Manufacturing Menu: Get the most out of your Resources and Performance with the best tools for Utilization and Performance

Last edited on Apr, 17 2024 10:41:54 AM

Reading time: 6 minutes

Written by Chelsea Delich

Table of contents

Manufacturing companies operate in a challenging and dynamic marketplace. They face volatile prices, fluctuating raw material availability and increasingly complex supply chains. In addition, reducing waste is high on the sustainability agenda, and finding enough skilled workers in a tight technical labour market is no easy task.

To strike the right balance between resource utilization, cost optimization and supply chain optimization, optimal performance and efficient utilization of the production environment is essential. By improving the utilization of your factory and the performance of your equipment, you can increase productivity, improve job satisfaction and optimize collaboration throughout the production and supply chain. This is why this part of a manufacturing company's operations has a prominent place in Emixa's Manufacturing Menu.

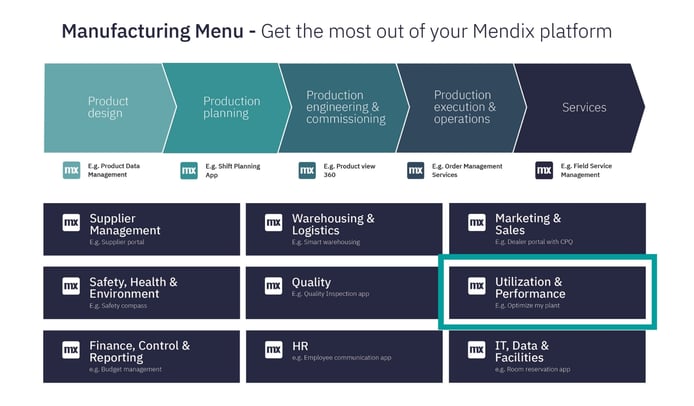

About the Manufacturing Menu

The Manufacturing Menu addresses all stages and areas of production within manufacturing companies, focusing on specific challenges. It offers practical solutions to promote agility, innovation, and adaptability through Mendix's low-code platform. In this article, you will discover how modern applications can help you perfect utilization and performance.

This blog is part of the series: "Manufacturing Menu: Practical Solutions for the Manufacturing Industry" If you are also interested in how a good safety compass and modern, intelligent technology can help you build a solid foundation for safety and sustainability, we invite you to read this blog as well. Discover more here.

The Modern Manufacturing Company: A Close Listener

A modern manufacturing business is a tightly integrated set of processes, people and machines. Machines idling or underperforming because you missed a service? Poor capacity utilization at a particular site preventing you from achieving planned and desired output? Or poor visibility of current production capacity or stock levels causing problems for other parties in the supply chain? These are all complications and problems that can be avoided by using good, modern tools for capacity utilization and performance.

Lost time due to delayed processes, reduced product quality or damage to your reputation due to orders you cannot deliver or cannot deliver on time: these are all possible consequences of poor resource utilization, underutilized capacity or faltering performance.

Better Utilization and Performance with ' Optimize My Plant'

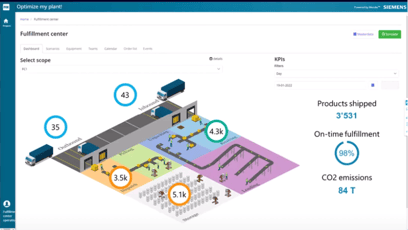

More than ever, manufacturing companies and site managers are under pressure to meet deadlines and optimize production costs, while responding quickly and appropriately to unforeseen circumstances. The Mendix Optimize My Plant application helps you maintain utilisation and performance in such a challenging environment.

More than ever, manufacturing companies and site managers are under pressure to meet deadlines and optimize production costs, while responding quickly and appropriately to unforeseen circumstances. The Mendix Optimize My Plant application helps you maintain utilisation and performance in such a challenging environment.

The application combines several functionalities that are essential for improving utilization and performance. These include powerful and easy-to-use modules that help you plan, assemble and manage teams, and define the plant layout (walking and driving routes, production lines, machine placement).

In addition, Optimize My Plant allows you to benefit from accurate, hard data-based predictions of the variables that have a major impact on the utilization and performance of your production site. Examples include

- Predicting and planning delivery times based on different (alternative) scenarios.

- Predictive maintenance, which prevents production and performance problems by servicing machines at the right time.

- Possible scenarios and alternative production plans that can be implemented in the event of unexpected events.

- Simulations of business and production processes, making it easier to identify problems and bottlenecks.

The great advantage of optimize my plant is that the application gives you insight into your plant anywhere, anytime. All processes and variables that affect your utilization and performance become transparent. The application's ease of use and core functionality also make it easier to improve processes and performance quickly and effectively.

Want to Improve Safety in your work environment?

Making the most of your resources and ensuring excellent performance are key success factors for any modern manufacturing company. Looking to focus on these components of your operations? Curious about how we leverage our knowledge of low-code, Mendix, digital twinning, plant simulation, and Siemens technology can help you with this? Feel free to contact us to explore the possibilities.

Last edited on Apr, 17 2024 10:41:54 AM

Reading time: 6 minutes

Written by Chelsea Delich

Also see..

OverviewManufacturing Menu: A Strong Foundation for the Perfect Product

Before a product reaches the market, a manufacturing company must go through various preparatory...

Read more ⟶Thetford U.S. Perfects EDI Processes and Integration with Boomi and IFS

The American branch of Thetford, a specialist in sanitary solutions for caravans, campers, and...

Read more ⟶Manufacturing Menu: Get a Grip on Your Cash Flows with Smart Financial Management, Control and Reporting Solutions

Although manufacturing companies are primarily producers, good financial management (invoicing,...

Read more ⟶