HBM Machines

Your expert partner in future-proofing yourbusiness to optimize and improve

Business Challenges

• Growing IT systems with explosive business growth

• Inadequate interfaces and communication between systems

• Parallel implementation of new systems and processes

Keys to Success

• Implementation of a new ERP system

• Implementation of Boomi integration: connecting applications

• The IT team trained to become Boomi experts

Results

• Improved operational excellence and error reduction

• More efficient data analysis and problem-solving

• Seamless processes for large data and order volumes

Case | HBM Machines Waddinxveen | Operational Excellence

HBM Machines is a supplier of machines, hand tools and technical accessories. The company focuses on a wide range of professional fields and applications. Think of metalworking, woodworking, sheet metalworking, garage equipment and automotive articles, for example. Many items are also under their own brand. "Truly everything for your workplace" is therefore HBM's slogan.

Business Challenges

Keys to Success

Results

"You can really tell that 'operational excellence' has improved," Detlef notes. "Errors happen less often, and if something goes wrong, it's easy to find and fix. Setting up the software correctly saves a lot of time and money. In the end, the goal is to have processes that work smoothly, handling large amounts of data and orders without any problems."

Efficient System Integration at HBM Machines

What I really like about Emixa is that there is a real methodology behind the software. For example, you use an RM methodology for training and certifying employees. In addition, Emixa works with clear protocols and logical process steps. It really helps if you have an implementation partner that lets you work according to a fixed framework of building, testing and documenting. Our rapidly growing organisation needs that.

Detlef de Vries

CFO of HBM Machines

Explore our Portfolio

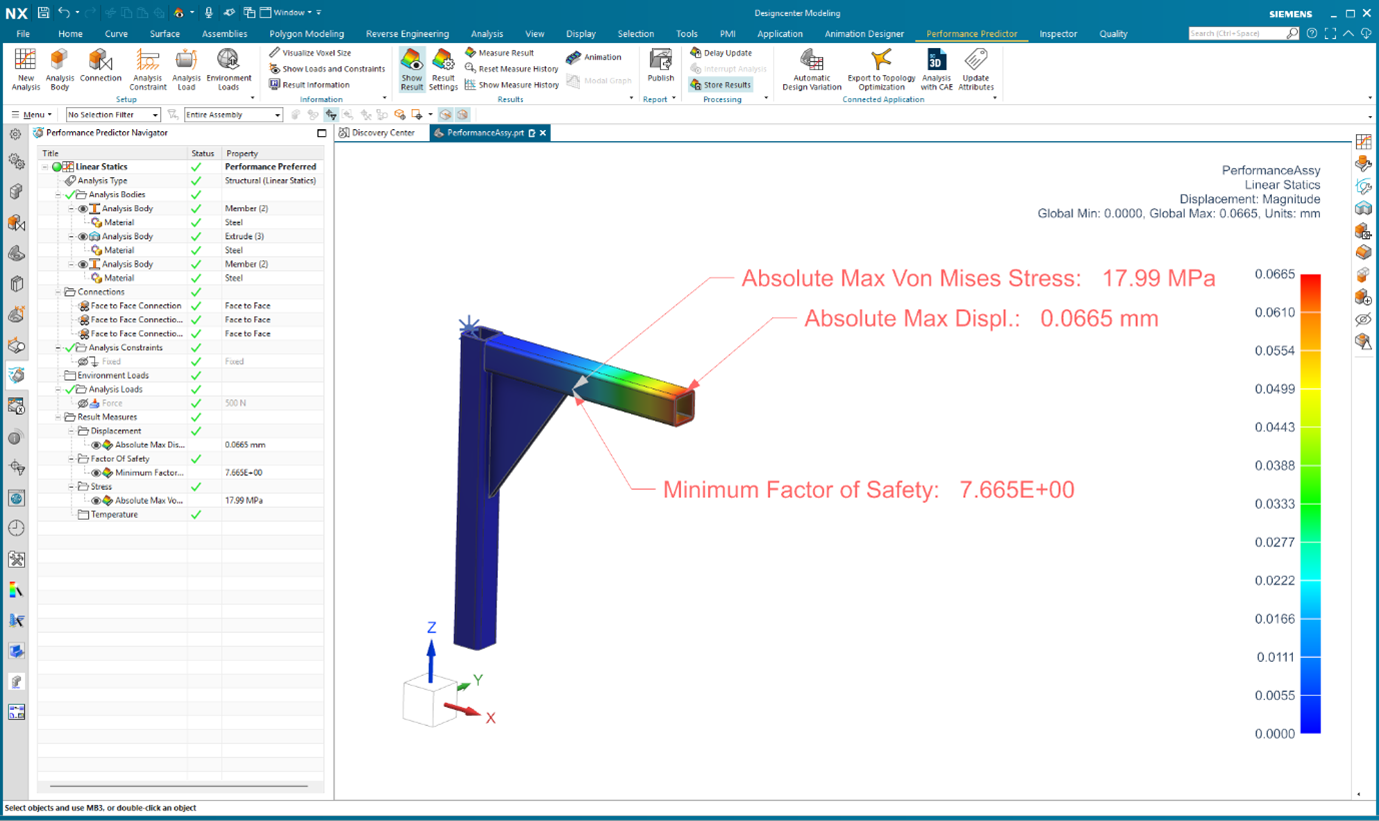

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.

Data & Analytics

Expertise in Data Analytics tailors BI & AI strategy, data science, engineering, IoT platforms, ESG reporting, and financial analytics in the manufacturing industry.

Management Consulting

Management Consulting offers strategic guidance in the manufacturing industry, fostering digital transformation and operational improvement.

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.