Business Challenges

- Navigating cost-effective and scalable machine investments.

- Managing planning complexity across manual workflows and operational silos.

- Lack of data-driven insight into future scenarios and bottlenecks.

Keys to Success

- Building a high-fidelity Digital Twin Simulation aligned with real-world operations.

- Collaborating closely with Kornelis’ internal systems expert for accurate data modelling.

- Using simulation to inform layout changes, reduce operator strain, and justify investments.

Results

- Reduced projected lead times by up to 85% through high-speed machine modelling.

- Confirmed the ROI potential of €250K+ investments ahead of execution.

- Strengthened planning agility and laid a foundation for future automation.

From 3 Weeks to 3 Days: How Kornelis Improves Lead-Time by 85%

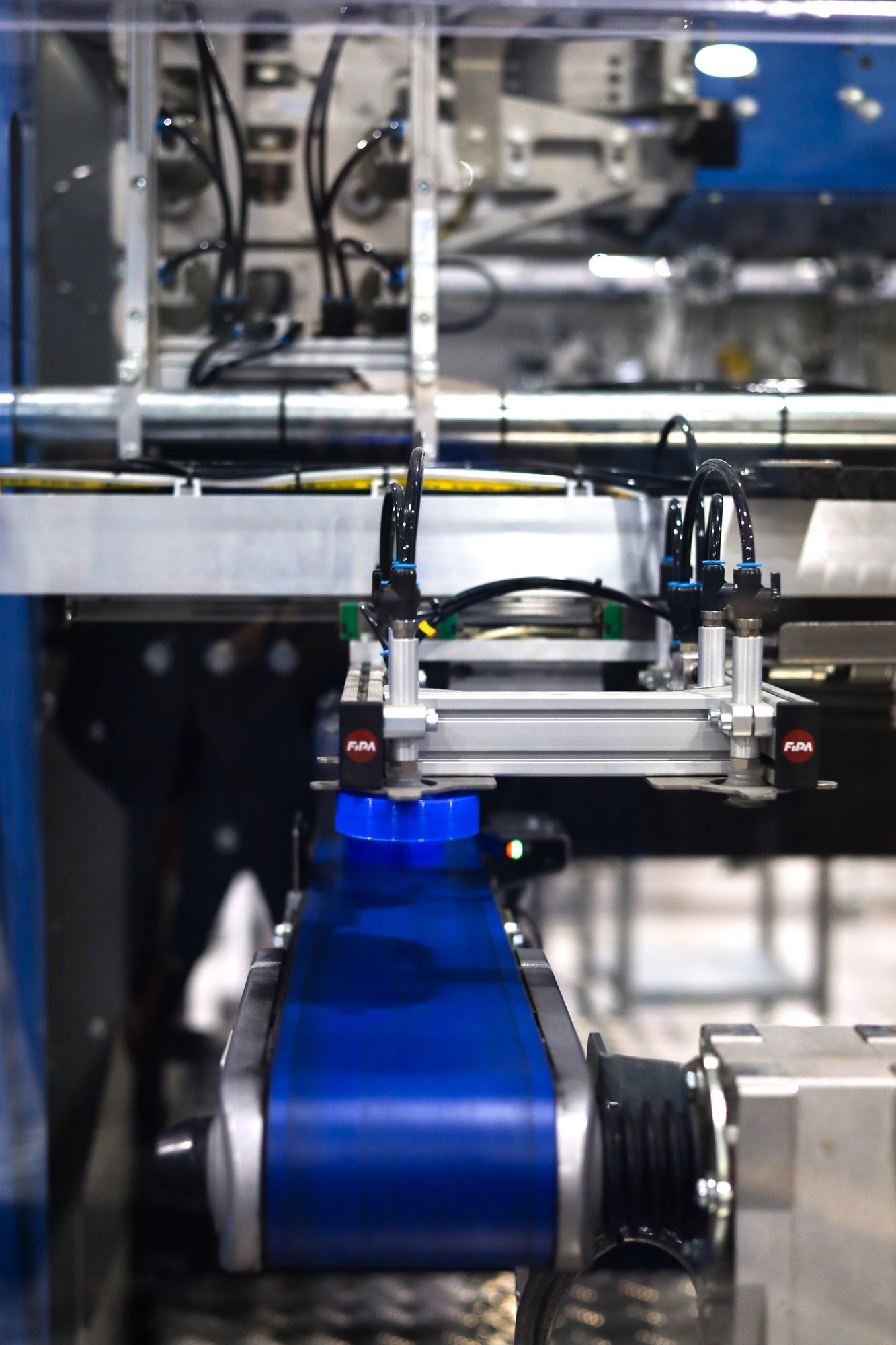

Kornelis, a specialist in producing caps and closures, was preparing for its next phase of growth. Their goal was to make smarter, faster investment decisions to stay competitive, without relying on knowledge siloed within just a few key individuals.

By partnering with Emixa to build a Digital Twin Simulation, Kornelis was able to test assumptions in a virtual environment before committing capital in the real world. The result? Faster lead times, more precise planning, and a scalable model for continuous improvement.

Mapping the Way Forward

Kornelis is no stranger to digital operations. Its MES system is fully integrated with the shop floor via tablets. But as production demand grew and product diversity expanded, new strategic questions emerged:

- Which machines should we invest in next?

- Where are our real bottlenecks?

- How do we validate future planning decisions?

The complexity of their operations, combined with an ambition to serve new markets, meant that traditional planning tools were no longer enough. They needed more than just spreadsheets; they needed simulation-driven foresight—something dynamic, predictive, and grounded in operational data.

From Insights to Action

Working closely with Kornelis’ functional system administrator, our team at Emixa developed a high-fidelity Digital Twin using Siemens Tecnomatix’s Plant Simulation software. This wasn’t a test run—it was a decision-making engine.

Together, we simulated key scenarios:

- Adding high-speed injection moulding lines

- Converting older machines to inline processing

- Assessing the impact of logistics tasks on operator workloads

- Evaluating layout efficiencies and machine allocation strategies

The results were eye-opening. One scenario revealed that a job typically taking 3 weeks on a legacy line could be completed in just 3 days with a high-speed setup—an 85% improvement in lead time.

The model also validated a long-standing concern: operators were spending a disproportionate amount of time on manual logistics, confirming the case for AGV-based automation.

Unlocking Tomorrow’s Potential

This wasn’t a one-off project—it laid the foundation for Kornelis’ long-term digital strategy. Today, the Digital Twin is used to explore product-mix organisation, validate layout redesigns, and support high-stakes investment decisions.

Looking ahead, Kornelis sees potential in connecting AI to their injection moulding equipment and exploring areas of AGV-based automation where simulation could offer additional value down the line. The model has already shaped how they approach production planning, and the next phase will focus on even more targeted, high-value scenarios.

Thanks to a collaborative approach and strong internal engagement, future expansion will be faster, leaner, and more impactful.

Most manufacturers know they need to modernise, but few have a clear roadmap. Kornelis’s story demonstrates that:

- A well-built Digital Twin saves time, money, and stress

- Simulation enables confident, data-driven decision-making

- Strategic collaboration turns complexity into clarity

Shaping the Future of Manufacturing—One Outcome at a Time

“Emixa is ahead of the curve when it comes to digital manufacturing. They helped us turn complex decisions into clear outcomes. The collaboration was smooth, structured, and effective—and the results speak for themselves.”

Jeroen Frederiks

Functional System Administrator

Curious how a Digital Twin could reshape your next big decision? Let Emixa show you how.

Connect with A Simulation Expert today.