code platform. In this article, you will discover how employing a robust safety compass alongside modern and intelligent technology can establish a solid foundation for safety and sustainability.

This blog is part of the series: "Manufacturing Menu: Practical Solutions for the Manufacturing Industry" If you are also interested in the benefits of a modern dealer portal and how they can be modularly expanded to suit your needs, we invite you to read this blog as well. Discover more here.

The Burden of Manual Processes

Despite the great importance of safety, many manufacturing companies still encounter several challenges in monitoring these pillars of healthy operations. One prevalent issue is the absence of standardized procedures coupled with extensive manual labor.

Maintaining consistent records and documentation of work, safety, and environmental standards remains a significant hurdle. Often, systems for recording such standards or reporting safety concerns on the shop floor are cumbersome and not user-friendly. Employees are burdened with the task of manually entering extensive and complex forms, leading to inefficiencies.

This cumbersome process can lead to several problems. Employees may resort to their own improvised methods, deviating from established work standards. Alternatively, they may choose to forego safety reports altogether, deeming the time and effort required for documentation outweigh the perceived risks. Consequently, there is an increased likelihood of safety incidents and non-compliance with environmental regulations.

Another challenge is evacuating the shop floor in the event of an emergency. Especially when working with paper systems or Excels, it is often difficult for managers to oversee whether everyone is present (think of sick people or people who have time off but are on the list) and all employees are present on time at the desired assembly point.

Safety in the Corporate DNA With a Strong Compass

With a good safety compass and the right technical tools, you can ensure that safety and quality assurance become an inseparable part of all your business processes and nestle firmly into the organizational culture. A safety compass consists of the set of procedures, guidelines, rules, tools, documentation and awareness that ensures a safe working environment. Specialized applications make it easier to consistently comply with the safety compass and carefully check all sub-processes within the overall production process for safety.

Customer Case VDL Nedcar - Always Reliable Security Rounds Thanks to Security Round App

For VDL Nedcar, one of Europe's most progressive and best car manufacturers, Emixa built the security round app. The purpose of this solution? To ensure that security rounds in the buildings and factory halls actually walked and to exchange paper checklists for an automated solution that is faster and less prone to errors.

For VDL Nedcar, one of Europe's most progressive and best car manufacturers, Emixa built the security round app. The purpose of this solution? To ensure that security rounds in the buildings and factory halls actually walked and to exchange paper checklists for an automated solution that is faster and less prone to errors.

With the security round app, people can log in, choose a route and scan NFC tags (it is one of the first Mendix applications to use this) they encounter during their round. The application records the time and the name of the security guard, so you can always be sure that a round has actually been walked. In case of any emergencies, it is possible to quickly send an e-mail and take photos of the situation. The application records all data, is very transparent and makes security checks much more efficient.

Customer Case VDL Nedcar - Quick and Safe Evacuation

For the same car manufacturer, VDL Nedcar, Emixa also developed and built the evacuation app. Previously, in the event of an evacuation, managers still used a paper list and manually ticked off all the names. With that method of working, managers lacked direct insight into any missing employees (think people who are sick or have time off).

For the same car manufacturer, VDL Nedcar, Emixa also developed and built the evacuation app. Previously, in the event of an evacuation, managers still used a paper list and manually ticked off all the names. With that method of working, managers lacked direct insight into any missing employees (think people who are sick or have time off).

Thanks to the new progressive webapp (application software delivered via the internet), security receives a notification when an evacuation takes place in a particular department. All managers then receive a call on their phones to open the app. A connection to the MDEC app ensures that managers get an up-to-date overview of who is working and can immediately call the emergency services. The result? An accurate, reliable and paperless process that ensures optimal safety for everyone in the event of an emergency and evacuation.

Want to Improve Safety in your work environment?

Do you want to take your safety and security to the next level? Curious about how we leverage our knowledge of low-code, Mendix, digital twinning, plant simulation, and Siemens technology can help you with this? Feel free to contact us to explore the possibilities.

Explore the Manufacturing Blog Series

This blog is part of the Manufacturing Menu blog series, which you can view here:

Last edited on Aug, 14 2024 08:35:02 AM

Reading time: 6 minutes

Written by Chelsea Delich

Also see..

OverviewManufacturing Menu: Maximizing Human Capital with Modern HR Tools

Human capital is the engine that drives modern manufacturing. Of course, machines and technology...

Read more ⟶Manufacturing Menu: Smart Solutions for Future Warehouse Management

In the dynamic world of logistics and warehouse management, companies face the challenge of...

Read more ⟶Manufacturing Menu: The Power of Quality Management and Compliance

In the fast-paced world of manufacturing, ensuring world-class quality isn't just a nice to have -...

Read more ⟶