Your expert partner in future-proofing yourbusiness to optimize and improve

Business Challenges Experts

• Upgrading 15-yr-old layouts to 3D

• Lantech seeks process-aligned machine build

• Integrating processes with modular solutions

Keys to Success

• Standards-based customisation with Lantech

• Building block' reuse for customer solutions

• Siemens NX™ and Teamcenter® for digitised data

Results

• Tripled machines for production, no extra staff

• Reduced error margins achieved

Lantech | Case Handling Machinery | Manufacturing Efficiency

Lantech, renowned for its packaging machinery, has been safeguarding products and shipments for about 47 years. Starting from humble beginnings in a garage, the company has grown into a major global entity in box and pallet handling machinery, thanks to strategic mergers and consistent growth over nearly five decades. Presently, Lantech has a widespread presence with offices across four continents, two manufacturing sites, and extensive global sales and technical support networks. Their box erectors and wrappers have a worldwide reach. The company serves a diverse range of markets, including retail, E-commerce, pharmaceuticals, and the food industry.

Business Challenges

Approximately 15 years ago, a significant shift occurred in layout designs, moving from traditional paper drawings to comprehensive 3D presentations. This transition marked an increase in complexity. In response, Lantech was in search of a partner capable of constructing specialised machines based on predefined standards, ensuring alignment with their associated processes. During this period, although many solutions offered modularisation, they often faced challenges in effectively integrating with the essential underlying processes. This highlighted the need for more sophisticated, process-integrated solutions in machine design and development.

Keys to Success

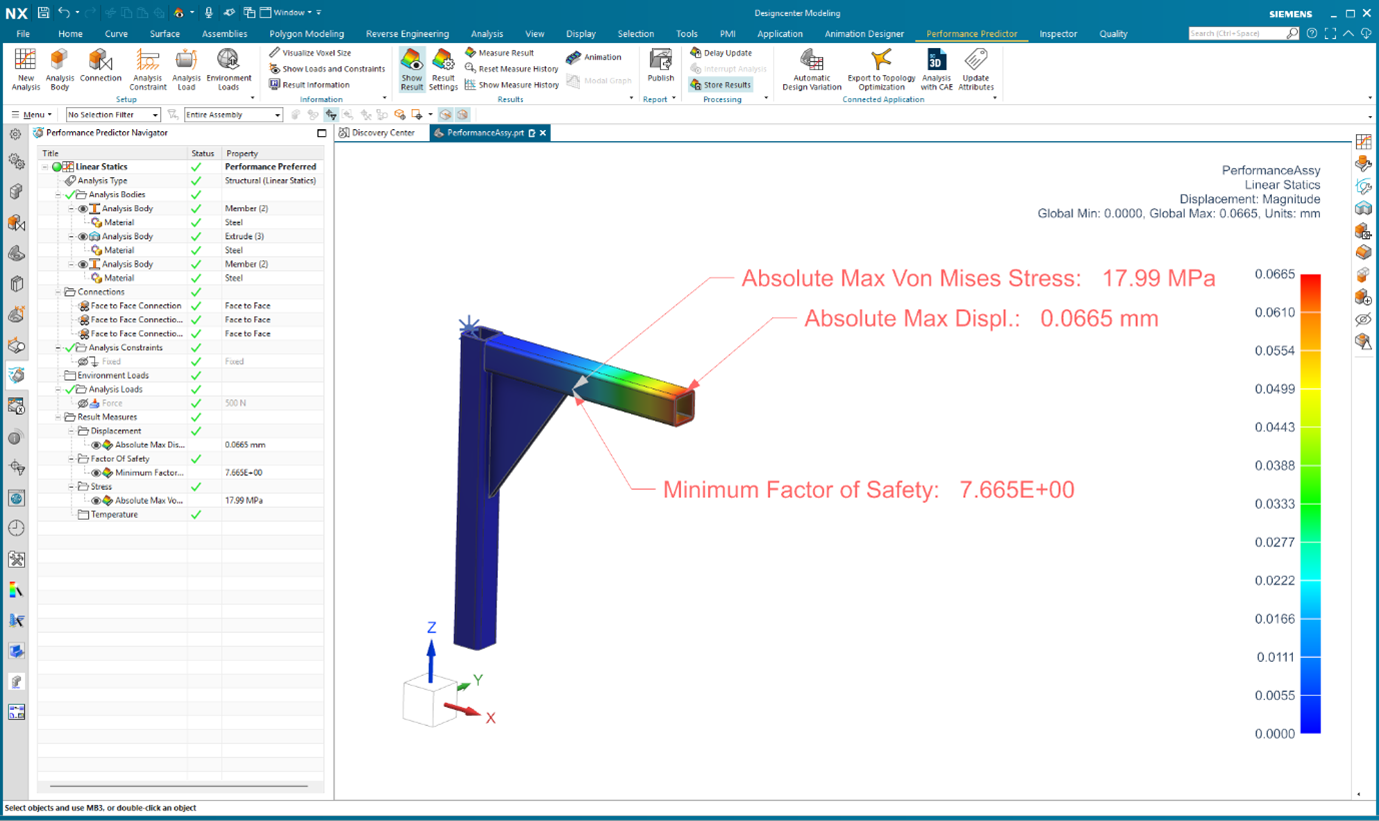

To address the market's need for rapid, efficient solutions tailored to customer needs, Lantech focused on delivering customisations derived from established standards. Their approach involved intelligently reusing 'building blocks' managed by software, enabling the configuration of customer-specific solutions without the need for ground-up engineering. This strategy included extensive support for full customisation. To facilitate this, we integrated Siemens NX™ and Teamcenter® into Lantech's operations. This integration enabled Lantech to digitally share all design data, both internally and with customers, allowing for the creation of client-specific solutions from a standardised master model. Additionally, it streamlined production management with suppliers, enhancing control over procurement, assembly, maintenance, and service.

Results

Tripled machine releases for production, no extra staff needed, with reduced error margins.

Explore our Portfolio

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.

Data & Analytics

Expertise in Data Analytics tailors BI & AI strategy, data science, engineering, IoT platforms, ESG reporting, and financial analytics in the manufacturing industry.

Management Consulting

Management Consulting offers strategic guidance in the manufacturing industry, fostering digital transformation and operational improvement.

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.