Lighting the Way: How Designplan is Innovating Illumination Solutions

Your expert partner in future-proofing your business to optimize and improve

Business Challenges

• Respond to customer requests easily and quickly

• Amend standard products with speed

• Utilize historical data effectively

Keys to Success

• Consolidate CAD on one platform

• Enable easy learning and sharing

• Create master models of all standard products

Results

• Increased rate of customized designs from five to eight per week

• Reduced 10 to 18 production stoppages per week to four

• Accelerated design of customized options

Lighting the Way: How Designplan is Innovating Illumination Solutions

For half a century, Designplan Lighting has been making weather- and vandal-resistant luminaires that have tough bodies, tightly sealed diffusers and tamperproof screws. The company’s extra-strong light fittings can be found in airports, train stations, housing estates and secure health care units. Specialist products are available for specific situations, such as custodial settings where care must be taken to prevent harm through the design of smooth rounded surfaces to which a ligature cannot be attached. In underground railway systems, lighting units must incorporate additional anti-fire and anti-smoke features.

With more than 140 employees and sales in over 20 countries worldwide, Designplan is a leader in using the latest techniques and materials. A pioneer in light-emitting diode (LED) lighting, the company’s comprehensive portfolio includes an extensive range of energy-efficient fittings that are environmentally friendly and low maintenance. Part of the Fagerhult Group, it has a modern factory in south London. Designplan makes both standard and customized lighting products, and it was the particular challenge of making customized products that led Designplan to review its use of technology in the development process.

Business Challenges

Tony Croke, design team manager, explains: “Over the years, the company had acquired multiple CAD platforms, so when we had to quote for a new product we faced a whole series of questions: which existing model was closest to what was required, which package had it been designed in and who was most familiar with that software? Our vision was to consolidate on one package and improve our efficiency.”

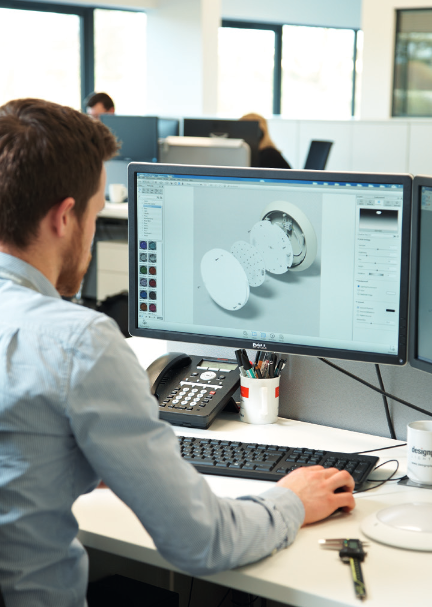

A demonstration from Siemens Digital Industries Software solution partner Emixa Industry Solutions convinced the Designplan team that Solid Edge® software with synchronous technology was the way forward. “It was clear that if we created a master model for each product we could use synchronous technology to modify attributes such as height and length easily and quickly,” Croke says. Solid Edge was implemented early in 2016 and rolled out to nine design engineers who received tailored in-depth training from PCE and

from Siemens.

Keys to Success

“I find Solid Edge very intuitive to learn and it gives us better tools,” says Amy Deeprose, design engineer at Designplan. “Solid Edge also has a lot of features that are extremely helpful, for example the ability to pattern a feature. Playback is particularly useful. If I go away from a project and return to it later, it’s really easy to see the steps I took before and continue without losing any time. I can also share this feature with colleagues to demonstrate how to do something. There is much assistance available from the wider Solid Edge community and I often obtain information from online resources.”

After six months, Designplan had created master models for three product sets and the team was reviewing customer requests and anticipating demand for different sizes. Deeprose notes the benefits of the new approach: “In particular, synchronous technology allows us to work organically. We can explore options because there is no sketch to build as in an ordered modeling environment. When we have a Solid Edge assembly we can do model explosions and gain visual help to cross-reference quickly against the master BOM (bill of materials).”

John Hough, bespoke design engineer, focuses on customized products. “I had worked for 25 years with CAD, but moving to Solid Edge opened my eyes to what is possible. I love synchronous. I find it very quick to manipulate an existing model in order to change a fitting, lengthen a luminaire, reposition a hole or amend a pitch. I am saving more than half the time I previously spent making changes at the part and assembly level.”

Results

The first products designed using Solid Edge went into production nine months after implementation. “We can make an assembly much more intelligent; it is so easy to set up components and alter them as required,” Deeprose explains. “Now that we have started to work from master models, any changes are taking minutes rather than hours.”

“We are finding that Solid Edge allows us to upgrade the technology within a product quickly and easily and this extends operating life,” Hough adds. “Local authorities are saving costs by replacing sodium lighting, and retrofitting LED elements into an existing fitting takes just a few minutes.”

According to Croke, there has been a huge opportunity to freshen up the company’s top revenue-producing products. “We will have addressed 90 percent of our best sellers within one year,” he notes. “In addition, we have improved our products and reduced manufacturing errors. Production stoppages for bespoke products used to average between 10 and 18 per week. Since we began to use Solid Edge, they have dropped to just four.”

Explore our Portfolio

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.

Data & Analytics

Expertise in Data Analytics tailors BI & AI strategy, data science, engineering, IoT platforms, ESG reporting, and financial analytics in the manufacturing industry.

Management Consulting

Management Consulting offers strategic guidance in the manufacturing industry, fostering digital transformation and operational improvement.

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.