Mevi's Siemens NX™ CAD-CAM Journey

Your expert partner in future-proofing yourbusiness to optimize and improve

Business Challenges

• Daily challenges in new product development

• Rapid, effective programming for machinery

• Demand for efficient computer-based programming

Keys to Success

• Balancing craftsmanship with automation strategy

• Leveraging software amid labour constraints

• Siemens NX™ CAD-CAM for production efficiency

Results

• Siemens NX™ enables complex production

• Cross-departmental use enhances efficiency

• Increased production efficiency and resource use

Case study Mevi Group

Mevi, with a legacy spanning over 50 years, specialises in designing, developing, and manufacturing parts, modules, and machines. This family-owned business expertly manages the entire supply chain, overseeing projects from the initial concept through to final implementation. Operating with a team of 125 employees, Mevi has established its presence across four locations: two in the Netherlands, one in Belgium, and one in the Czech Republic. Renowned for handling projects involving low volumes and high complexity, Mevi caters to diverse industries such as high-end machine building, printing, aerospace, medical, and semiconductor sectors.

Business Challenges

At Mevi, each day is defined by the challenge of developing new products, unlike organisations focused on optimising a single product. Their primary challenge is to program these new products swiftly and effectively, ensuring the efficient use of their machinery. Furthermore, the complexity of the products they are tasked to create often exceeds the scope of manual machine programming. This demands the adoption of smart computer-based programming methods to maximise the valuable time of Mevi's skilled employees.

Keys to success

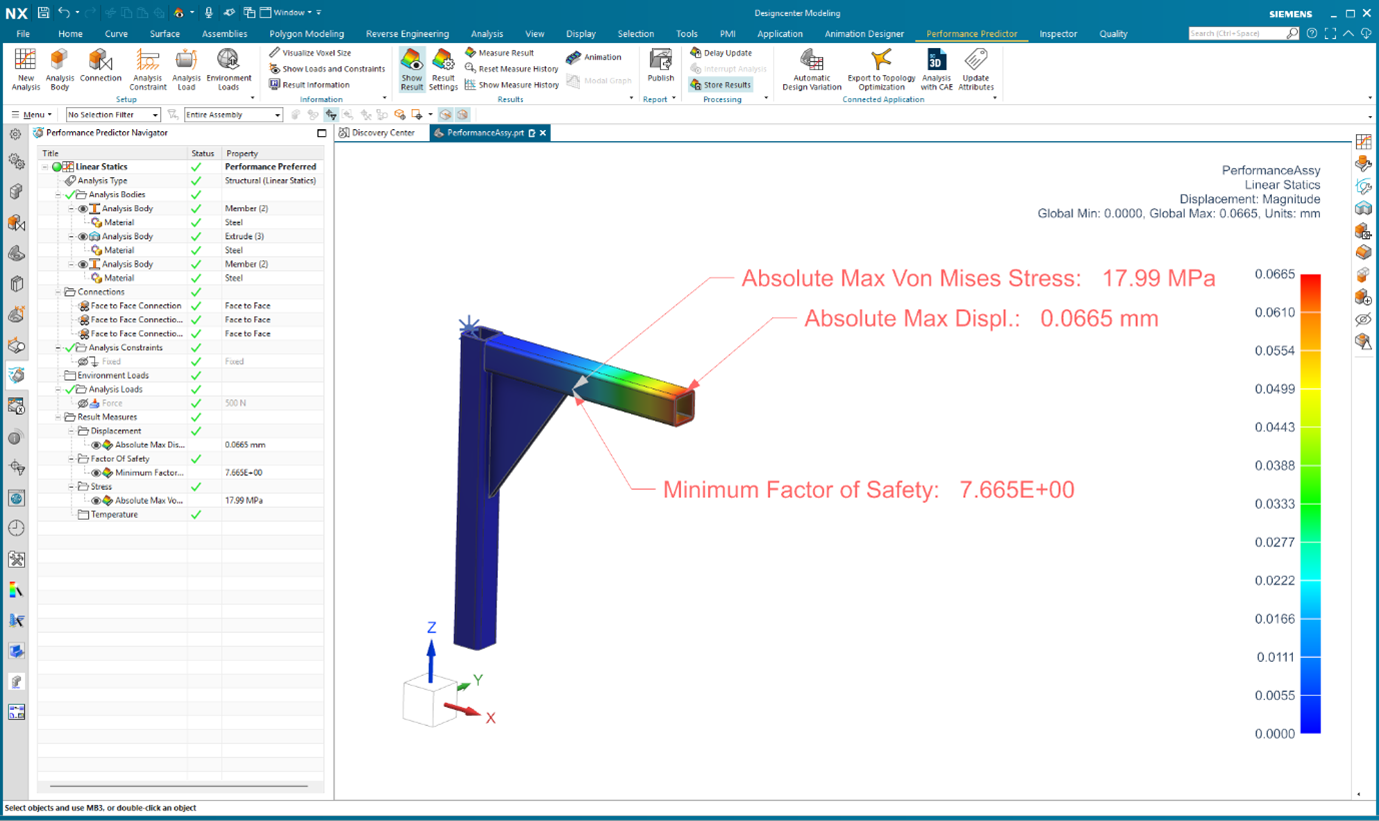

Mevi aimed to find the perfect balance between craftsmanship and automation, especially in a tightening labour market. Their goal was to use software for routine tasks, freeing their skilled workforce to focus on areas where software falls short. This approach was key to managing increasing task complexities and meeting evolving customer demands. Communication was crucial – how to seamlessly share data and minimise transitions between software applications, ensuring that software never becomes a bottleneck. To address these challenges, we implemented Siemens NX™ CAD-CAM, a design, programming, and simulation solution. This allowed the engineering team and CAM programmers to meet and exceed customer expectations despite growing complexities in parts and assemblies. The result was a significant boost in the efficiency and effectiveness of the production process. However, the impact of this solution extends beyond the production floor. It's used across almost the entire organisation. For example, the sales and quoting team employs CAD-CAM for quick simulations, greatly enhancing the pre-production stages.

Results

The adoption of Siemens NX™ CAD-CAM has led to remarkable outcomes for Mevi. This software has expanded their manufacturing capabilities, enabling them to produce complex products that were once unattainable. It empowers the engineering team and CAM programmers to meet and often surpass customer expectations, especially with increasingly complex parts and assemblies. The comprehensive application of the software has greatly improved efficiency across various production processes. Consequently, Mevi has achieved more effective utilisation of both human and machine resources, marking a significant stride in their operational capabilities.

Explore our Portfolio

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.

Data & Analytics

Expertise in Data Analytics tailors BI & AI strategy, data science, engineering, IoT platforms, ESG reporting, and financial analytics in the manufacturing industry.

Management Consulting

Management Consulting offers strategic guidance in the manufacturing industry, fostering digital transformation and operational improvement.

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.