Get in Touch with Us Today

Start optimising your production processes.

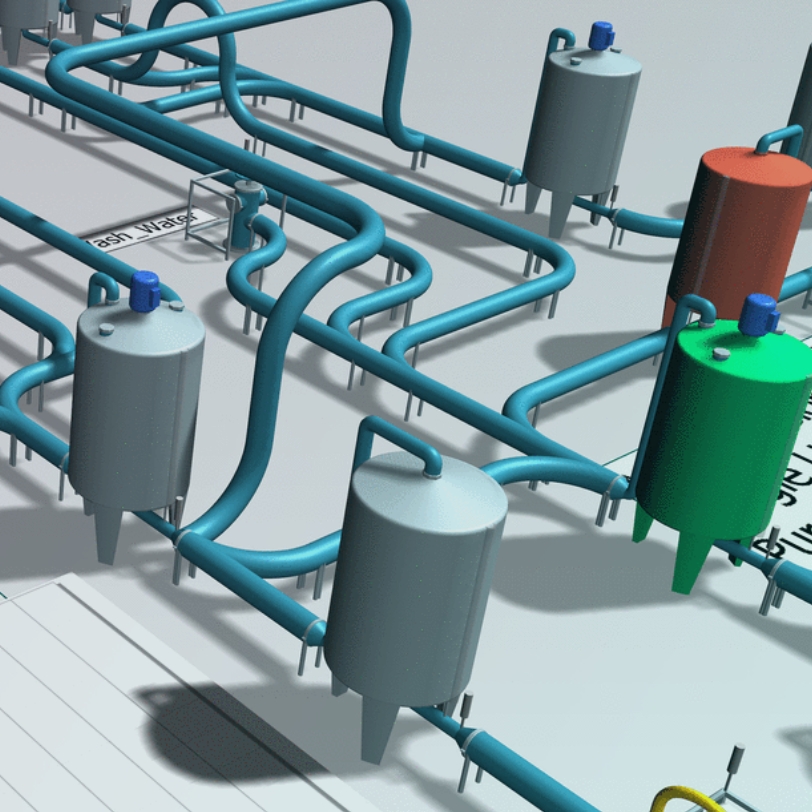

A simulation model or Digital Twin of the production line reveals the interdependencies and bottlenecks among key processes in production environments. It offers a clear understanding of the consequences of adjustments aimed at boosting throughput and flexibility. Furthermore, it plays a vital role in validating changes to production lines before permanent implementation.

We also provide support in relevant cases for reducing machine setup times and energy consumption. Through meticulous analysis of current processes, we can develop strategies that enhance efficiency and contribute to the sustainability of the production environment.

Start optimising your production processes.