Your expert partner in future-proofing yourbusiness to optimize and improve

Business Challenges

• Develop a dedicated outboard engine and matching business model to succeed in the global marine industry as a small British startup

• Design and engineer a marine diesel outboard engine that is more fuel-efficient yet highpowered, more durable, and cleaner

• Integrate the right digitalisation tools to succeed in product development and to support a growing international business model

Keys to Success

• Implemented an end-to-end digitalized design and development process

• Developed a highly accurate digital twin of the CXO300 engine

• Solid commitment from a small, passionate and experienced team of engineers

Results

• Achieved 25 percent more fuel efficient and cleaner outboard engine

• Developed an engine that is expected to last three times longer than comparable models

• Saved hundreds of thousands of pounds in costs and months of development time

Case study Cox Marine

British startup Cox Marine ready to revolutionize the outboard engine industry thanks to digitalisation. Cox Marine is a British company that specializes in designing and producing diesel outboard engines for marine applications. The company was founded in 2007 and is based on the South Coast of England. Cox Marine is known for its innovative CXO300 engine, which is the world’s first 300hp diesel outboard engine.

Business Challenges

The bigger commercial picture aside, creating a bespoke, horizontal V8 engine for the marine market requires a high level of excellence when it comes to engineering. Excellence is in the heart and soul of Cox Marine.

It all started in 2007 when motorsports racing engineer David Cox came up with the idea to develop a lightweight diesel outboard using Formula One® (F1) technology. Charles Good joined as chairman and this idea was extended to the diesel outboard market the next year. When the first concept engine was fired up in 2010, Cox Marine was still a very small team of four or five people.

Over the next years, the team worked on the alpha and beta engine versions in partnership with Ricardo. In 2014 the current CEO, Tim Routsis, a former Cosworth executive and a serious racing insider, joined the company and started to push Cox Marine into the market as a global player. Over the next five years, engineers and experts from all types of fields from marine and automotive to motorsports and aviation joined the team.

Everyone shared a single credo: a passion for fast engines and the belief that Cox Marine could change the marine industry for the better. Translating this passion and vision into a high-performance reality posed many technical challenges, and getting it right was mission-critical.

