Mastering Mobility: How MasterMover Transformed Heavy Load Handling

Your expert partner in future-proofing your business to optimize and improve

Business Challenges

• Tripled annual turnover over eight years

• Significantly reduced development time

• Enhanced collaboration between design team, shop floor and the field

Keys to Success

• Traceability of all components

• Ability to standardize parts and processes

• Virtual testing and assembly

Results

• Re-use of design data cuts development time

• Precise geometry ensures designs are right first time

• Rapid decision making – down from days to minutes

Mastering Mobility: How MasterMover Transformed Heavy Load Handling

Formed in 1997, MasterMover set out to provide a retail industry solution for moving multiple cages around supermarkets. It developed a unit that removed the effort and danger associated with moving wheeled loads by using a leveraged weight transfer system and a powerful electric motor. This unit could be adapted to any customer’s needs, and MasterMover soon found that it was responding to demand from many industries.

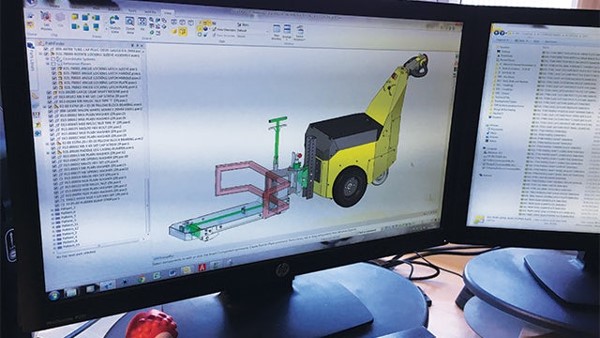

Since then, it has grown a completely new market with an extensive range of adaptable designs. These are all created using Solid Edge® software from product lifecycle management (PLM) specialist Siemens Digital Industries Software. The 3D design solution enables the company to re-use design data, streamline communication within the company and support sales and customer service.

Business Challenges

One key aim for MasterMover was to bring more structure to the business by creating full traceability. In particular, the company wanted to leverage elements of the many customized solutions it had delivered over the years. “What we originally had was a drawing system that was independent of everything else,” explains Owen. “It made it very difficult for any individual to know exactly what we had done in the past, which meant that we often duplicated designs.”

The design department used Solid Edge to create a logical numbering method for all components and subcomponents. In combination with a searchable and filterable database, the design, sales, stock and service functions all employ exactly the same identification codes.

According to Owen, traceability is key to quality and service; for example, a customer may want a unique coupling and then request a revision further down the line. In addition, traceability saves huge amounts of time. “The speed with which we can now develop comes from our ability to change and re-use data, and Solid Edge was the catalyst for this,” comments Owen. “Everything comes from the drawings. If we need to trace a part number from a sales invoice or Bill of Materials, we can do so in an instant. Before, this process could take days.”

Keys to Success

Sam Dance, design manager at MasterMover, describes why he likes using Solid Edge. “It is intuitive and easy to use, so a new user can be productive within days. The interface can quickly be customized to an individual’s way of working and it has seemingly small features that make a huge difference to our productivity. For example, our machines have assemblies within assemblies, and on drawings we regularly need to highlight certain areas. It is massively useful to be able to do this. With Solid Edge we can communicate clearly with colleagues on the shop floor and with field engineers because they can all view our digital models directly.”

MasterMover uses engineering design to drive sales. “If a customer comes to us with a request we look at standard parts first, then we may move on to conceptual ideas and create a new design,” Dance explains. “With the visualization capabilities of Solid Edge we can clearly show detailing without the need to prototype.” Owen adds: “Solid Edge has helped sales and development because customers understand the direction we are going in. It brings about quality and efficiency of working. I can’t see how we could work without it.”

Results

Between 2007 and 2015, MasterMover experienced tremendous expansion. Exports, which accounted for less than five percent of turnover before 2007 increased by a multiple of nine and now represent more than 45 percent of turnover.

“Our business develops hand in hand with Solid Edge because there are such good connections between the design team and the sales team,” Owen says. “Design helps sales to bridge understanding with customers, which means that we have significantly reduced development time. This contributes to our growth.”

Whereas the MasterMover range formerly consisted of three basic models, the company now has 25 different models, including stainless steel machines that meet demanding hygiene standards. Five new products were launched in 2015 alone.

“We have a highly adaptable product that is establishing standards of quality and safety in a new sector and we could not manage this without Solid Edge.”

Explore our Portfolio

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.

Data & Analytics

Expertise in Data Analytics tailors BI & AI strategy, data science, engineering, IoT platforms, ESG reporting, and financial analytics in the manufacturing industry.

Management Consulting

Management Consulting offers strategic guidance in the manufacturing industry, fostering digital transformation and operational improvement.

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.