AESSEAL optimize data control by 75% and improve product quality

Your expert partner in future-proofing yourbusiness to optimize and improve

Business challenges

•Enhance a reputation for excellent customer service and short lead times, worldwide

• Maintain full control of global design and development

• Ensure complete protection of intellectual property in all manufacturing locations

Keys to success

• The ability to establish clear, consistent workflows

• Full control of engineering data publication and revision

• Integration of Teamcenter with other business systems

Results

• Reduces manual data transfer processes by 75 percent

• Complete visibility on all projects enables speedier decision-making

• Tighter revision control supports consistent quality

AESSEAL

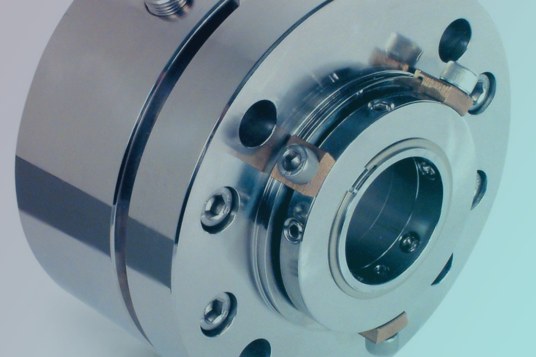

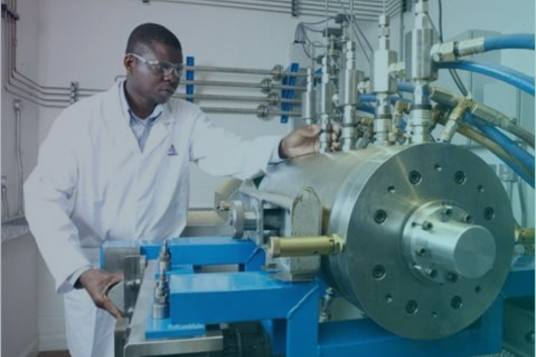

AESSEAL Plc, is a business founded on expertise that focuses on preventing liquids and gases from escaping into the environment. Millions of permutations can be assembled from stock and dispatched within 24 hours, and a database founded on decades of experience speeds the development of nonstandard products. AESSEAL now supplies customers in 104 countries. Stuart Welsh, head of IT explains.

“Our reputation is built on customer service and our speed of response, yet we have gained customers who are far from our original base in the UK, shipping time has become our biggest business challenge. In order to continually improve our customer service, the business recognized that we needed to create a global design and engineering team, supported by local manufacturing capability.”

Business Challenges

Having agreed on a business strategy, it became obvious that existing systems were inadequate. The company decided it was time to implement a more comprehensive product lifecycle management (PLM) solution.

“We already use Solid Edge® and NX™, so the obvious choice was Teamcenter® because we knew that it would support a global engineering and manufacturing facility,” says Welsh. “We undertook a thorough analysis of our business with Siemens Digital Industries Software, and this enabled us to begin planning an implementation project.”

Siemens Digital Industries Software partner Emixa provided a consultant to work alongside users at AESSEAL headquarters. “Through Emixa, we gained one global licensing and maintenance program with Siemens Digital Industries Software and a clear, focused approach to implementation that allowed the business and users to steer the transition process.”

Keys to success

Integrating Teamcenter with AESSEAL's various business solutions, including CRM, MES, and ERP technology, was a crucial aspect of their implementation project. During data migrations, practical issues surfaced, such as the sequencing of actions and specialist team notifications. For instance, design information was typically stamped and published as the final step in development. However, if substantial additional data arrived from the customer, like specific details about the pumped liquid, a revision control had to be issued.

Teamcenter now acts as the gateway for CAD and CAM, with all relevant production data automatically flowing into the enterprise business system upon release. Multiple integration points between Teamcenter and other systems streamline processes. When a design is released, it receives a unique part number, automatically generating stock records and bills of materials (BOMs). Moreover, the "as designed" BOM includes supplementary data like marketing documents with schematics.

Welsh highlights the impact: "The handover from engineering to commercial departments is now faster, simpler, and less error-prone. Previously, we had to manually enter part numbers and descriptions into our ERP system, but now these details are generated automatically. Manual processes have been reduced by 75%, resulting in reliable and consistent data, especially in terminology, part categorization, and posting information to accounts."

Newton adds, "CRM integration with Teamcenter means complete customer details are linked to design information. We're already seeing the benefits. Everyone has a comprehensive view, enabling faster decision-making with accurate information. This will enhance development quality and efficiency, particularly for multi-site projects where teams in different locations can check and review each other's work."

Results

With so many resources dedicated to innovation, AESSEAL registers patents regularly, and the company regards Teamcenter as a key enabler in the protection and advancement of intellectual property.

Welsh explains, “Teamcenter allows us to tightly control who has access to our technology, and this is of clear benefit in situations where our design information is passed to local manufacturers. We have the ability to provide all the necessary geometric detail, yet withhold critical information about the specific application of a product. On the other hand, we can give our customers all the peripheral data they want when we pass drawings to them.Crucial to our success so far is the fact that we can make changes, and we can make them quickly”.

AESSEAL can now focus on the expansion of our business worldwide, knowing that Teamcenter will provide the supporting product development platform for growth.

Explore our Portfolio

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.

Data & Analytics

Expertise in Data Analytics tailors BI & AI strategy, data science, engineering, IoT platforms, ESG reporting, and financial analytics in the manufacturing industry.

Management Consulting

Management Consulting offers strategic guidance in the manufacturing industry, fostering digital transformation and operational improvement.

Product Lifecycle Management

Our PLM practice powers industry innovation through design, simulation, manufacturing, and effective project management in the manufacturing industry.

Enterprise Resource Planning

Our ERP practice leverages SAP solutions to enhance efficiency, streamline supply chains, and improve resource management in the manufacturing industry.

Applications

Our specialist practice for the manufacturing industry creates tailored solutions to drive innovation and streamline operations using Mendix-based applications.

Integrations

Our specialist practice uses Boomi integrations to ensure smooth connectivity and data integration for improved operations in the manufacturing industry.