Keys to Success

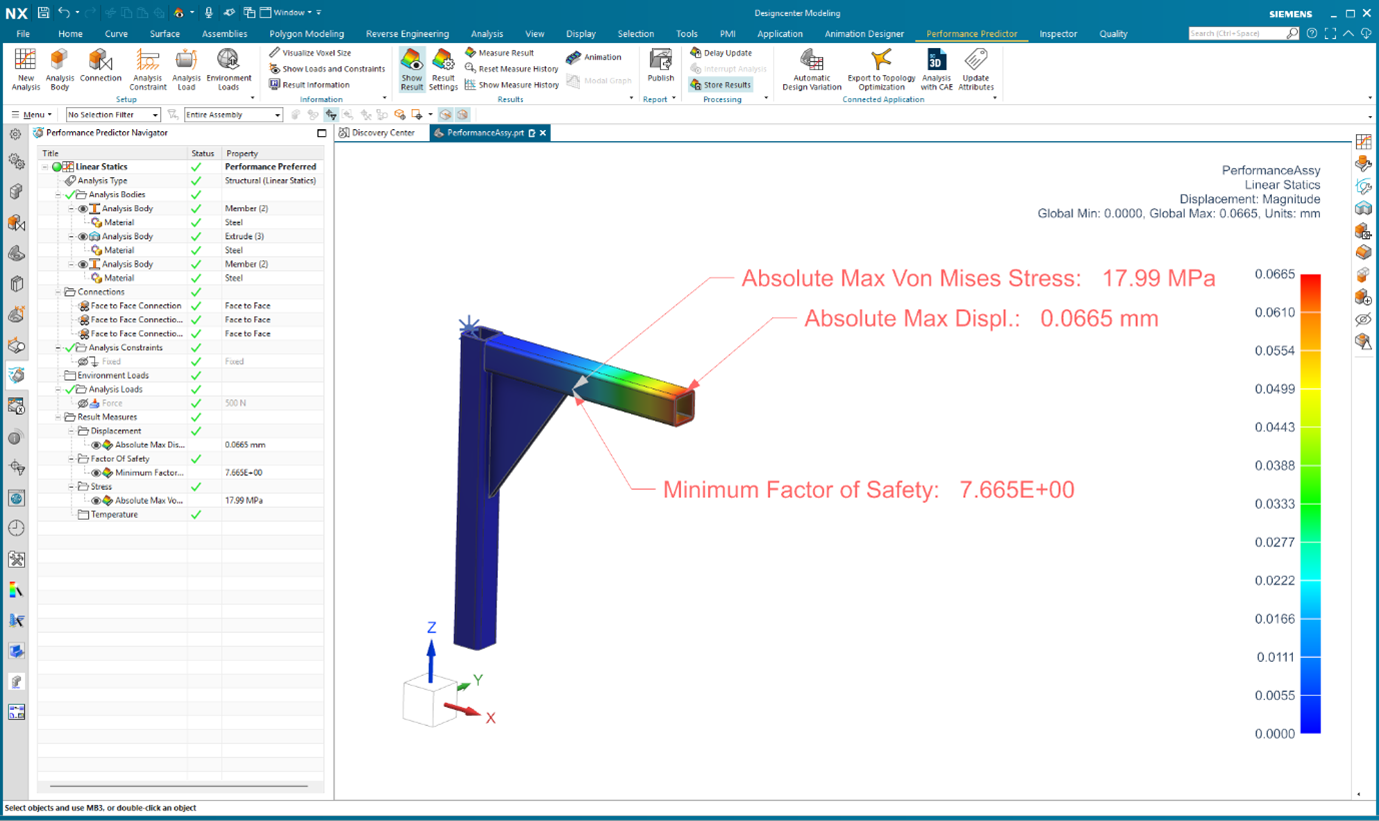

And digitisation is where tools from Siemens Digital Industries Software enter the picture. Specifically, the team relies on digitisation tools from the Siemens Xcelerator business platform, including Teamcenter® software for end-to-end integration, NX™ software for seamless design capabilities and Simcenter™ software for comprehensive digital twin and performance simulation. “The Siemens tools are used by a large proportion of our staff. We are also using a Teamcenter integration framework to integrate the Siemens platform into our ERP solution,” explains Tony Ferrier, head of IT at Cox Marine.

“Teamcenter is used by most of our employees. It is at the very core of our business. It holds all our design infrastructure, so it talks to our NX systems. Teamcenter manages all our documentation – all our bills of materials. This information drives the process all the way from design and engineering to our manufacturing process and production facility.” Getting the whole process up and running didn’t happen overnight. Cox Marine counted on Siemens Solution Partner Emixa, a recognized Smart Expert partner, to help implement the right tools at the right time and to bridge the digital backbone and ecosystem into the company’s ERP and production solutions properly.

“Our IT systems seem quite complex for a small startup, but as the company grows, it is very scalable,” Ferrier says. “We won’t need to make any major adjustments in our infrastructure. Looking forward, we can go from making tens of engines per week to making thousands of engines per week if required.” The experts from Emixa are onsite regularly, making sure that the Teamcenter, NX and Simcenter installations are up to speed and adapted to the growing infrastructure of Cox Marine.

Results

Cox Marine is on the fast track when it comes to growth – the software implementation and the design process run in parallel. The tools that support this team need to be one step ahead of the game and implementing the complete Teamcenter and NX backbone changed the way the team worked.

“We have a large product with 6,500 part numbers in the total outboard,” says West. “For guys working on big sections all day, just letting the tool do its thing, working all day without constantly crashing or freezing with big assemblies open really is one of the most powerful aspects for us.” Another aspect that the design team appreciates is the seamless integration between Teamcenter and NX.

“The best way to explain is that it is practically invisible,” says West. “The guys in the team fire up their terminals, fire up Teamcenter and fire up NX, open the data they need and get on with it.” “If you have thousands and thousands of parts and you are relying on a team of humans to build something, humans are humans, so you will make mistakes. Since turning on all those fancy tools like change control, the vast majority of errors have gone away.”

Explore our Portfolio

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.

Data & Analytics

Expertise in Data Analytics tailors BI & AI strategy, data science, engineering, IoT platforms, ESG reporting, and financial analytics in the manufacturing industry.

Management Consulting

Management Consulting offers strategic guidance in the manufacturing industry, fostering digital transformation and operational improvement.

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.